Many mobile homes built before 1976 only have between 1 and 4 inches of poor quality insulation if they have any at all. Even if the insulation was installed, many builders left voids and gaps throughout the home. Fortunately, manufactured home builders have gotten a lot better after the HUD code regulations began and, of course, there have been significant advances in mobile home insulation over the last 40 years. Installing insulation in a mobile home is one of the best home improvement projects you can do.

Installing insulation in a mobile home can reduce your utility costs and increase your family’s comfort drastically.

In this article, we take a look at mobile home insulation. There’s a lot to sift through when it comes to mobile home insulation. Why do you need it? What is it? How do you measure it?

Advantages of Install New Insulation in a Mobile Home

According to the Department of Energy, mobile homes built prior to the 1976 Department of Housing and Urban Development (HUD) codes have a special need for added insulation. Even newer homes can benefit from added insulation.

Advantages of New Insulation in a Mobile Home

Reduced Utility Costs

According to the Insulation Institute, homeowners stand to save 15% on heating and cooling by adding insulation to the home. This number actually increases in older homes, since in many cases they’re poorly insulated to begin with.

Increased comfort

Adding new mobile home insulation is not all about saving money. There’s definitely something to be said for increased comfort. Having a better-insulated home makes it easier to stay warm in the wintertime and cooler in the summer.

What Does R-Value Mean?

Different insulation materials will have different R-values. To choose the best insulation you’ll need to consider the installation ease or difficulty, the costs, and the R-Value you get for your money and effort.

When discussing mobile home insulation you hear a lot about R-Value but what is it?

In general, heat flows from warm areas to cool areas. During the colder months, the warmed air inside your home will be trying to flow out. In the summer, the hot air outside will be trying to flow indoors. This phenomenon is called conduction and convection. Let’s break down how this law of nature interacts with materials in your home:

The ability of a material to resist heat flow is measured by its R-value. The higher the R-value, the more effective it will be at insulating your home.

Conduction

Conduction refers to how heated air travels through materials, and insulation works to alter this conductive property. With the right conduction protection, less hot air will flow out through your walls in the winter.

Convection

Convection refers to how heat circulates through the air. Stopping this flow of air via convection within walls or openings controls energy usage.

Most Popular Types of Insulation

Let’s break this down a little further by looking at some of the most popular types of insulation.

Blanket; Batts and Rolls

This is the most common type of insulation out there. As the name suggests, it’s found in the shape of batts (rectangular pieces) and rolls (cylindrical pieces). It’s made of flexible fibers and can be cut to a width where appropriate. This makes it a good choice for between stud and joint spacing.

Foam Board

Where batts and rolls are soft and flexible, foam boards are quite rigid and provide excellent thermal resistance. Foam is used for new roof overs and has proven to be a good product to insulate and act as a belly board for mobile homes. You can see how one industrious couple used foam board to insulate under their mobile home here.

Loose Fill or Blown-in

As opposed to the previous two types of insulation, loose-fill/blown is composed of small particles that can be used to fit into virtually any space with amazing flexibility. That’s why this type is great for areas that have obstructions or oddly-shaped spaces and older mobile homes.

Sprayed Foam or Injected

Foam insulation has become more common over the last few years. This is a unique concept because the foam is liquid in its container (can or box) but once it’s sprayed it foams out and expands in every direction and then hardens. Foam insulation fills even the smallest of spaces to create an air barrier.

Injection foam is generally used in enclosed spaces like walls. Some energy efficiency experts have questioned the ability of foam insulation. Testing has shown that the R-Value of foam sprayed insulation is not as good as regular batt or loose fill. It’s also a messy product and can quickly get into places you don’t want it.

Popular Materials used for Mobile Home Insulation

Each of the types of insulation we just discussed can be made out of various materials.

Fiberglass

Fiberglass insulation is a great choice for insulating homes and is the most commonly used insulation in manufactured homes. It doesn’t burn or rot.

Fiberglass is really a fiber-like material made from glass. In fact, its structure is made from molten glass that is formed into very small fibers.

Advantages and Disadvantages of Fiberglass Insulation in Mobile Homes

Advantages of Fiberglas Insulation

Fiberglass is made of soft fibers, which means it’s very flexible. It is also a very effective insulator and cost-effective which is why it’s been a favorite insulator for homes for decades. You don’t need any specialized tools except breathing masks and skin protection.

Disadvantages of Fiberglass Insulation

Unless you use plastic-sealed batts, fiberglass can trap moisture but it doesn’t deteriorate much when it gets wet, it just loses its effectiveness.

As far as health goes, the small glass fibers of fiberglass can be dangerous to breathe in, damaging the lungs and provoking allergies when inhaled. It can also annoy your skin. Fiberglass insulation’s R-value also decreases over time as it settles. And unfortunately, critters love it.

Lastly, batt insulation is installed incorrectly more often than you’d think. Homeowners tend to install batt or rolled fiberglass insulation inside out which reduces its efficiency drastically.

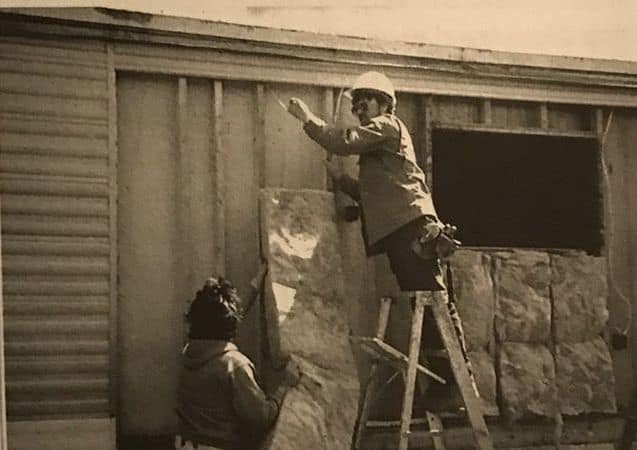

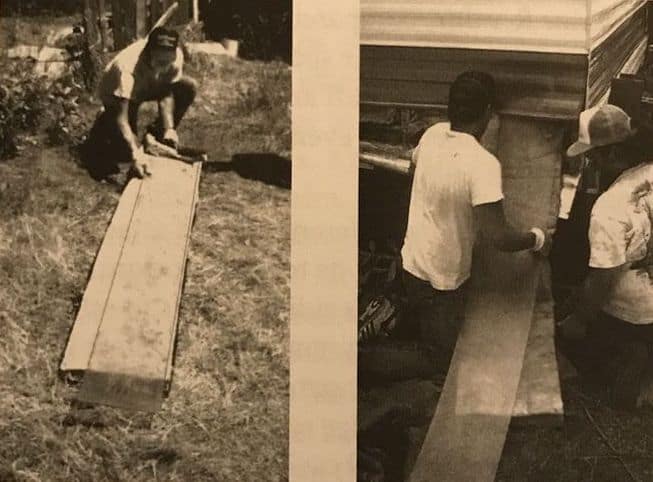

Batts of insulation being installed on a mobile home.

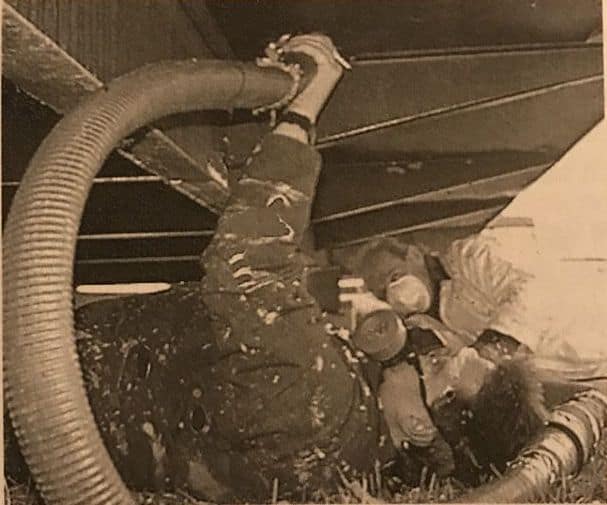

Insulation being blown into the subflooring of a mobile home.

Two Types of Fiberglass Insulation

Fiberglass insulation is available in rolls or batts and through a system that blows loose fiberglass into an area.

Blown Fiberglass

Blown fiberglass insulation is the top choice for mobile home energy efficiency experts. The construction of mobile homes, with all the tight areas, makes installing batt insulation difficult unless you are doing a complete remodel. That’s why blowing in insulation is the best choice. A long hose shoots the material into small places like above the ceiling or between the floor joists.

Batt Fiberglass

When one thinks of batt insulation they think of the Pink Panther because one of the most popular fiberglass insulation brands uses the cartoon character as a mascot. Batt or rolled fiberglass insulation should never be squished as its the combination of air and glass that creates the insulation. Many brands have paper or plastic to make installation easier, also called faced.

Batt insulation is mostly used between studs in mobile home walls though many have used it between floor joists. These batts can come faced or unfaced. Faced means there is a plastic or paper sheet attached to one side that makes it easier to handle and install. You just staple the paper to the studs as seen in the photo below.

Most energy efficiency experts recommend UNfaced batts to re-insulate mobile homes.

Blown Fiberglass Versus Fiberglass Batts or Rolls

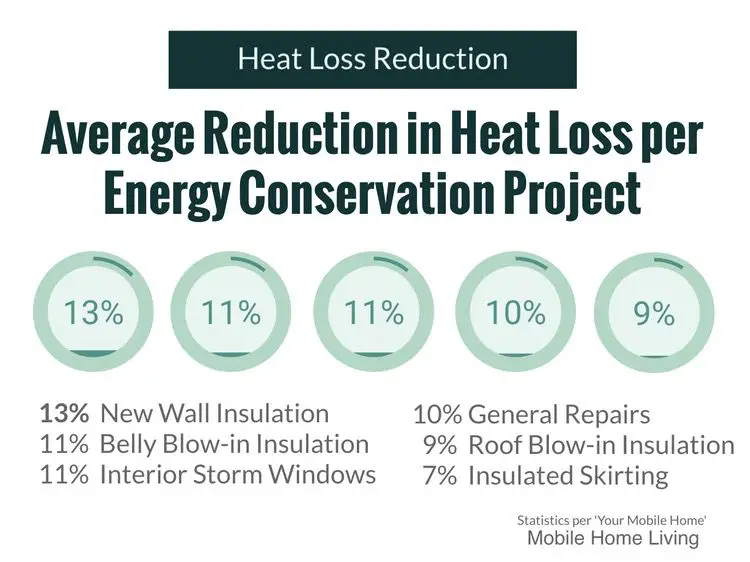

The NREL (National Renewable Energy Laboratory) partnered with the US Department of Energy to conduct experiments on the effectiveness of different weatherization techniques on mobile homes in colder climates. They tested 9 mobile homes in the 1970s and they have recently started another testing program.

The NREL experiments found that the most cost-effective improvements were

- air sealing and duct repair

- furnace tune-ups

- blown roof insulation

- interior storm windows

- blown floor insulation

Notice how it says blown insulation? They tested between blown and fiberglass batt insulation and found that the batts were often damaged during installation and therefore lost effectiveness.

Foam Board

Aside from fiberglass, one of the other most common materials is foam that is made from plastics as opposed to glass fibers.

Foam comes in diverse shapes such as rigid foam board. It can also be sprayed as a liquid that hardens. It can be made from various plastics:

- Molded Expanded Polystyrene (MEPS)

- Expanded Polystyrene (EPS)

- Extruded Polystyrene (XPS)

- Polyurethane Sprayed

- Foamed-in-place Polyurethane Insulation

Advantages: Foam boards offer a high insulating value relative to their thickness (as opposed to fiberglass, which is more voluminous). And spray-in foam is an excellent solution for awkwardly-shaped or difficult-to-reach areas. It also reduces the chances for mold, moisture, dust, and pollen.

Disadvantages: Generally, it’s more expensive than fiberglass structures. Also, it takes longer to install and can’t always be installed as part of a DIY project since you may need specialized equipment.

Cellulose: Recycled Paper Insulation for Mobile Homes

Cellulose fibers can take the place of fiberglass fibers in insulation materials. Instead of glass, cellulose is made out of recycled paper that is concentrated down and then formed into fibers. Some other natural materials you might see for insulation include:

- Cotton

- Wool

- Straw

- Hemp

Advantages: Cellulose is an environmentally-friendly option since it’s produced from recycled materials. Unlike fiberglass, it doesn’t bear the risk of causing lung damage.

Disadvantages: It has to be replaced every five years in many cases, especially if it absorbs water. Unlike fiberglass, it often requires a professional to install it.

What Kind of Insulation and Installation is Best for Each Section of a Mobile Home?

A lot goes into choosing the type of insulation you’ll need for your mobile home. First, you need to decide which kind of material is right for your home. Second, you’ll need to chose the kind of installation that is best for each area of your home.

Once those two decisions are made you’ll need to hire an insulation installer or prepare yourself for an intensive DIY project. Depending on your material, you may need a contractor with specialized equipment or rent/buy your own.

We’ll take a quick look at how this could look in different sections of your mobile home.

Mobile Home Floors and Belly

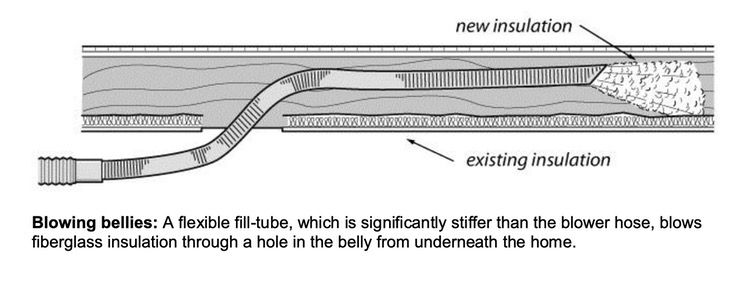

When we talk about a mobile home “belly,” we’re basically talking about the area under the floor system of the mobile home. You have a couple of options for adding insulation to this area but the preferred is to blow it.

If you have complete access to the underside of your mobile home because your belly wrap is missing or damaged and needs to be replaced anyway you may consider fiberglass batts/rolls or foam board. Batts and rolled insulation can easily fit between mobile home floor joists but both require a ton of cuts. These cuts and the complex installation can damage the insulation which will reduce its efficiency.

Foam board would require as much cutting as the rolls and batts but it may be easier to handle because it’s rigid. You can install foam insulation board yourself. We already published an article about installing foam board insulation to your mobile home belly.

If you don’t have complete access to the belly of your home you’ll likely want to use a blower to spray insulation.

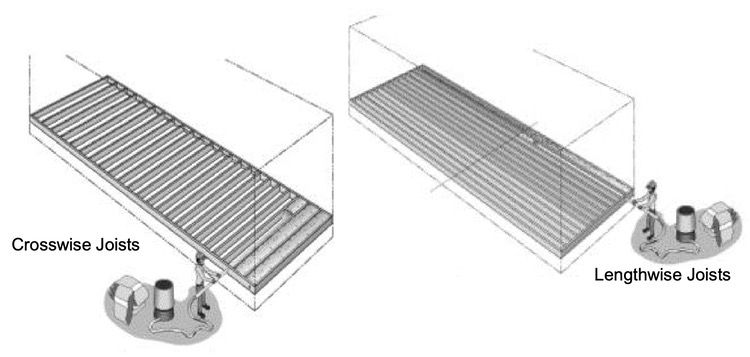

The floor cavities in mobile homes usually have a ‘blanket’ attached to the bottom of the 2″x6″ floor joists that we call a belly wrap. If your mobile home has transverse floor joists (see the image below, traverse joists follow the width of the home) the position of the ducting may create a dropped belly that causes problems if you are trying to blow insulation into the space. Therefore, it needs to have the belly attached to the joists properly to create smaller channels that will require less insulation.

Average insulation densities for loose fill insulation installed in mobile home bellies will be 1.25 to 1.75 pounds of blown fiberglass per cubic foot.- Green Energy Plus

Rim Joist and Wing

The rim joist and wing can also be used to get insulation into the belly of your mobile home. As with the other methods, blowing insulation into a rim joist requires drilling holes. However, if the rim joists is a foundational component it cannot be modified so that knocks it out for many homeowners.

Mobile Home Siding and Walls

Mobile homes made pre-1976 have very thin sidewalls with poor insulation.

Insulation in batts or rolls can be cut and sized to fit inside the walls of your mobile home in the ‘stuff it‘ or stuffing technique. This is a good way to go if you are remodeling the home and will be removing walls and ceilings.

To do the stuff-it technique you will

Blowing Insulation into Mobile Home Siding

Older mobile homes with vertical metal siding will do well with the sidewall stuffing technique. The metal siding is installed with screws attached to a horizontal belt rail. To get to the spaces between each stud you’ll need to remove the bottom row of screws to give the blower pipe access.

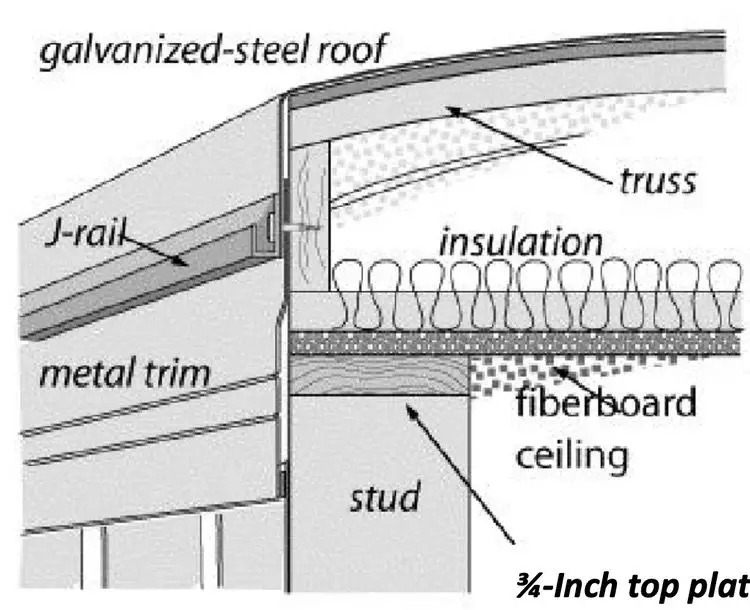

Blowing Insulation into Mobile Home Ceilings

The foam spray/injection method can be used to fill small cavities and prevent conduction and convection. The only issue with the spray/injection method is that you may need special equipment or a contractor.

If you don’t have easy access to the ceiling or roof of your home, and most don’t unless they are in the middle of a remodel, you will need to blow insulation into the space.

Drill and Plug Method

There are two main ways of blowing insulation into the attic or ceiling and roof of a mobile home. The most common is the drill and plug method through the ceiling.

Watch this great video showing how to blow insulation into the attic (ceiling or roof) of a mobile home:

Exterior Attic Insulation Installation: Lifting the Lid or Drill and Plug Methods

You can also blow insulation into the attic of a mobile home through the exterior. How you go about doing it depends on the age and construction of the home. For older mobile homes, you can probably just lift a small section of the roof or you can use a drill and plug process.

Though we love the idea of DIY projects, for ceilings and roofs, you probably need to hire an experienced contractor. Blowing insulation into ceilings requires an insulation blower and it often costs justs as much to rent one as it does to hire it out.

The insulation blower is used to fill each truss bay with insulation. The roof space can be accessed from either inside the mobile home (called interior blows) or by “lifting the lid” or drilling holes and blowing insulation into the space.

For bowstring trusses, you likely have only 1-2 inches of insulation around the edge but 10″ in the center of the home. Over time that insulation can become wet or damaged in a number of ways. Lightweight sloped-roof trusses can have around 3 inches of insulation at the edge and possibly up to 2 feet in the middle. In both cases, getting the perimeter insulated is difficult, even for the most experienced.

The installer will need to blow the insulation in a uniform coverage and with a density between 1.25 and 1.75 pounds per cubic foot.

DIY Spray Foam

Spray foam insulation has come a long way since it first hit the market. Previously, you needed specialized blowers and hoses to blow the insulation into a cavity so it was only available to homeowners that could afford to hire a company with the equipment. Now, there are DIY kits available to install insulation in a mobile home but there seems to be a love/hate opinion about these kits.

Ideally, a professional should always be hired when dealing with insulation because there are so many variables that need to be considered. Electrical and plumbing systems complicate insulation installation.

An understanding of air sealing and evaporation is also important before spraying the first inch of foam. Still, spraying foam insulation yourself is a smart mobile home improvement project that can save a ton of money on heating and cooling and make your home more comfortable.

The Rewards of Installing Insulation in a Mobile Home

It’s no secret that older mobile homes, and the more affordable newer models, aren’t insulated very well. Fortunately, installing insulation in a mobile home is fairly easy now. With today’s insulation technology it’s possible to add substantial R-value to your home for a relatively affordable price.

There’s no need to suffer the consequences of poor insulation. By installing insulation in a mobile home, you’ll reap the rewards of a warmer and more comfortable home. Not to mention, you’ll probably save quite a bit on energy costs.

There’s no doubt about it, installing insulation in a mobile home is the absolute best improvement you can do for your home, especially if your home is older.

It’s our goal to provide the most helpful information so please don’t hesitate to check out more tips on our website. If you’re interested in learning more, please feel free to contact us with any questions — or tips of your own. There aren’t enough resources for mobile homeowners and we aim to change that.

As always, thank you for reading Mobile Home Living!