Mobile home skirting is far more important than most homeowners realize. While it certainly adds curb appeal and can change the look of your home , it also acts as a strong barrier that protects your home and plays a vital part in your heating and cooling system.

Skirting helps retain heat under your mobile home in the winter. That blanket of warm air can prevent your water pipes from freezing.

In the summer, properly vented mobile home skirting regulates airflow under your home which can prevent mold and mildew growth.

In this complete mobile home skirting guide, we will cover skirting materials, costs, ventilation requirements, installation, and more. You’ll be ready to buy and install new mobile home skirting in no time!

How to Measure Your Mobile Home for Skirting

Before you can compare skirting prices and choose which material will fit your needs best, you’ll want to calculate how much skirting you’ll need.

Step 1: Measure your Mobile Home’s Perimeter

Measuring the perimeter of a mobile home is simple.

The perimeter of a home is found by adding all of its sides together. For example, let’s say a single wide is 16 feet wide and 72 feet long so I would add:

72 + 72 + 16 + 16 + 12 + 12 = 200 feet

Note: Do not multiply the width of your home by its length. Multiplying gives you the square footage of a home. We need the perimeter footage.

Step 2: Calculating the Average Height

After you calculate the perimeter footage of your home you’ll need to find its average height.

To calculate the average height of your mobile home, you will need to measure the distance between the ground and the bottom of your home in 6 places: all 4 corners and then at the center point of your home on both the front and the back.

After measuring all 6 places you’ll add them all together and then divide the total by 6.

Popular Mobile Home Skirting Options

There are several different kinds of materials that can be used for mobile home skirting.

Brick, stucco, tin (metal), cinder block, T1011, plywood, hardy board, faux rock, and vinyl are just a few.

You can use just about any material but the following are the most popular.

Vinyl Skirting

The Most Popular Option for Mobile Home Skirting

Vinyl skirting is the most popular choice for mobile home owners for a few reasons: it is easy to install, affordable, and attractive.

Plus, vinyl is very environmentally friendly and one of the most sustainable materials on earth. Vinyl is made from common salt and ethylene from natural gas.

According to Building for Environmental and Economic Sustainability (BEES) software, vinyl siding outperforms brick, stucco, and wood on how it affects the environment based on a combination of environmental criteria.

Advantages and Disadvantages of Vinyl Siding

Unfortunately, the vinyl siding on many of the affordable manufactured home models is not the best quality. It’s usually a thin weak product that is made from recycling old vinyl building blocks. This vinyl isn’t as energy efficient as other vinyl, specially insulated vinyl. If you have this thinner vinyl you should consider upgrading it as soon as possible.

Vinyl skirting does not do well with weed eaters and budget brands do not age well.

Cost of Vinyl Skirting

Most vinyl skirting kits run about $600 and up for a common-sized single wide and will include all the pieces you need to completely skirt the entire home.Thicker, sturdier vinyl will cost more.

Buying a Complete Vinyl Skirting Kit

There are 4 basic pieces needed for vinyl skirting: the panels, the U-channel ground tracks, the top J-channel, and the trim.

12 Foot Panels

The panel itself is usually sold in 12-foot lengths. This is to make it easy for homes that are sitting on an incline, you simply cut the panels at the right dimension you need for the area. You can start at 2′ on one side and end up with 12″ on the other. You’ll need to use the average height method to order the correct amount of skirting.

Ground Track – U Channel

The ground track is bolted into the ground with long rods. It is a U-shaped channel and the panel will fit down into it and keep it secured.

Top Frame – J Channel

The top back is what goes on the bottom of the home before the panels are set into place. It has a top J channel that the top front piece will fit into.

Trim

The top front piece is the horizontal strip in front of the panel. It gives the entire system a more polished appearance and allows the skirting more security. It’s the last part you add. There are V-guards you can add around the bottom edge of thinner skirting to keep the weed eaters from eating it.

See the process of installing vinyl skirting on a mobile home here.

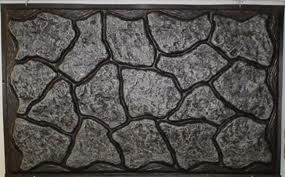

Novik and Brick Panels

Novik is a popular skirting material for mobile homes. But it can be expensive.

Novak skirting requires metal framing and some brands will require professional installation to honor their warranty.

Most faux panels are made from polyurethane and come in pieces that are 46 ¼” wide × 24″ high × 1 ¼” thick.

They look remarkably like real stone. You can frame the area to be skirted with metal 2×2 or 2×4′s and then screw the panels into the frame.

They are light but sturdy, and they can withstand temperature fluctuations very well.

They are a bit expensive but cheaper than real stone and much easier to install. MHPS has Novik panels that are48″ x 18 1/2″ for $21.98. Corner pieces run about $15 each. See installation steps for Novik here.

Reil Rock

The second most popular skirting option is the Reil Rock panels (aka Mason’s Rock). They are made of sturdy plastic, have the look of stone and come in 3 colors.

Reil rock comes in 5-foot sections with 3 height options: 2’6″, 3′ and 4′.

The sturdier construction of Riel rock panels makes them fairly easy to install and similar to installing vinyl skirting with U-channels (or J-channels).

There is a track you can put over the top of the panel, but it’s not needed. If your panel is just shy a couple of inches you can use the top track to cover the issue.

A 5-foot section costs about $32 at MHPS. While it’s more expensive than vinyl it’s sturdier and can handle a bit more.

To calculate for Reil Rock, simply convert your linear foot to inches by dividing by 12. Then use your average height calculation to get the correct panel height to buy. There is a lip on these panels that are about 2-3″ so keep that in mind. If your mobile home sits high above ground you may want to go with a skirting that looks more cohesive – those seams are noticeable (at least they are to me)

Learn exactly how to install Reil rock skirting here.

Concrete, Brick, and Cinder Block

If you want absolute permanence concrete, brick, or cinder block is probably your best choice.

Adding brick or cinder block to a home is a labor-intensive ordeal, but the advantages are worth it. Being practically indestructible is the best advantage.

Concrete panels are easier to install but have similar indestructibility and longevity as brick and cinder block. There are companies that specialize in concrete skirting but you can purchase precast concrete panels, too.

These nearly indestructible skirting materials will almost certainly increase the value of your home. “Homes that have been maintained well and have smart upgrades like skirting and insulation typically sell at a higher price,” comments Ruban Selvanayagam of UK real estate company Property Solvers.

There’s a little misunderstanding surrounding cinder block and brick skirting and ‘permanent foundations’ for mobile and manufactured homes.

FHA loans require that all manufactured homes be permanently installed but a permanent installation involves more than just the skirting material.

A manufactured home can be permanently installed and have vinyl skirting.

Metal Skirting

I’ve always liked the look of a simple metal skirt under a mobile home. There’s a few different types of metal that can be used for mobile home skirting but tin is usually the most affordable.

If you go with metal skirting you may want to consider installing insulation along with it. Metal has a lot of great qualities but it lacks in insulating benefits.

Simple installation is an added advantage. Metal is sturdy on its own so a simple 2″x4″ frame will do (be sure to keep the wood off the ground).

You could just attach the top of the panel to your home and just let the bottom of the metal panel sit in a channel in the ground.

These days the designs for metal mobile home skirting are getting more attractive, too. The old cinder block or large brick stamped pattern has been the most popular design but with a little research, you can find new patterns.

Metal mobile home skirting has 2 great qualities: it can be painted any color you want and can withstand a weed eater.

The price for metal skirting is around $10-15 per 5-foot panel.

Foam Insulated Skirting

Insulated mobile home skirting has made headlines lately but it may not be the best place to spend your money. The NREL tested mobile home energy conservation techniques and found that installing new insulated skirting to a mobile home increased 7% while blowing insulation under the home increased it by 11%. Adding wall insulation increased efficiency best, at 13%.

Therefore, you may be better off spending the money on insulating the floor of the home, not the skirting.

Foam skirting can be used along with frame but some brands won’t need a frame at all.

You can get complete framing solutions to place the panels. the

The price of panels is approximately $10-15 per foot.

The installation kits depend on the linear foot needed.

You can learn about the installation process of insulated skirting here.

Plywood, OSB, and T-111 Skirting

Wood has always been a well-known construction material. Using wood for skirting isn’t the best option unless it’s treated and your property isn’t overly wet. Wood is susceptible to rot and insects and soaks water up quickly.

Hardiboard and OSB are very sturdy. OSB is cut with the tree’s grain and engineered to make a very strong product.

Wood products that are not waterproof are going to get swelling from moisture. The price depends on what you chose and installation can be simple or complicated. Some people suggest that you use a sealer and caulk the ends of the boards before putting them up just as an added precaution against moisture. You can use planks and get the look of siding, too. Lots of potential with wood!

Other Skirting Options

The sky is the limit when it comes to skirting materials for mobile homes. Of course, the materials listed above are probably your best bet you can save money by thinking out of the box. Perhaps you could reuse material or keep construction scraps out of the landfill. For example, a damaged metal roof panel could become a nice access panel for your skirting.

Old barn tin has already stood the test of time and it’s gorgeous. One of our featured homes has antique barn tin as a skirting, and it is gorgeous! Railroad ties and straw are two unique mobile home siding options we’ve seen.

Really, you could use just about anything that is weather-resistant and rigid. Keep flame retardancy in mind before you decide to use a unique material.

Regardless the Material, Venting is Vital

It doesn’t matter which mobile home skirting material you choose, they all require properly placed venting to control the airflow under your home.

Vent Ratio

Vents in mobile homes are so important that many states regulate them. Most experts agree that you need around 1 foot of venting for every 150 -250 square footage in a mobile home.

Vent Placement

You’ll want to be careful where you place the vents in your skirting. You don’t want a vent near the plumbing pipes. However, you do want a vent within 3′ of each corner. T\air can circulate efficiently and you don’t get dead air pockets in the corners.

Vapor Barriers

The ground vapor barrier is a thick plastic sheeting that lies on the ground under your mobile home. It does exactly what it says it does, creates a barrier that protects your home from ground moisture.

If you have a healthy ground barrier, you may be able to get away with less venting. John Krigger, the author of Your Mobile Home, wrote that you may only need 1 vent for every 300 square feet if you have a ground vapor barrier.

Smart Tip: Extending the vapor barrier about 6″ past the perimeter of your home is a smart move for a couple of reasons. You can use the skirting’s ground frame (or C channel if you’re installing vinyl) as a staple of sorts that can secure the vapor barrier to the ground. And, secondly, ground vapor barriers help keep weeds and grass from growing close to your home which can certainly reduce the chance of damaging your beautiful new skirting.

Conclusion

Mobile home skirting is vital to a healthy home. In fact, it’s mandatory in many areas of the nation. New skirting can completely change the look of your home and save on heating and cooling costs for years.

Thanks so much for reading Mobile Home Living!

Photo Sources: Faux Panels, Reil Rock

Canada has CSA codes to follow for skirting Z240 and A277.

Who sells this product in Fredericton New Brunswick

I have cinder block skirts. Recently a few sections have cracked and one big section has fallen under my home.

I have done temporary repairs until I can get someone to look at it.

I am interested to know how/why this is happening.

Hi Terri,

Your local mobile home supply store should be the best place. You can also find some profiles of metal through Lowe’s or Home Depot via special order. Best of luck!

Where to buy metal siding

Hi Vicki,

I’d say just digging yourself out and then building a stronger frame behind the skirting would work. You could use pressure-treated 2x4s or go with the more expensive metal studs they use for framing now. If you could cement that frame into the ground a bit it would probably hold for many years. I wouldn’t attach the skirting to the home for strength so there’s no chance of damage, I’d put all the strength from the ground up.

Best of luck!

Hi Tina,

I’m not sure what type of skirting you have so I can’t be very helpful. However, all skirting should have an access door and vents that open and close (open for summer, closed for winter). If your skirting doesn’t have vents you must get some (otherwise you home wont have any air circulation under it and mold and mildew loves dark damp places with no air circulation). The formula is 1 square foot of vent per every 150 square foot of floor space.

Also, an access door is needed for quick repairs. Otherwise repairmen will damage the expensive skirting to get under the home and it may not be easy to fix.

Best of luck!

I had the winterized skirting put on my mobile home this summer. The skirting that was on it before was damaged but I could easily remove a panel here and there to get under the mobile home. I am hoping that this will prevent freezing of my pipes because last winter I had several. My question is if my pipes should freeze even with this winterize skirting how do I get under the mobile home so they can be repaired I can’t figure out how to take off the skirting. Please advise thank you

I bought an older double-wide that was pit set and back-filled. The skirting was not supported correctly and my landscaping is now sliding under my home. What is the most economical way to rectify this situation?

Hi Natasha! Metal is the better choice for skirting, especially if you need a bottom track. I’ve seen them pieces you’re referring to as skirt tracking, metal trim, or just metal framing. Many skirting manufacturers have their own framing and trim kits so you may be able to just buy a trim kit from a skirting company and then just create your own panels. Best of luck!

Hi,

Great article! In my area (Ontario, Canada) I’ve seen a few trailers framed with wood, insulation placed in-between the wood, and then some sort of cover (like the ones you mentioned above) placed over top. I would rather use some sort of metal framing rather than wood as it would rot etc. What would the metal pieces be called? What kind of metal would be used to make the frame?

Thanks for your help!

BILLY BO BOB;

With no ill will or impoliteness intended Bob, the article DOES have a unique section and mention of ventilation, and the exact same formula for figuring how much venting per sq foot of floor space that is needed. recheck the article, there under:

Mobile Home Skirting Tips and Expert Advice

Tip #1: Venting is Vital for a Healthy Mobile Home

and just underneath that is the formula for one foot per etc….

Good to note but he was on top of things.

Glad you liked it, David!

Your publication is very useful,interesting and helpful, especially to a first time manufactured home buyer. Thank You for this valuable resource.

Hi Harry,

It sounds like it will be a wonderful design! I would use screws on the top bracing, and on the bottom, you may want to look into a metal channel so you can have a little less give between the vertical braces. I’d maybe seal the panels on the bottom just as an extra layer of protection from rot and ants.

I’d love to see photos! Best of luck!

Hi Trig,

We don’t sell anything, we just share a few places that we find online and appear to treat customers well. We are an affiliate of a mobile home supply store (but I’ve never even spoken to them personally, I just ordered a book from them and it was shipped fast and in good condition, so that’s really all the association I have with them).

I would call your local mobile home supply store and see what their prices are before you order. Shopping online can be cheaper but in most cases, the shipping charge will get you. Plus, returns and damages can be huge issues when buying online). If you don’t buy from your local retailer you can usually get a recommendation of installers.

Best of luck!

Good point on the contractors. So where would you recommend I find labor to install the skirting that I am considering buying from you? I am in New River, about 30 N of Phoenix.

Hi Billy,

You are absolutely right. We do go over the formula in the article titled 6 Mobile Home Maintenance Tips Every Owner Should Know but it really does need to be linked to more clearly and quoted to ensure that owners understand the dead air pockets in the corner and the ratio. Thanks for catching that!

One thing your article does not explain is that there is a standard (through HUD) regarding ventilation of a Manufactured Home! Regardless whether it’s vinyl, wood, brick or foam core insulation, it must be vented properly.

§ 3285.505 Crawlspace ventilation.

(a) A crawlspace with skirting must be provided with ventilation openings. The minimum net area of ventilation openings must not be less than one square foot (ft.2) for every 150 square feet (ft.2) of the home’s floor area. The total area of ventilation openings may be reduced to one square foot (ft.2) for every 1,500 square feet (ft.2) of the home’s floor area, where a uniform 6–mil polyethylene sheet material or other acceptable vapor retarder is installed, according to § 3285.204, on the ground surface beneath the entire floor area of the home. (b) Ventilation openings must be placed as high as practicable above the ground. (c) Ventilation openings must be located on at least two opposite sides to provide cross-ventilation. (d) Ventilation openings must be covered for their full height and width with a perforated corrosion and weather-resistant covering that is designed to prevent the entry of rodents. In areas subject to freezing, the coverings for the ventilation openings must also be of the adjustable type, permitting them to be in the open or closed position, depending on the climatic conditions. (e) Access opening(s) not less than 18 inches in width and 24 inches in height and not less than three square feet (ft.2) in area must be provided and must be located so that any utility connections located under the home are accessible. (f) Dryer vents and combustion air inlets must pass through the skirting to the outside. Any surface water runoff from the furnace, air conditioning, or water heater drains must be directed away from under the home or collected by other methods identified in § 3285.203.

Hi Tom,

You can use just about anything as long as it is framed well. In WV, we use old metal a lot for underpinning. The majority of the time, the frame was made of 1×1″ or 1×2″ with a vertical stud at every seam. I don’t recall how they handled the ground connection though I would say if the material is sturdy enough you wouldn’t need much.

Best of luck! I would love to see some pics of your process – it may help other homeowners to share your project. Thanks!

This is my first time dealing with underpinning a mobile home, Can you use corrugated roofing for underpinning skirting? how do you frame to do that?

Hi I am looking put skirting on the bottom of my new modular home I have come up with a design to use 8 1/4″ Hardy plank siding in the vertical position 32″ high with 2″ bat ripped from hardy plank to cover the space between each board. I plan on making 2x4x8′ treated panels with a 2×4 flat with a piece of 1/2″ treated plywood on each corner 1″ square and a 2×4 running diagonal from the top corner to he bottom corner for bracing. I plan to caulk and paint each panel as I put them down. Do you think this will work? Also what kind of nails should I use I have a framing nailer that can go up to a 3″ nail.

The top front piece of vinyl trim is not there merely for appearances. It’s there to hold the top of the skirting in place. Too many people think they’re supposed to screw their skirting to their homes before snapping on the top piece. No, no, no! Your skirting will buckle if you do that. Instead, allow the skirting to “float” between the front and back pieces.

Visit any mobile home park, and you’ll likely see lots of buckled vinyl skirting. Unfortunately, too many contractors are low-paid individuals with minimal training. They don’t know how to install skirting correctly. So do yourself a favor, and hire a contractor who actually knows what s/he’s doing!

Hi Henry,

I do not but that sounds like a decent idea. I’d be worried about the R-Value in areas with rough winters – the sunshine would help a lot but the thermal loss would likely neutralize it. I know you can go to Lowe’s and have the clear acrylic sheets cut to any size. You can use a sander to make it less translucent.

Best of luck! let me know how it goes!

I’ve been advised to consider replacing a few panels of our vinyl skirting with translucent panels to make the crawlspace less attractive to dark-loving pests like packrats and squirrels. I’ve been unable to locate a source. Do you know of one?

Hi Alana,

I found this: If the perimeter enclosure is non-load-bearing skirting comprised of lightweight material, the entire surface area of the skirting must be permanently attached to backing made of concrete, masonry, treated wood or a product with similar strength and durability.

The link below will take you to the HUD’s Housing Handbooks page. You’ll want to download the 4000.1 books for FHA Single Family Housing Policy Handbook (there are two). https://portal.hud.gov/hudportal/HUD?src=/program_offices/administration/hudclips/handbooks/hsgh

Best of luck!

We are refinancing our home with a FHA loan. We are going to replace our vinyl skirting with hardie board. Do you know how we should install it to meet FHA guidelines?

Hi, Dee!

Try Mobile Home Part’s Store at http://mobilehomepartsstore.com/category/SKP.html

And here’s a 10% off coupon code I received in my email the other day: Coupon Code: MHM2310

(Disclosure: I am an affiliate for them but I don’t know how to create a link so this is not an affiliate link).

They have a lot of good information on skirting but I haven’t had a chance to compare prices recently. They usually have the best prices but the shipping can get expensive on some items.

Hope that helps!

I was on a site recently and forgot to save it. It was a company that sold complete skirting kits for mobile homes. It included everything. Would you know of this site. I have searched and searched and cannot find it.

Hi Tim,

This is typical for areas with freezing weather, that’s why we only fasten the skirting panels to the tracking on the ground and not to the top trim. The panels are to stay loose on the top so it can move when the ground freezes and thaws. That trim piece on the top of the skirting (bottom of the home) is supposed to hold the panels in securely while still allowing the contraction in the cold and each panel should overlap the next by 2″ . The following PDF is the most informative skirting information I have came across online: http://www.jfw-melas.net/downloads/skirt-20.pdf

Hope that helps! Best of luck!

Hi. I live in a cold weather state and have problems with ground freeze that pushes up my skirting so much that it bends or pops out. Is there a different Front Cap Trim for Skirting wider than 4 inches that would allow the skirting to rise and fall. I have trimmed the panels as short that I can but they still bow very badly in extreme cold. I plan on replacing all my skirting this summer and would like to eliminate this problem every winter. Any help would be appreciated. Thank you.

Tim

Hi Dimple,

Laws regarding parks completely depend on the state, county, and contract signed by the tenant. Sorry I can’t be more help.

Is it illegal for a mobil home park to force a tenant to take out the skirting if the mobil home belongs to the tenant and the tenant want to sell?

Hi Karen,

Typically, you would use a frame built from 2×2’s or 2×4’s (or even metal) to attach skirting to the home. Wood is usually cheaper and easier to work with. Creating a frame for your skirting is the same concept as building a wall, you create a frame to attach the Sheetrock and create structural strength. Some skirting, like vinyl, is bought as a complete system with their own framing but it doesn’t hurt to reinforce it, especially in high wind areas. Here’s a few images that may help: http://www.dmaskirting.com/index_files/metalmobilehomeskirtinginstallationinstructions.htm

Unfortunately, even the best frame wouldn’t be able to withstand a strong hurricane.

There are a couple of different options available for hurricane window protection. There’s rolling shutters, colonial, panels, accordion, sliding, and the propped up Bahama shutters. There’s even a new fabric. Google hurricane shutters or storm shutters and you’ll find all the options. Here’s an article I found that may help: http://www.sun-sentinel.com/local/broward/sfl-hc-shutterguide-htmlstory.html

Here’s our mobile home skirting guide: https://mobilehomeliving.org/mobile-home-skirting/

Best of luck!

How would you protect or anchor down your decorative skirting during a hurricane? We live on the coast and hurricanes are not unusual. I just wanted to see if anyone knows of how it could be done. Also does anyone know of plans for shutters that can be closed during a storm?

Hi Ben!

We skirted our home in tin that we bought from Lowe’s. They had the sheets stamped like brick but we went with the flat design. You may be able to get a better deal at a locally-owned mobile home supplier. Try Google searching your town with the words ‘buy tin sheets’ (or sheet metal if that’s what you prefer – tin should be a lot cheaper though).

Thanks so much!

HELLO MY NAME IS BEN AND I WOOD LIKE TO FIND OUT

WHO SALES THE STAMPED METAL SHEETS THAT LOOK LIKE

ROCK OR CINDER BLOCKS, I NEED SOME THING LESS

EXSPENSIVE I HAVE FIVE OF THESE 16 BY 80 I NEED TO SKIRT

Very nice site. I have a couple rentals looking at hardy Plank for skirting been told can”t go on ground — any ideas for barrier between ground and bottom of plank. I was thinking some plastic on the ground and landscape timbers on the plastic. Figure worse case the timbers can be replaced fairly cheaply if need be. Any thoughts from you or your readers,

Hi Akili!

Here’s a couple of websites that ships anywhere in the US though I haven’t compared prices.

http://mobilehomeadvantage.com/sku.cfm/sub_cat_id/704/ID/183/

http://allhomesupply.com/rigid-foam-insulated-skirting

Here’s a site with more information about the rigid foam boards: http://styro.net/FoundationInsulationPanel.htm

Good luck!

Please let me know where I can find the rigid foam skirting. I live in Lugoff, S.C. and have contacted several local businesses with no luck.

Thanks so much.

Akili

Hi Sharon! I don’t have any photos of ties being used specifically for skirting but here are a few links that show them used in building. It would be a very labor intensive project but if you had the manpower to move them easily it would look great!

Here’s railroad ties being used as a wall structure: http://www.motherearthnews.com/homesteading-and-livestock/building-with-railroad-ties-zmaz71mazsea.aspx

A home built of railroad ties: http://www.geocaching.com/geocache/GC3A1V7_av-historical-poi-railroad-tie-house

The cutest cabin ever with railroad ties path: http://customslipcoversbyshelley.blogspot.com/p/our-cabin.html

Good luck!

Do you have any photos of the rail ties skirting? I’m assuming that the tie would be sliced into 2-3 length pieces. How do the corners work?

Hi Alicia!

I’ll look into brick skirting and get an article written on it as quickly as possible. I’ve never dealt with brick so I’ll need to ask around for some good tips. I’ll get back to you as quickly as possible. Thanks!

I am looking into remodeling my mobile home. I want to add on to the front and give it a house look. I also want to include brick columns on the porch. Want information on how to do brick skirting also. I want a total remodel basically.