Mobile home plumbing is a bit different than plumbing in a traditional home. As a mobile homeowner it’s important to understand those differences.

This article will help you learn exactly how manufactured home plumbing differs from a site-built home and how to repair the most common mobile home plumbing issues. Let me be clear, different doesn’t mean inferior, it just means different.

Major Differences Between Site-Built and Manufactured Home Plumbing

Manufactured homes use the same basics and logistics as a site-built home. The main differences are the location of the pipes, the size of the pipes used, and the ‘simplification’ of the system due to the amazing factory-built system that has been perfected by the industry over the decades.

Supply Line Location

The location of the plumbing pipes is different in manufactured homes simply because the homes are built differently.

Supply lines are what the water travels through to reach each fixture. In site-built homes, they are typically running inside the walls. In manufactured homes, they are almost always buried under the floor as the image below shows.

In manufactured homes, plumbing supply lines run under the home either in the middle alongside your heating ducts or on the side, depending on the layout and location of your water heater.

The image above is a photo of a home being built in a factory. Notice how both the hot and cold PEX water lines are stubbed up through the floor before a single wall is even placed. The construction system, along with the plumbing system, of a manufactured home is simplified for easy transport and installation but that doesn’t mean it’s inferior in any way.

Cleanouts and Cut-Off Valves

Another big difference between plumbing in a site-built home and a mobile home is the lack of cleanouts and cut-off valves in the home though newer manufactured homes have those now. There will be a cleanout where the home’s waste drain line meets the sewer or septic trunk outside.

It’s smart to have cut off valves at every water source (faucet, tubs, and toilet). However, if you have to repair or replace anything on a manufactured home plumbing system you have to cut the main valve off anyway because there’s a lot of pressure in those lines and it needs to be reduced before you start cutting into them.

Plumbing Pipe Sizes for Manufactured Homes

Pipe size plays a big role in a plumbing system. Using pipe that is too small for your venting can cause just as much trouble as using too small of a pipe for your waste line.

Many manufactured home builders install a smaller pipe (3″) for drainage and venting. Site-built homes would have 4″.

Myths about Plumbing in Manufactured Homes

It’s no secret that many skilled trade professionals like plumbers and electricians dislike working on manufactured homes. This is caused by a couple of myths and a couple of truths.

One myth about plumbing in manufactured homes is that there is no venting for the drain lines and that’s ridiculous. All drain-waste lines need venting to even work. Otherwise, the system would become air-locked.

Another myth is that the manufactured housing industry uses substandard and unsafe pipes. Some manufactured home builders did use plastic polybutylene and galvanized metal pipes which were standard at the time for all homes. It was later learned that the material had issues. We’ll talk about that in detail in a few moments.

3 Parts of Manufactured Home Plumbing Systems

Basically, there are 3 parts that make up the whole plumbing system: supply lines, drain-waste lines, and ventilation lines.

Supply Lines

Your water supply lines are the smaller pipes (3/8″ to 1″) that come into the home. They are usually either copper or Pex. If your home has white, cream, or a medium grey pipe for your supply lines, you will probably want to replace them as most local regulations don’t recommend them and some have banned them altogether. The water comes through 1 line and then branches at the water heater so some water can get heated, from there a hot and cold line runs parallel to the faucets, tubs, etc.

Drain Lines

Drain or waste lines are usually 3″ ABS. These systems use gravity, traps, and ventilation to ensure optimum waste removal at the sewer drop and to keep gases and fumes from building up and releasing.

Think of this as a completely closed system with a positive and negative vacuum or pressure. All the parts have to work correctly to allow the system to do what it is designed for. Without the proper positive or negative pressure acting as a vacuum in the pipes the waste won’t go where it’s supposed to, it can back-flow instead.

You have to get the grade right on drainage pipes because too much of a grade (or slant) will cause as much issue as too little. A 1/4″ to 1/2″ grade per foot is ideal.

Ventilation Pipes

Ventilation pipes help the waste lines to keep the proper pressure or vacuum – in other words, it keeps water in all the right places. It is just as important as the supply and drain lines and you have to have ventilation in order to make it all work. Plumbing systems are much like a living thing – it has to have air and water.

A single ventilation pipe in a manufactured home won’t help the drain pipes furthest away so they use what I’ve always just called a dry vent (they also call them auto vents, check vents, or air admittance valves).

Air Vents

Air vents allow air to flow into the drains. Keep in mind that oftentimes a dry vent on a sink isn’t necessarily helping the sink it is tied into, it’s benefiting the other drains in the house. If you would like to learn more about auto vents, this article does well explaining, as does this one.

Under Pressure

Remember that water is coming into your home under a lot of pressure through your supply lines. It can turn corners and go up several stories. If you have a leak in the system, imagine how much water can be lost in just a small amount of time!

Drainage leaks are sneaky little things. Water will always follow the path of least resistance so sometimes it’s hard to pinpoint where the leak is coming from.

Common Plumbing Pipe Materials

You will need to know what type of pipe and fittings are used for each sub-system. There are basically 2 types of piping used in plumbing- metal and plastic.

Most plumbing in manufactured homes uses plastic. Plastic pipes include polyvinyl chloride (PVC), chlorinated polyvinyl chloride (CPVC), PEX pipe and PolyPipe®. Metal plumbing pipe consists of copper, stainless steel, and galvanized steel. Not all pipes are as useful or effective as others, and each type is used for a specific purpose in plumbing.

Polybutylene Pipe

Polybutylene was used in all types of homes, including manufactured homes, from the late 1970’s to the mid-1990’s. Several lawsuits were filed on behalf of millions of homeowners due to issues this material had. If you had any type of bleach in your water, and most city systems do, the pipe would break down and cause leaks and complete blowouts, usually within 5-10 years. You can’t buy it anymore but it’s still in more homes than it should be. It’s a medium grey color and will have PB and some numbers on the side. If you have this in your home today, you need to replace it and then go buy a lottery ticket cause you have been very lucky to have had it this long without any issues!

If you are looking to buy an older manufactured home, do not buy it with this kind of pipe in it. Make the seller replace it or have them take the replacement cost off the price of the home (there may even be local and federal laws prohibiting the sale of a home with this type of pipe in it).

PVC

PVC is a type of plastic plumbing pipe primarily used to transport high pressured water. It is available in several standard sizes, ranging from ½ inch to 4 inches in diameter. PVC pipe is only made to handle cold water, as hot water will cause the pipe to warp. It is generally white in color, though a few varieties are gray.

CPVC

CPVC pipe that has received an extra chlorination. It comes in a distinctive yellow color and can handle both hot and cold water. CPVC is more flexible with substantially thinner walls than PVC pipe and has the same outer diameter as copper pipe, which increases its range of uses.

PEX

PEX, also known as cross-linked polyethylene pipe, was first manufactured in the 1920s but has become more popular in recent years. It shares the same outer diameter as copper and can be used for both hot and cold water. However, PEX pipe has a much higher heat resistance than most other plumbing pipes and is often used in water-based heating systems. It comes in a creamy white color, as well as red and blue which is used to denote hot and cold pipes respectively.

We recommend you replace your water lines with PEX when the time comes to update. You can use special fittings to secure the connections by hand or rent the tool needed to connect the lines. Pex, in our humblest of opinions, is the best pipe for water supply lines and is so much easier to install than anything else.

PolyPipe®

PolyPipe is a thick black pipe used to transport highly pressurized water, usually to and from the home. It is used almost exclusively outdoors and is usually buried underground to prevent freezing. PolyPipe® is extremely rigid, and is rarely used for other purposes.

Here’s a good video about a double wide re-pipe:

Copper

Copper is the most common type of plumbing pipe used in the home, although it is more expensive than plastic piping. It is especially resistant to corrosion and can withstand high temperatures. Copper pipes come in three different sizes – type M, L, and K. Type M have very thin walls, while type L is of medium thickness, and type K is the thickest of the three.

Galvanized

Galvanized pipe is known for rust issues and the plastic piping (polybutylene) are known to corrode and cause leaks. There’s also an issue with the connections. If you find yourself plagued with leaks, go ahead and re-pipe the home, if possible.

Galvanized pipes have been used in homes for years, typically to carry water in and out of the house. The galvanized coating prevents rusting and gives a dull gray appearance. Use of these heavy duty pipes is diminishing, as it is being replaced by PEX pipe, which is less expensive and just as durable. Galvanized pipes typically come in sizes between ½ inch and 2 inches in diameter.

Common Plumbing Issues in Manufactured Homes

Nasty smells and weird noises

Ventilation issues are very common in manufactured homes. The most notable problem being nasty fumes and a build-up of gases that could cause some serious issues.

Ventilation makes your pipes remain at a neutral pressure. Without proper venting, your drainage slows and the water in your P-trap goes away, which in turn allows the nasty smells to escape into your home.

Think of a soda bottle: when you tip it half way, the liquid smoothly flows but when you turn it completely upside down, it makes gurgling sounds and the soda pours out slowly. That’s what happens when there’s not enough ventilation or air flow.

There are wet vents and dry vents, the roof pipe is considered a wet vent.

If you hear weird sounds coming from your walls when the water is draining (not when water is running) you most likely have a venting problem.

Venting issues are hard to find. The easiest cases will either be a clogged vent stack, separation of a vent line somewhere, or a failed auto-vent under a sink.

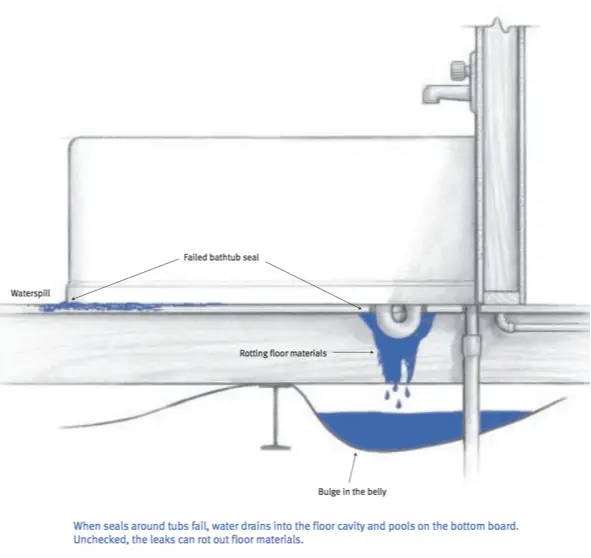

Plumbing Leaks

Plumbing supply lines in manufactured homes will rarely be inside a wall so you won’t need to worry too much about damage to walls. When there is a leak it’s usually the floors, sub-flooring, insulation, and HVAC ducts under the home that get damaged.

If your flooring is made of composite wood or MDF it will soak water up like a sponge. Wet MDF eventually bows and rots.

In the end, it will be far cheaper, and less stressful, to just cap off the old lines and run new water supply lines than trying to fight with old material and patches.

Area plumbing codes will be the ultimate factor in deciding what material to use but Pex is a popular product and as long as the connections are high quality and a proper seal is made, will be your best choice for supply lines.

A monthly check under your sinks and under the home itself is a good idea.

Leaks, clogs, low pressure, obnoxious odors, and having no hot water are just a few of the issues that you may encounter. If your manufactured home is older you may have to replace the system entirely. There are lots of things that can go wrong! We’ll try to cover them all in the future.

Leaking Faucets

Leaking can occur in a couple of different places on a faucet. It’s probably easier to just replace the whole unit than repair. If you are especially attached to your faucet, this article about fixing leaking faucets should help.

Clogs in your kitchen Sink

If there is a clog in your sink, a plunger can work well. They make a smaller plunger for the task. If you have a two-sided sink, close off one side by stuffing a rag into the drain (cut off air) and plunge the other side, then switch – keep doing it until the clog is gone.

If you have clog issues frequently, it may be time to find the underlying issue. You can remove your p-trap, if it’s closed off with grease you can clean it out or replace it. You may need to add a dry vent to the next closest sink.

How to Turn Your Water Off

Knowing where and how to turn your water off in case of an emergency, or before any repair, is important. Being able to shut your water off quickly can be the difference in a complete disaster and a small inconvenience.

The first place to go is the main stop valve for your home which should be around your utility room or around your outside garden hose water connection (hose bib as some call it).

If you can’t find your home’s main stop valve you’ll need to cut the water off at the main water meter (assuming you are on a city system) or in your pump house if you are on a well system.

Most city or town supplied city water systems require a water meter key. This is a five-sided pentagon wrench that unlocks the meter cover. They come in different sizes so check what size you need.

If you can’t find a meter key you can also use a wrench and long screwdriver for a makeshift key – place a wrench straight up and down and then thread the screwdriver through the hole at the end of the wrench. The two tools will look like a T. Use the screwdriver to turn the wrench. This article about turning off your water supply is handy if you want to read more.

Once you get the cover off the water meter cover you’ll see a knob or nut that you can twist to turn the water off. To work on the home’s plumbing system you’ll need to drain the supply line system so the pressure is released.

We’ve covered the basics of plumbing in manufactured homes: how the systems work, where everything is located, and what your choices are for pipe materials. We also covered the 5 most common mobile home plumbing issues and how to troubleshoot them.

Our article, How to Diagnose and Repair Venting Issues in Your Mobile Home Plumbing System, can help you learn more about venting issues.

Thanks so much for reading Mobile Home Living!

Featured Image: 37 Sequoia Circle, Santa Rosa CA listing photos.

Thanks for the sharing.

I have a 9 year old manufactured home and I have a leak in the master bathroom tub area. It has a partial wall between tub & toilet. At the base of wall, water is leaking out. I’m trying to find shutoff to that tub. I shut off water to toilet but the tub is confusing me.

I was washing dishes in kitchen sink and all of a sudden I lost almost All water pressure in kitchen and pressure in sink in guest bathroom only hot&cold on both sinks ..where should I look its an older trailer ?

I was washing dishes in kitchen sink and all of a sudden I lost almost All water pressure in kitchen and pressure in sink in guest bathroom only hot&cold on both sinks ..where should I look its an older trailer ?

Dorothy, I needed plumbing work in both my bathrooms. I was having quite a bit of work done. Complete new roof and subflooring which is a pretty frequent problem. Well I received 3 estimates for repiping since my mh is a 1990 my lowest estimate was just under $13,000 and then I’d have to retape, repair the underbelly. Well no repipe was done and the contractors couldnt replace my cracked and leaking tub or touch the cracked pipe that I found behind the tub and son’s closet. This took place right when the clovid close in began also I live south of seattle. And let’s think about how much it would have been once they started. And the fact that I cant even put my head in and look under the house. Not good news and not happening. Good luck on your pipes and hopefully the county codes are not like here.

How can one find a plumber who works on mobile homes?

I noticed there is water leaking from the side if the roof by the gutter. It is happening whenever I run water inside the home. This Mobile home was built in the 70’s. Any suggestions?

Check with your county code enforcement. They will know what type of permits you will need.

Do you have heat tape installed? That’s the easiest way to keep pipes from freezing.

I has a cracked abs drain pipe which replaced with pvc and recommended glue for the transition from abs to pvc. Cleaned and disposed of waste and threw lime under mobile home. Sometimes still get a foul smell in different areas not near drains. Is there something I can do, check or use to fix this?

I am trying to locate my shut off for my outside spigot. I went to the hot water tank and see there are 2 shut offs. One close to the floor and one going to the pipes for the hot water tank. Are either of these for the outside water?

My mobile home is a 1973, they sealed the belly and put insulation in but I have problems with pipes freezing up, is there anything that can be done about that

I live in Washington State. How does one go about finding codes/laws for renovating a mobile home?

Thanks for your help.

Hi David,

As far as I know, it wouldn’t be an issue. The water in the lines doesn’t stay hot for long. Thanks for reading!

Hi Gladys,

You probably could repair it but buying a new one would probably be cheaper and easier. Unfortunately, they just don’t make them like they use to so don’t expect 40 years out of the new one. However, you may luck up and find some parts at a local small appliance shop. Best of luck!

Hi Micheal,

The white pvc part is likely a regulator though you can buy inline boosters that give your hose more pressure. Thanks!

Hi Dave,

Finding replacement parts for manufactured homes is a big issue, unfortunately. You may be able to find it at Mobile Home Parts Store here. . We’ve usually just replaced the entire faucet rather than having to deal with the finding parts though. Best of luck!

I need to replace my bathroom faucet aerator assembly. The original housing is plastic and chrome plated. I cannot seem to find it’s replacement. I can find ones with 1.5 gpm but was hoping to find its original of 1.2 gpm. Is it okay if I replace it with a kit from Home Depot that is metal and chrome plated? Or do I still need to look for it’s exact match?

I have to replace the old galvanized pipes, including the hose spigot, that the feeder line from my park main attaches too. Is there any kind of pressure regulator in this section of piping? There is a white pvc part, about 3 inches, prior to the connection to the homes actual plumbing lines.

Your supply water has nothing to do with the drain water & its venting. You simply got ripped off by the “plumber”…because you don’t bring a snake out where there ain’t water running to be plugged. Insulate your supply line or watch the weather for temp drops below freezing so you can have your cabinet doors open to allow heat to the pipes as well as let the faucet drip slightly during the cold snap. Remember…No Water..No Snakes!

Wouldn’t the Hot/Cold lines too close together possibly create condensation ? Just a thought. Not a plumber. Lol.

Mobil home built 1971-1975 stove / separate oven not working can we repair

Hi Barb,

One of your elements may have burnt out in your water heater.

We live in a 3yr old park model and have noticed this past week we need to run the water now for it to get hot

Does this sound like something serious may happen?

Hi Dorothy,

I wouldn’t be able to give you an estimate without an inspection to see what needs to be done. Fortunately, most plumbing companies will give you a free onsite estimate. Best of luck!

I’m looking to redo the plumbing to a double wide home can you give me a ballpark figure for that type of work

Hi Sandra,

It sounds like a clog somewhere. You may need new fill valves in the toilets (if it’s the tank that is filling up in the other bathroom). Best of luck!

Hi Alex,

It sounds like you have a clog somewhere. Cut the grey line, find the clog and blow it out, or install a double shut off valve. Best of luck!

Hi Jesse,

Backflow from washers are usually a clog somewhere but if you have a new washer you may want to try a bigger drain line to give the water more room to flow. New washers are powerful and need 2″ drain lines. I don’t really understand why the plumber couldn’t at least enter a snake into the trunk line and make sure there wasn’t a clog near your kitchen though. Good luck!

My washer is backing up in the drain pipe but my kitchen sink and dish washer is flowing. Plumber said he could not snake it.

Hi Brittany,

It’s probably just a loose connection somewhere on the showerhead. It’s usually cheaper and less hassle to buy a new head and install it. Let me know if that works.

I have a cold water issue coming from the small bathroom toilet when filling the tank. It’s filling the sewer pipe in the master bedroom toilet. There is no water turned on to the toilet or in the tank at all. Water streams in a little at a time with each flush of the other toilet. The water is clean. How can this be??? Thanks for all the information on mobile home plumbing

Question: I have a newer mobile home and just replaced the dishwasher. Sharkbit the old grey line into the new metal line and added another shutoff valve. The problem is that no matter how many times I turn the shutoff to wide open, I get maybe a quick spurt and then nothing. The dishwasher will not fill despite the line being open and the sports making it through both valves. Help!

Hi Jackie,

Yes, it is possible and we highly recommend it. It’s a smart update to any home but especially in a mobile or manufactured home. You should be able to do it yourself just be sure to use the higher grade braided lines.

Is it possible to add shutoff valves under the kitchen sink and bathroom sinks? I hate that you have to turn everything off if you want to change something or if there’s a leak. Mines 2002 double wide.

Hi Rocky,

A mobile home approved water heater (especially if it’s gas) is best. Otherwise, your insurance company can deny claims should any issues arise (even if it’s not related to the water heater).

In a 1970 mobile home before HUD

Can a regular water heater be used

Like in a regular home?

Hi Leah,

The 1/2″ will get you how water faster on that other side of the house which is always a plus. You’ll want to strap the PEX (just ask your plumbing supplier for strap, it comes in a roll so you can measure your own). I do want to clarify that when we say to install your water lines close to your ductwork, we don’t mean right up against. We just mean within the same cavity. Ideally, strapped up against the flooring as closely as possible so that the constant heating and cooling from the ducts don’t make the PEX brittle. You should be fine running the PEX side by side but some plumbers like to keep them 4-6″ apart for some reason (easier to work on maybe?).

Best of luck!

Hi Dave,

This one has stumped us. We’re perplexed. Apologies!

Hi Michael,

It’s probably gonna be easier to just pull the plumbing instead of the vent since the shower drain is 2″ and the bathtub drains are usually only 1.5″ (though you could use a bushing but that will make it drain slowly). Good luck!

Hi Marie,

Check to make sure your auto vent is working under the sink (assuming you have one). If that doesn’t work, check to ensure your vent stack coming out of your roof is not clogged and that sufficient air can move in and out of it. Third, make sure there is no grease buildup in the pipe. With grease, a drain king sometimes can’t do anything because the grease just closes right back up after the drain king is pulled back out. If it is that bad replacing the line is about the easiest way to fix it.

best of luck!

Thanks for the tip, Suzette! I never heard of that but it makes sense! Thanks!

In addition to letting your faucets drip, (all faucets,

including the shower), opening your cabinet doors and shower doors is also helpful as it allows the warmer room air to get into the cabinet and shower area nd raise the temperature of the air circulating around the pipes. When its really cold outside, especially at night, we do this to every sink cabinet and shower in the house and we have had a lot of success wirh it.

I have a newer double wide with water problem. There are two bathrooms and three bathroom sinks. When I turn on the cold water side after a few seconds a smell comes out that disappears in about ten seconds. I have a well water source with good water. All of the lines coming up thru the floor to the sink have been replaced. I even replaced the faucet in one bathroom with no change. No other lines in the trailer produce a smell. Any ideas?

Hi,

My name is Marie and I own a 1989 Champion single wide 14×80. The issue I am having is that my kitchen sink is extremely slow draining. We have used a drain king, no luck and replaced the drain vent under the sink and it is slowing even more. any suggestions?

I have a 1994 single wide that I bought a couple years ago. I have the dreaded polybutylene so I’m looking at a full re-pipe this summer. I’ll be doing it mostly by myself since I live in a state where homeowners can do their own plumbing. I’ll be doing everything with pex and I think I have most of it figured out but there are a couple of details that I don’t know about. Most of the plumbing -one bathroom, kitchen, laundry- is on the end of the house where the water heater is. I have another bathroom that is 40-50 feet away on the other end of the house. I plan on running a 3/4 inch cold line to the bathroom and branching off from there (sink, toilet, shower, and possibly a new hose bib outside in the spot). My questions are: should I run a 3/4 inch hot line there or is 1/2 inch enough to supply both the sink and the shower? And how should I support that long water line under the house? It will run down the center of the house in the cavity along the heating duct and then sideways between the joists to the bathroom. The belly is in great shape all the way so I’d rather not slice into it a whole lot but code says it needs to be supported every 32”. I’m not suuuuuper worried about code but I want it to be safe. How much can I rely on the insulation and the belly itself to support the line? What kind of support do you suggest given that I’ll have minimal access to the joists from underneath and I probably won’t even have enough space to swing a hammer when I’m under there? I won’t be removing any of the polybutylene so if it’s well supported, would tying the pex to it in some way be ok as support? (Thinking with zip ties, perhaps)

Another question is about how to support the line that will cross the center of the house, over the heating duct to the opposite wall where my kitchen sink is. The duct itself will give some support but it’s metal and I know I need to minimize friction. What’s the best way to protect the pex in that instance?

And lastly, how separate do I need to run the hot and cold lines? I can’t think of a good way to keep them apart as they run through the channel down the middle of my house and since I live in a northern climate I don’t want to insulate either or both of them against the warmth from the floor above. Would the hot water lose a lot of heat if it runs right next to a cold line?

Thank you! I love your page.

Question: I have a plumbing problem. 1985 doublewide mobilhome. I am replacing the old garden tub with a shower pan. After taking out the tub I found a surprise, the drain is on top of the floor running into the vent pipe then down to the main line. As i will have to move the drain to place the shower pan, i was planning to building a platform for the shower pan, rather than try to move the plumbing from the vent. I will have to extend to drain another 6in under the platform in order to fit the shower. Any thoughts or suggestions?

Absolutely! We’ve always done it when it gets really cold. Just a slight drip is fine – you just want movement in the pipes. If possible, let the faucet that freezes most drip or the faucet furthest from your inlet/water heater.

Is leaving a faucet running a little cold water to avoid pipes from freezing a good idea for mobile homes, as well?

Hi Lindsey,

You will want to let them cut the wall out from the backside. It’s going to be a lot easier to deal with because the surround on your tub is glued in and any kind of modification to it will likely cause a leak and you don’t want that. You can buy decorative panels to put over the opening but with the right technique, you would never know there was a panel cut out from the wall. I bet the plumber will know how to do it, too.

Hi Carole,

The vent on your roof only affects the waste lines, not the supply lines. You probably had a little section of pipe that was frozen and the snake just didn’t reach it. Good job keeping an eye on everything though – a lot of people wouldn’t even attempt to learn how things work.

Hi Dave,

Ideally, you really would want the lines to run close to the vent/ducts of your furnace (if you get freezes) and above the belly wrap because you don’t want any holes in it. You can always patch the belly with some tape (though don’t buy the belly tape they sell at the mobile home supply store, you can find better working tapes at Lowe’s. Other than that, you have a good plan. If you can, take some pics along the way, I have a hard time finding images for DIY articles. Thanks! Best of luck!

Hi Janet,

First, you really need to get the leaks fixed. Read this article and see if there’s anything in it that could help you. $40 worth of PEX and a couple of fittings could save your home from utter destruction and there are Youtube videos you can watch to help you do it yourself. Once the leaks are fixed then you can replace the soft subfloor and build the floor up to the wall.

Best of luck!

Hi Paul,

It sounds like you need to replace your pressure reducing valve or your backflow preventer. They can malfunction easily. Best of luck!

Hi Stacey,

So, it sounds like you have a volume problem more than a pressure issue. When you changed the main metal line was the pressure reducing valve replaced as well? You did great by updating the lines and that probably fixed a huge part of your issue (closed pipes) but if that pressure reducing valve wasn’t’ replaced it’s holding your volume back which is acting like the original problem even though it isn’t (I hope I’m explaining this well enough to understand)…With water lines, all of them should be under the floor. You don’t want to have to replace ceiling panels if there’s ever a leak.

Best of luck! Let me know about the PRV. I’m almost certain that’s the issue.

Hi my name is stacey I have an older mobile home still has the grey pipes under it. So the past few years I have had an issue with water pressure. Found out while doing some trouble shooting that I still had metal pipe under the ground. The metal pipe was changed last year and after that I cleaned out the hot water tank and change the elements that still made no difference in my water pressure and it’s both hot and cold. It has gotten to the point now that there isn’t even enough pressure to run the shower. Last winter my water froze and the pressure got 100 times better but since it’s gotten to be the worst it has ever been. So I changed a couple of the t’s leading to the hot water tank and the pressure is still low I didn’t even see any thing in the t’s but my thought is since when I turn the water on I get a rush of water then it dies right down so there has to be a clog in the line coming in some where. That being said I’m a single mother and I am not crawling under my house my thought is to bring the waterlines into the house and have them run along the floor or ceiling. My other question is in doing this should I stick to 1/2 inch pex or just run 3/4 inch pex? I know one of the t’s that I changed the cold going to the tank was 3/4 inch and then t’s to 1/2 inch. My thought is if I go with 3/4 inch there will b less of a chance of getting clogs in the waterline in the future. Also would it be best to run the hot along the ceiling or the floor?

Hi Steven,

You probably just need to clean out your aerators on your faucets. Let me know if that works!

Hi Kimberly,

I know I’ve answered this comment before but my commenting system in on the fritz so I’m answering it again, sorry. You should have received an email with my first answer.I’m thinking you don’t want insulation on the interior walls of your water heater closet so that the heat from your home helps keep the closet warmer which makes the water heater work a little more efficiently.

You definitely want insulation on the exterior wall though.

Hope that helps!

Hi Neal,

I know I’ve answered this comment before but my commenting system in on the fritz so I’m answering it again…your lines have been crossed somewhere under the home and it’s gonna be a heckuva chore to find where it occurred and then fix it. Unless you are really comfortable with plumbing you may want to hire a pro. They can probably spot the issue quickly and get the lines straightened out. You’ll def want to get it done as hot water used in toilets is going to waste a lot of electricity and wear and tear on your water heater.

Best of luck!

Hi Ron,

You will need to flush your water heater and lines out ASAP. You have some growth going on (from the non-use and the warmth). Don’t drink it until it’s well flushed. Here’s a few videos and articles on flushing water heaters.

Best of luck!

Hi Richard,

I want to say this is a remnant of a recirculation system maybe? I asked my husband and he didn’t really know either. Heat tape without the tape? I would remove it for sure though. Best of luck!

I hope you don’t mind this inquiry. I have a 22 year old double wide

mobile home made by Chandeleur Model 2810-3B2. We started having

fluctuations in our water pressure about a month ago (sometimes it was strong

sometimes low with all faucets). This week the flow has been starting out strong for a few seconds, then

goes low (less than half normal). Our outside faucet is part of the main line going to the house

yet it’s flow is strong and doesn’t fluctuate. We do not have hard pipes, they look more like hoses

PEX I guess. Haven.t yet had any luck finding how to talk to Chandeleur to see if they installed

a filter for our water system. If you have any advice or insight to help me correct the problem

it would be appreciated.

I bought a 1981 single wide a few years ago. for a couple of years all that leaked were a couple of windows. I had custom windows put in. Now the problem is leaks keep sprouting from the nasty blue pipes and I can’t keep up. I have nasty smells under my kitchen sink. Hallway sinking, and one bedroom has a floor that is coming apart from wall where my daughters bed is. I am afraid mold is growing somewhere where leaks are and were. What should I do. Can’t afford the high prices the plumbers want to reinforce flooring and replacing pipes?

Hello. Thank you for your terrific advice in this website. I’m in Central California (Sacramento area) and I live in a 1977 mobile home in a senior mobile park. The mobile home has the original galvanized steel fresh water pipes. The pipes have corroded and the flow is greatly reduced, especially the hot water, and not the cleanest. I am going to replace the pipes with PEX. (I won’t be removing the old pipes.) My plan is to have a Hot manifold and a Cold manifold (or a combination hot/cold one) and use the home-run design to run individual water lines to each fixture. The original fresh water pipes are run above the “belly” covering and I don’t want to cut into it to run the PEX. Can I run the pipes and hang and attach them below the belly cover? Then just go thru the belly cover where I have to attach to the fixtures? If yes, anything I need to watch out for? Any advice would be appreciated.

Kind regards,

~ Dave

I own a single wide mobile home. Last winter i lost all water in the bathroom for about 3 days. I assumed it was frozen pipes and brought in a plumber. After snaking the lines for about an hour and a half, he determined there was no plug, and he couldnt find any freezing. He was unable to help me, charged me for his time and left. I had mentioned that the roof vent over the bathroom was buried under the snow but he kept insisting that wasnt the problem. I will mention that water was completely fine in the kitchen at the opposite end of the mobile. The water heater is in the back bedroom. We were having a very cold snap at the time. After three days, the water returned in the bathroom and everything was working fine. The pipe of the roof was clear at that point. Is it possible the buried pipe was the issue? Should I have the pipe extended so that doesnt happen this winter?

Hi Rosie,

I’d need a lot more information about the home, the noise, and the drain before I can offer any guidance. What type of home, what type of drainage system (city sewer, septic, etc), type of noise, what’s the pipe look like?

Hello, we’re so very confused about how the plumbing work in a manafacture home. My son just bought his first home, this home is a newer model, but he noticed water draining out from a pipe and we can hear some kind of noises under the house, it sounds like a pump. Is this normal?

Hi Angelo,

Absolutely, you can (and should) run the ice maker line under your cabinet. Use straps or J-hooks to attach it to the highest, out of the way, place you can. Best of luck!

Hi Angelo,

Yes, you absolutely can run your fridge water line under your cabinets. It’s pretty standard in all homes. Make sure you have it protected well (maybe strap it directly under the counter) and be cautious that its there (checking for leaks on occasion). Best of luck!

Hi LaVee,

You have a partial clog that is holding water in your trunk line. The other bathroom would be fine since it ties into the trunk line at another point. A plumber could come in and jet the line in an hour.

Hi Timothy,

Assuming this is your foundation drain, then yes, it’s fine and doing its job. If you are talking about a waste line then you have a serious issue.

Hi Arthur,

No, your cleanouts should never be glued. In fact, they are threaded so they can be easily removed to cleanout the pipe. Now, sometimes, the material warps in heat/cold a bit and tightens itself so much that you’d think it was glued.

Hi Kathy,

These days, we use washing detergent that is too sudsy and our washer drains are too small so this cause all kinds of trouble. You probably have a clog in your drain line to the trunk. You need a plumber to go in and jet your pipe. You could do this yourself (you sound handy) but knowing where and how to place the jet (drain king if you do it yourself) is vital so you don’t blow out something somewhere else. Best of luck!

Hi Tracy,

Sounds like your cold water line is clogged somewhere. Look around your faucets, shut-offs and T’s. Best of luck!

Hi Mark,

So, you may want to look at your refrigerant/heating/air copper lines – those sizes are different from plumbing. Also, if they used rolled soft copper it will go into an egg shape and size weird. With those, you need to reftrofit and adapt. Also, look at the ID (inside diameter) and OD (outside diameter) – pipes are measured differently in some ways.

Best of luck!

I have a 1993 Fleetwood doublewide mobile home. The problem I’m having is when I run the dish washer, use water in the kitchen sink or the laundry room…water backs up in the master bathroom in the tub, shower and toilet. The bathroom on the other side of the house has no problem. I have tried liquid plumber several times and it it will eventually drain, but when I use the water again in the kitchen it backs up again. If I do nothing it will also eventually drain. Also, after it drains and no water has been used for a few days, I can use the dish washer and there is no backup in the tub…but if I continue to use water it backs up again. Again the other tub, toilet and sink never back up. Any suggestions would be greatly appreciated. Thanks

Hi Marcia,

I’m doing a complete makeover in our master bath. Drain and supply lines were above the floor. The tub was already on a styrene platform so no issues since I was putting it back in place. I removed the fiberglass shower enclosure and I’m replacing it with a real tile shower. The shower drain and supply lines are above the floor. I rerouted the 1/2″ water lines into a wall but could not lower the drain lines. So the shower drain line and vent valve had to stay in place. I placed 2×4’s on the floor 8″ apart 2 high, screwed, glued and leveled to the original floor. That gave me the 3″ I needed to get above the drain line. Put a subfloor on top of the 2×4’s also screwing and gluing. Built the rest of the shower floor on top of that. The vent is in a corner so I’m building a corner seat to cover the 8″ sticking up and also extending the vent line into a adjoining linen closet in the bathroom.

Not sure if my comment got through.I have a 2016 Atlantic double-wide manufactured home and am looking to do a new install on a fridge ice maker water line. The fridge is on the opposite wall of the sink. Can i run a water line under the floor to the sink, this would mean removing the home’s skirts and crawling under the floor to run it to the sink. My question is what is needed for this and what precautions do I need to take to make sure the line does not freeze in winter. I live in Maine so it can get very cold.

I have a 2016 Atlantic doublewide without an ice maker line for a fridge. I am looking to purchase a new fridge with an ice maker line, problem is the fridge and sink are not on the same wall. Can I run an ice and water line under the floor to the sink, this would mean drilling a hole where the fridge will be and crawling under the floor on the slab to run the water line to the sink. Is this possible and what precautions do I need to take to make sure the line doesn’t freeze in the winter.

I have a mobile home that has some low pressure on the sinks, but shower and baths are OK. Also low pressure on the icemaker and dishwasher. I am at a loss.

we get a musty/funky smell in our water (mostly hot water?), the worse early in the season or when the water is not used for a weeks at a time. Is this a hot water tank issue?why the smell?

Hi Karen,

Absolutely! You may need to buy connectors to reduce or expand your original pipe in order to use your new faucet (they often include them in the box). I do recommend that buy a good quality name brand faucet (Kohler, Moen, American Standard, etc). Best of luck!

Hello. I am recovering from a disastrous water heater installation which flooded my 1976 Fuqua home requiring removal of floors and walls in several rooms. Here’s my question…after three months of dealing with terrible service, the restoration company left my outside water heater closet without the paneling that was originally there until I showed them a photo showing it was paneled before mitigation started. I finally got to them reinstall paneling, but they refused to insulate the walls inside it which are kitchen and laundry room walls. They said you don’t insulate those. However, the walls in these areas are nothing more than 1/8″ particle board and you could see daylight through the outlets when the paneling was down. We are talking paper thin walls that move when you push on them. I have convinced them to blow insulation in there now but they say I will need to heat that closet in winter to avoid freezing since the heat from the house will no longer be doing the job. I live in Bend, OR and it gets extremely cold here in the winter. We have a lot of snowbirds here so I can’t imagine that what they are saying is true since those folks leave their homes for months without heat on in the house. I just want to put this issue to rest and ran across your site. I have had two plumbers tell me there should be insulation in the walls to my mobile home especially due to it’s age. Who is right? THANK YOU!

I have a 76 mobile home that we have a leaky faucet in the shower and possibly need to replace the actual valves to the sink and the shower. Can regular valves like from Lowes be used or do I need to get special mobile home valves?

I just moved in to a triple wide manufactured home. It has two water heaters, one in furnace area and one on the other end closer to the bathrooms. The toilets are connected to the hot water as are the outside sill cocks. Any suggestions?

I have a 1988 Fleetwood single wide. A bottle of shampoo fell and broke the cold water knob off the faucet in the tub. The so-called “repairmen” I’ve had come to look at it want to cut a hole in the adjoining room to get access to the piping behind the tub surround. They won’t guarantee that they won’t damage the paneling and/or trim in the adjoining room. I have redone the walls with wallpaper and paint, which wallpaper I doubt is available anymore. Now I’ve replaced a tub surround before and I think all that needs done is to take the panel off where the faucet and shower head are over the tub to get to the piping. This might require cutting a portion of the surround, but it could be replaced and the seam covered with trim once the repair is made. These guys want a minimum of $500 to do this repair. Since I’m a senior citizen on a fixed income and have made many repairs to mobile homes and “regular” homes over the years, I see no reason to pay this amount of money for what should be a fairly easy repair, if you actually know what you’re doing. Does my method of replacing this faucet sound do-able or am I being unrealistic?

I recently bought a mobile home up north.

I have a small object under the bathroom sink which has a metal tube running into the drain pipe. The tube is about 1/4″ or 3/8″. There are three wires exiting the object, which are not attached to anything. Any ideas what this system is?

This might help. There is an element which warms the cold water pipes to keep them from freezing.

Thanks.

I have a 4 inch pvc pipe that runs at a slope covered under earth from our 32×80. We have had an extreme amount of rain lately. Water is running at a pretty steady pace from the pipe. The problem is I have never noticed water coming out of this pipe before. Someone once told me If I see water coming out of there I have a real problem. Could it be the 4 inches of rain we have gotten or is there a problem

Thanks Tim

manufactured home,kitchen sink empties into a 4 inch drain pipe that goes all the way under the home to the septic ,on end of the 4 inch drain there is a clean out plug screwed into it. question is that plug removeable or do they glue them in upon install of home?

Hi! I have a 2002 double wide Palm Harbor. My washer, when on spin cycle, would back up my kitchen sink. I ran a 25′ snake thru the sink and cleared whatever was in there…sink is good now. However, I can’t run my washer due to the water backing up thru the outflow pipe. I have removed the “p” trap behind the panel at the washer and run a 25′ snake back towards the kitchen…. Still backing up the outflow pipe. Even ran a snake from the roof down..no luck. I’m trying everything I can think of before cutting any pipe under the house. Any suggestions? Thank you in advance.

Also, how can I get my hands on any plumbing schematics?

Hi Rick,

Those hoses are not very expensive so go ahead and replace it. There are some products that seal well but it’s not worth the time or the cost when the hoses are so affordable ($30 or so should get you a good one).

Thanks!

Hello I have 88 single wide, leaking water under valves for washing machine, small hole in hose, I taped it but just made it stop spraying…, can these hoses be repaired or just replace?

thanks

Hi Mary,

Yeah, it was probably leaking within days of the install. Lots of people forget the basics like gaskets and tape (or just don’t use them if they don’t have any handy). Also, sometimes the plumber will not buy all new guts for the shower to try to save money or time. Attaching new to old can be tricky if you don’t know what you’re doing (and don’t understand expansion and contraction).

So sorry this happened to you.

Hi Marcia,

That’s a question I can’t really answer without looking at it. Some manufactured home builders will raise the tub to gain proper grade. Those usually have a step that’s not part of the tub.

Sorry I cant help more!

Hello,

It sounds like you need to find where your lines tee off of the main water supply trunk (or line) under the house and reverse them. For the faucets, you can switch out the lines under the faucets. You’ll probably want to call a plumber for the toilet – they will be able to get those lines switched out pretty quickly.

Best of luck!

I have a 1998 mobile home. my plumbing in the 2 bath no cold water anywhere so no water in toilet but if I take a hot shower then my toilet fills up with hot water. in my master shower I only have hot water also and in the sink. but the toilet works fine. kitchen sink both hot and cold works. Any ideas Thank you

Hi, We are snow birds living in a 1973 double wide. The main bathroom has a raised tub I would like to replace with a shower. Are the pipes raised under the tub making a major replaced job or is the tub on a platform that will make it much easier to replace? Thanks.

Hi Crystal: I have a 1989 mobile home and about a year ago I had my smaller bathroom redone, tub/shower, toilet and sink. Recently I started smelling something and had my UN-Licensed (my fault) installer come check it. He came out and said he found a leak in the shower water line in the wall (he had to cut an access area to get into the bathroom plumbing. After he didn’t come back out and fix it I called a plumber with 40 yrs experience. He fixed it and told me it was a rubber gromet/gasket that was missing. He said my original installer should have seen the leak from day one and never closed up the access panel. He believes my leak was from day one of the install. Could this likely be true?

I have a 1963 10×50 Ranchero mobile home with copper water supply lines. The plumbing runs along the inside wall in a enclosed box. The hot water line has a leak which requires splicing in a a new piece. The problem I’m having is finding the right size of copper tubing. The leak was caused from line freezing and blowing out a old repair. The size must be between a 3/8 and 1/2. I have tried both sizes and its either too small or too large. Could it be that the whole pipe swelled from freezing? I’ve been told that these old mobile homes have odd size plumbing. I cut out a 6′ piece thinking that would eliminate a swell problem, but no luck. Do you know the proper size copper tubing for this mobile home? Thank you.

I have a 1999 Champion Doublewide home. On one side is the laundry room and master bath. The water on side A operates normal, hot water runs hot water and cold water runs cold. Side B has the kitchen and the 2nd bath. On side B the hot water faucets run cold water and the cold water faucets run hot water (reversed), this would also include hot water flushing the toilet on Side B. How is the water connected under the home when it is set up. What is the easiest way to find where the water supply was hooked to side B. I am assuming that once I find where the supply lines were connected, I can reverse them and then side B will operate normal including the toilet and shower.

Hi Tyler,

It sounds like you have a leak. Look in your yard and under your home for soggy soil or water. That’s where your leak will be.

Best of luck!

Hi Terrance,

This is a mystery for sure but I think you have dirt clogging the screen for your pressure reducing valve coming from the main water line into the home. All that construction probably loosened up a lot of stuff in the lines. If that isn’t the case you may have to check all the screens for dirt on everything you own (washer, water heater, etc) (you may want to do that after you clean the pressure reducing valve anyway.

Best of luck!

Hi Michael,

I guess it would be worth a try to extend it but that’s the usual length. Sorry!

HI. Ok I’ll try to sum this up as quick as possible. I live in a mobile home. Nothing special or out of the ordinary. This summer a construction company was making a lagoon sewage pond thing. They were taking lots and lots of water truck loads of water from the fire hydrant located outside my home. I noticed the water would get very rusty and weak. At times, it would all up and stop working. When they finished the lagoon. My water pressure wasn’t normal. I’ve never had any issues with water pressure at all. We have city water hook-up. The strange thing is, after i cleaned the aerators out and bled the flex lines, the washer machine and bathroom pressures stayed insanely low. The toilet takes forever to fill back up, the cold water in the shower and washer machine barely work. When the washer machine is on the cold rinse cycle, I turn the tub cold and hot water on full and the pressure in my washer machine speeds up and it’s warm! Not cold. Like the hot water is having back-pressure or something. So that’s bacially it, in a nutshell. Oh yeah, the trailer does not have a pressure tank thing in it either….. I hope you have some tips or an answer. Thanks so much!

I have a 1978 skyline 70×14. I’ve lost a bunch of water pressure and my meter is going nuts, so I shut the water off. What’s the best way to go about fixing it?

Hi Brandi,

You can Google sink and faucet replacements and find some great videos of the step-by-step process. They will give you a lot better info than I can just typing it out. The process for manufactured home replacements is similar to a site built home. I’d probably go ahead and replace the faucet while you’re doing the sink replacement. You’ll need to consider your counters (weight limitations and framing will be the two major issues to consider – mobile home sinks are usually low weight and are installed with clips).

Best of luck!

I’m in a Fleetwood doublewide, 25 years old. I have a shallow double aluminum ? sink in kitchen. I want to replace with a deeper, single sink. I need to know everything I will need to replace to do this. The drains are corroded and the pipes underneath would need to be for a single drain. I am pretty sure I have room for an 8″ deep sink – the pipes can be shortened, I am guessing? Any info, diagrams, wisdom would be greatly appreciated. I am so tired of wiping splashed water from these shallow basins. Thanks!!!!

Hi Katie,

Absolutely! You’ll just remove the toilet and cap off the lines under the floor. You can usually patch the subfloor so you won’t have to replace a whole sheet. It’s a very common remodel.

I have a new 16×80 getting a smell once and a while off the back deck nothing in the house and at the end of trailer .Do think my vents on the roof need to be higher they are only about 8 to 10 inches ???

i have a 1993 double wide home and i have zero use for the toilet in on of the small bathrooms. So, I was wondering if there’s a way to get rid of the toilet and permanently seal of the toilet drain, so that i can get rid of the bathtub and put in a huge shower. if i were to leave the toilet in. I wouldn’t be able to put in a master shower.

Hi Edward,

The first thing I would do is replace the wax ring on your toilet. It sounds like that could be it – it would only leak when flushed (or backed up if your trunk lines are a little off).

If that isn’t it, it may be supply lines or drain to your new vanity. Test them under different scenarios (flush, use the tub, check the auto vent, etc).

The tub could be seeping from the supply line or the drain, too. If your washing machine is close it could be back flow (the drain lines are usually too small to handle these fancy new washers).

You have one of those problems where you just keep testing and trying different things. Let me know what it ends up being.

Best of luck!

My question is I have a 2005 double wide… The floor in the spare bathroom is wet.. but no water line leak because floor drys. Check water meter water meter stay still.. I was thinking it was a drain.. I had taken out the vanity.. run a water hose down the drain.. turn the water on for an hour still no leaks… I climbed under the house look for water leak felt around nothing.. around toilet dry OSB was soaked now dry don’t understand..

Hi Jamie,

My first thought was the wax rings but if the plumber replaced them then it just about has to be a simple pipe disconnect probably right under the toilet. You replace wax seals from in the home so unless the plumber crawled under the home first he would have likely assumed it was the wax just as I did (wax seals go bad more often than pipes disconnect so can’t really blame him). The disconnect would cause an unbalance in your vent lines too.

That would be my guess anyway. Best of luck! Let me know how it goes.

I have a doublewide mobilehome. Under my guest restroom there is water pouring out anytime we flush or let water run down the pipes, i do not however see any poop or smell anything unusual there. The toliet in the guest bath water value is shut off because water was comi g out from under it when it was flushed. Can you please explain how to fix this and maybe why it contiunes to happen? I paid a plumber over $900 because he said it was the wax seals and he replaced those and also put in a vent pipe for the washer. I need to get this fix asap. The sinks do gurgle when flushing or if the tub is draining but there are vents under the two sinks. I am not sure what the issue is. Please if someone can explain how to fix this. The big black pipe still seems to be pushing stuff to the septic and nothing is washing back up the pipes i just have no clue. Thanks!

Hi Lee,

That’s a possibility, I suppose. Just be proactive and check for leaks routinely. If you can poke a hole or two around your water fixtures (especially toilets and baths) you could give the water an escape route and a way to detect leaks. Plus, whenever there is a leak that wasn’t detected quickly you can almost guarantee that flooring will need to be replaced anyway, especially if its original particle board sub-flooring, that stuff just soaks the water up like a sponge. I think you’ll be OK.

Due to flooding, our belly bag and pink insulation was damaged. We had to remove it all. We decided to spray foam the underneath. Since then, a prospective buyer informed us that in the event of a plumbing leak, the water would have no where to go and would travel upwards into our flooring and we would not realize it until it was too late. Could this possibly be true? Thank you for any help you can give. Lee

Hi Patrick,

I’m no plumber (and I’m no longer married to one) but I’m thinking you have a blockage in the line from the water heater to the faucet. Water heaters catch a LOT of settlement from the main water lines and it can build up in the lines (especially around the connections). I would try to snake it out and make sure the connection at the water heater is clear.

Best of luck!

It could be a couple of things: you may have a slow drain due to a slight blockage, you could need a larger pipe from the washer, or you could need better ventilation. A plumber could probably tell you immediately. Sorry I can’t be more precise!

Hi Dan,

I would contact the roof installers and make them open up the vent line (and add a wire netting over it to keep critters out). It sounds like you have it figured out. Roofers should know how important proper air flow is to a home’s ventilation lines.

Best of luck!

I recently had my asphalt shingle roof replaced with a metal roof and I’ve noticed that the sewer vent stack(s) were not carried through the metal roof. Since the metal roof installation, I have an occasional sewer odor in the kitchen and always notice sewer odor on cold mornings outside my back deck. No sewer pipe leakage to be found and all plumbing seems to be working properly. My guess is that the sewer gases from the vents are being trapped between the home plywood roof and the metal roof and are entering either through a kitchen gravity vent or range exhaust hood that were also not brought through the metal roof. The contractor says he installed 100’s of metal roofs this way and has never encountered a problem. Your thoughts on this , please.

Why does my ???? gurgle when washing clothes when it drains

I’m in a mobile home.do I need a new septic lines

Hi Crystal, I have a question concerning plumbing in my mobile home. I cannot get my hot water to work out of the kitchen sink faucet. The hot water runs fine in all other faucets. I undid the line from the hot water handle on my faucet. I have no water running thru the main hot water line. I also undid the cold water line and I have water coming from the main line. That told me it was not the faucet. I climbed under the trailer to check for broken water lines or leaks and found nothing. I’m perplexed as what it could it be. I had the kitchen and faucet replaced 6 months ago. I do know the old version had a pressure relief valve sticking out the top of the sunk. The new one does not and the installer stated it was not needed. Do you have any idea of what my problem could be?

Hi Robynne,

I have added your name to our email list (I took it off the sidebar with an intention of creating a new one but I forgot to do it – thanks for reminding me!) I do have a form that is supposed to popup but it doesn’t seem to work very often.

You will need to confirm that you really want to receive emails from me so when you get an email pleases click the confirmation link and that will get you started.

Thanks so much for your kind words! I bet your home is going to be gorgeous!

(PS I’m newly divorced after 19 years. It’s a lot of change all at once but I think it’s for the best. I hope you will be able to say the same!)

Best of luck!

Hi Crystal,

I’m so appreciative of this website that if you were here in person I’d hug you. Hard. I’m newly separated (after 27 years) and 62, and just purchased a 1991 14×70. It’s in great condition cosmetically, but I’m pretty sure there are a few hidden surprises.

Do you have a regular blog that I can sign up for? I’ve searched high and low on many of the articles, but can’t find anything that would allow someone to enter an email address.

If there isn’t a blog, I’ll settle for your gold mine of information, and just search for whatever I need.

Thank you for sharing your knowledge! You’ve made an old woman a little more relaxed.

Thanks so much Lee!

I just met with a plummer about my mobile home water heater. I’m not certain if there is, or isn’t, a “special mobile home water heater,” but I do know that mine is “for use only in mobile homes,” according to the owner’s manual (Kenmore model #153.333850). The plummer told me to NOT have a handyman drain the sediment out because it is a lot more involved process, requiring disconnecting a few things before draining. He also said that they are not the same as in regular houses.

Thanks for the info. HUD regulations are, in all reality, absolute minimum safety standards which is why state and county code always trumps it. I do need to research and make sure that’s the case in all states though (I know we can use water heaters from Lowe’s in WV).

Unfortunately, the master plumber and I are now divorced so I can no longer get his advice. I did Google search a bit and came up with the following links which may help answer your question:

http://www.hotwater.com/lit/training/320991-000.pdf

http://www.familyhandyman.com/plumbing/water-heater/replacing-a-water-heater/view-all

http://www.homedepot.com/c/how_to_install_gas_water_heater_HT_PG_PL

Thanks so much for the info. I’ll clarify my answer in the above comment.

HUD requires that a water heater be certified for mobile home use.

http://plumbing.about.com/od/water_heaters/a/Mobile-Home-Water-Heaters.htm

And there seem to be 2 types (for gas), direct vented and one in which DV is not required.

The DV type prevents indoor air from mixing with combustion air. Air gets sucked in from the top or bottom and escapes through a roof jack.

The other kind (for gas) is less expensive, and is allowed only in mobile homes that have a special access door from the outside to the water heater compartment.

But both (plus the electric kind) have this odd side inlet for the cold water, and I’m still trying to figure out why it can’t be piped into the top, as it is in houses. Maybe it has to do with the water coming up through the floor, but I don’t see the big deal in having another 4 feet of plumbing which would obviate the need for a special type of more expensive water heater, apart from the venting, which I would think could just be added onto a standard unit.

Hi John,

All builders will have complaints and each area of the nation likely have different builders and, of course, dealers so that’s going to influence complaints and reviews. Do tons of research for your area, use some of the tips on here and you should be able to get the house you want at a fair price. Best of luck!

great information , need to know I am looking for a manufactured home and I like Karsten , but also skyline, but skyline has a lot of complaints , not as much as clayton , who I will not touch ,, any suggestions would be helpful

Mark,

Mobile home water heaters meet HUD code. When we replaced our water heater we went to Lowe’s and bought one but I suspect some states like California have a much stricter code. (Thanks Lee for the info!) You will need to choose between low boys and high boys and electric or gas. You’re looking at $300 max. Your codes will vary by state and county but there’s not a whole lot of variance from site-built homes. PEX is used often with shark bites and standard transitions from copper.

Best of luck!

How does the mobile home plumbing code differ from any other when it comes to replacing the water heater? I know I need a special water heater (around 500 bucks) but can I pipe it just like a normal water heater with copper pipes attached to the Pex pipes?

Hi Bill!

If I had to guess, I’d say you have a blockage in your shower body valve (the guts behind the wall). Your line goes from say 1/2″ to 3/8″ or 1/4″ in there and that narrowing gets clogged with sediment.

You can usually access the body valve via a bedroom closet through the opposite side of the wall (there’s usually a panel). Take the new shower heads off and blow it out. That should help!

Best of luck!

Hi Kim,

In this case I would probably just make sure I had easy access to a main shut off valve under the home (before the water enters the home). Along with a ‘key’ to shut off the city water and a whole home shut-off valve you should be fairly well protected. Lots of homes already have a main valve shut-off and it’s usually located close to or with the water hose connection. As long as you can get to that main valve to shut off all water you should be OK (make sure there’s access to the valve in the skirting – a door or a panel works well).

Best of luck!

Hi Kevin,

Look around your back door or where your water heater/utility/laundry room is located. It’s usually about 6-12″ back from the edge. Best of luck!

I have a 1989 Marshfield home single wide, I trying to put a shutout valve in my cold water line but it does,not come up by the hot water tank. The main cold water line does not come up throw the at all. One line straight to the hot water tank,No splits when the line goes straight to the hot water tank. So the main cold water is underneath the floor, The ownly way is to cut into the floor to put a main water value inside the home.

Hi Andre,

How odd! Your outside water valve is likely really close to the water heater, usually around your back door. Best of luck!

I had a plumber come by and install a new waterline for my icemaker. I now have no water to my outside lines, front and side of the unit. Where can I find the outside water supply valve?

Hi Heather,

You probably have a clog at the tee on the cold line at your water heater. It’s likely clogged after it feeds cold water to the water heater, that’s why you have hot water pressure but not cold. It’s probably gunk in the lines where you hooked to the old line in ground, happens all the time.

Best of luck!

Hi Dan!

Yes, the vent pipes are 100% dependent on the layout of the drainage/waste pipe under the home. The previous owners probably capped off some old pipe or rerouted pipe and maybe couldn’t reach the original or had a clog/issue in it… but that kinda perplexes me because opening up the roofing and ceiling seems to be a lot more trouble than reaching the original vent or repairing whatever issue it may have had. I’m not a fan of making holes if it’s not 100% necessary, especially in the roof. If the original vent isn’t being used at all it’s probably a good idea to cap it off and seal it up completely so no leaking can occur.

You can use in the wall auto vents in a lot of situations. Take a look at this article: https://mobilehomeliving.org/manufactured-home-plumbing-drainage-and-ventilation-issues/

If you have any more questions just reply or create a new comment. I try to check them at least 1-2 times a week. Thanks so much and best of luck to you!

This is a great article that helped me understand better how my piping works, but I have more specific questions that I cannot find the answer to anywhere.

The previous owner of my home made some of the plumbing a little wonky and there are two vent pipes (I assume) going to the roof in the bathroom. Both are 1-1/2″.

Are both required? Is it dependent on how he did all the plumbing underneath (he replaced the ancient metal pipes with plastic). Would any harm come from relocating one, that is really my problem one as it’s done in a way that prevents a large chunk of the bathroom from being used for anything but pipe-space. And can this pipe, and others, be inside a wall?

I cannot afford a plumber, so I’m trying to learn what I can, but the internet is surprisingly sparse on mobile/manufacture home literature.

Just came across this awesome website! We just replaced a broken pipe between our well house and our home. We came inside and took the screens off of the faucets to clear the lines. Cold water throughout the house has really low pressure and one of our toilets won’t fill. Hot water throughout is good and the other toilet in house (farthest from the repair and where the water comes into the home) is good. Is this something we can track down and fix or is it time for a professional?

Hi Sherrie,

Sounds like you have it! With PEX sticks you should be able to cut a small slit just at the connections so you won’t have so much belly wrap to tape back up. If you use PEX rolls, you can thread it through but lay the pipe out a couple of days before the project to get some of the curl out of it. Threading it with a long stick helps a lot. At all your fixtures stick the pipe down through the floor first and then go under the home.

Your skirting and pipe insulation is going to be your biggest protection against freezing. In WV, we only add tape to the pipe in the area between the ground and the inlet. I will not use insulation sleeves over tape (and I’m not sure it’s advisable in a lot of cases). An insulated box built around the pipe from ground to belly is a good idea too.

Best of luck!

I do live in the north (Ohio).

This is the way I’m picturing what you’re saying for the new Pex — order from ground up: Belly wrap, trunk line, insulation, sub-floor/flooring. Branch lines go straight through floor from fixtures (if not using old holes), through insulation (no fishing), connected to trunk line — all as close to venting (ducts) as possible. (Thus, I’ll have a continuous slit in the belly wrap several feet long — following the trunk line and connections — to seal with belly tape.)

Much less complicated and much less work than I was anticipating.

Another question. It’s been almost 20 years since I lived in a mobile home, so forgive my lack of memory . . . the heat tape then wraps as much of the trunk as possible to keep it from freezing, right? In other words, should the tape go as far on the trunk as my farthest branch connection? Or do I create a fire hazard since it would all be — or a big part of it — inside the belly? (From what I understand through other internet reading, the installed heat tape and pipe gets wrapped with insulation.) (Until I started reading about heat tape installation, I didn’t even realize there are tapes especially for plastic pipe.)

The heat tape is gone, so I have no clue to follow. The lady who owned my trailer is in a nursing home now (never got to speak with her) and the relatives winterized it. I believe they removed the heat tape while doing so.

P.S. All my site-built homes have had basements and easy access to plumbing. That’s why I’m making sure I understand you correctly. I never had to work on the one-and-only other mobile home I lived in other than to replace heat tape. Even at that, I just followed where the old one had been installed. I don’t remember it going any farther than where the pipe entered the belly.

Thanks, Crystal, for sharing your knowledge. Big help!

HI Sherrie!

First, keep in mind that you will never be able to repipe your home exactly how it was from the factory – they ran the pipe before the flooring and walls were installed and may have placed the pipes in the middle (usually) or on one side or the other, depending on the layout.

Your best bet when doing a complete repipe with PEX, is to just cap off the old water lines at the floor of each fixture and run new PEX.

If you have no flooring and easy access, perhaps pulling your subfloor up will be easier but in most cases I think working from underneath is less hassle. If you can cut/cap off the old pipe under the floor and use the same hole in the floor for the new pipe that’s great, if not, no big deal.

You can drill a hole in the floor and punch the PEX through the insulation and belly wrap (just so you can find it). Once you’ve found all your PEX under the house, run your trunk line (preferably under the insulation and over the plastic belly wrap). You can tape the belly wrap back together with belly wrap tape. You’ll use the access panels to reach the ‘guts’ to the showers (if you don’t have one you’ll need to make one on the back side of the shower).

By running all new pipe and capping off all the old at each fixture, you won’t need to worry about where the old pipe is. By leaving the old pipe in place and capping it off at each fixture you will be saving time (especially important if paying a plumber by the hour) and dump fees. You won’t be fighting with running the new pipe through the drilled holes, etc. It’s just an overall less-stressful way to re-pipe a mobile home. I can only think of a couple of scenarios where removing the old pipe and running the new through the exact route is beneficial or worth all the extra effort.

Your new trunk line could be ran down the middle of the home or on one side depending on your layout and where your water heater is. Just figure out a route that uses the least amount of pipe (and cuts/transitions) to reach all your fixtures. You’ll want your pipe to be as close to the venting as possible if you deal with cold winters (not a big deal if you are in CA, FL, etc).

I like to recommend re-piping the whole house if you’re having a lot of leaks or if your home is very vintage and original. Might as well do it all if you’re already down there!

Hope that helps. If you have any more questions just reply! Best of luck!

This probably seems obvious to others, but not to me. To replace plumbing (water lines), do you access the lines by opening up your flooring or opening up the belly? It seems like I’d be disturbing too much on the underside if I went up through the belly, but don’t relish the thought of going through flooring. I watched a YouTube video of a man demonstrating Pex replacement in a mobile home. He opened up the flooring but doesn’t explain much — not even demonstrating how to use the crimper. (I already know how to do Pex, familiar with the tools, etc. I’m a landlord and have done it on one of my rentals. EASY & FUN!)

If I open up the flooring, is it easy enough just to open a small area and ‘fish’ the new Pex to any other area in the home where I make another small opening to grab the Pex through?