Environmentally Friendly Houses – A True Trash to Treasure Tale of a Mobile Home

Manufactured homes have always been a leader in the environmentally friendly building. Factory construction limits delays and allow precise control of inventory and material handling.

Related: Manufactured Homes are Earth Friendly!

While buying a new manufactured home is a great way to reduce your footprint they can’t compare with the green building method that these 2 industrious ladies in the foothills of West Virginia used.

Carrie Stone, JD and Elisia Ross, RN recycled their way to a completely remodeled mobile home and one of the most beautiful environmentally friendly houses I’ve seen. They used an old mobile as a base and then added papercrete, old tires and a lot of hard work to build the home. The results of this green mobile home renovation are amazing and the total cost makes it even more amazing; they spent less than $10,000 and that includes the cost of the land.

It’s a true trash to treasure story!

On their website, BuiltFromTrash.com, they provide the reasoning behind such a drastic build and why they chose to build their own environmentally friendly houses:

“…The planet simply cannot sustain our post-industrial lifestyle…We decided years ago that we could no longer sit by and wait for someone to lead us to a more sustainable promise land. So, instead of sitting on our hands, feeling frustrated and angry, we decided to do something……We hope our story inspires others (you?) to stop waiting and BE that change you want to see in the world. “

Pictured above is the mobile home they started with. Not much to look at, but plenty of potential!

The Green Mobile Home Transformation

The transformation of this mobile home is amazing. They added 2 additions to each side of the mobile home, each 6 ‘ X 55.‘ The additions are supported by ten 4′ X 4′ posts to help provide additional support for the papercrete.

Using papercrete, a very green building material, they were able to keep their new material usage to a bare minimum but still have one of the best modern and stylish environmentally friendly houses ever.

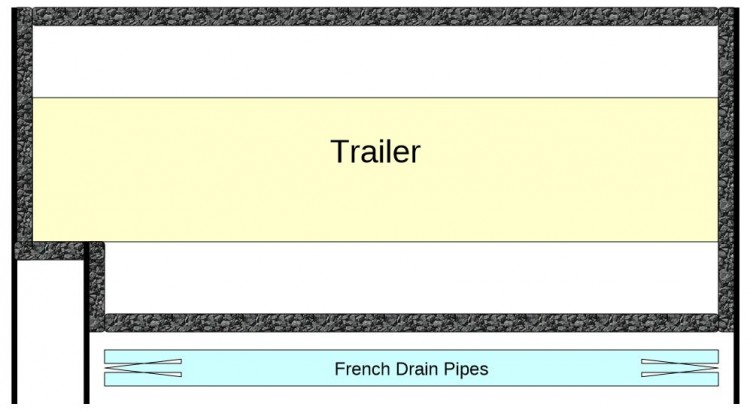

After having the land leveled and proper drainage added, they pulled the leaky mobile home into position and re-roofed it immediately. This protected the home from further water damage and allowed them to live in it while they worked. Here was the original blueprint for the overall design, with the french drain pipe placement and the gravel foundation outlined for the addition walls:

The roofing was first. They needed to secure the original mobile home and get it in shape before they could do anything else. A standard 1 half-pitch roof was installed:

One the roofing was framed up, they began outlining the addition and getting the foundation ready. They used tires filled with papercrete, soil, cement, and sand as the base:

After some testing, they figured out that if the cut the top lip of the tires off, as shown below, it made filling the tires with easier.

Pictured below are the finished roof and the beginning of the first wall for the addition.

Used tires filled with soil, papercrete, and Portland cement were installed to act as both a retaining wall and the foundation. The construction material alone is one of the best examples of building all types of environmentally friendly houses – but the fact they also used an older mobile home proves they were serious about doing their part to help our earth. Once set, framing timbers were set into the tires. The pillars acted as the load bearers and gave them a strong frame in which to pour the 12″ thick papercrete walls around.

Papercrete has many qualities as a building material. It is mold, bug and rodent resistant, a natural flame retardant and makes a great sound-proofing material. It traps millions of tiny air pockets and makes for a great insulator. The R-value, or thermal resistance, is reported to be between 2.0 and 3.0 per inch and the walls are typically 10 to 12 inches thick. Energy Star recommends an R-value between 38-49 for West Virginia so this home comes close to the recommendation.

Additional framing was needed because papercrete is not normally recommended for use as a load bearing material. The compressed strength of papercrete is only 140-260 psi compared to regular concrete that registers at 2200-10,000psi. Still, the mold and fire resistance, soundproofing and insulation values make papercrete perfect for building walls.

Wikipedia best describes papercrete:

Papercrete is a construction material which consists of re-pulped paper fiber with Portland cement or clay and/or other soil added. Papercrete gets its name from the fact that most formulas use a mixture of water and cement with cellulose fiber……The fiber is usually acquired from recycled newspaper, lottery tickets and phone books. The mixture has the appearance and texture of oatmeal and is poured into forms and dried in the sun, much like the process for making adobe.

Since WV soil is mostly clay based the women had to test different ratios to achieve the best consistency for the build. The following recipe is what worked best for them:

Carrie and Elisia’s Papercrete Recipe

- 5 parts drained paper mulch

- 5 parts sifted clay

- 1 shake of Borax

- 5 parts Portland cement

Making papercrete is a very labor and machine intensive process. A highly customized process was required for the vast amount of papercrete they needed to form the exterior walls. They found enough paper through local resources such as newspapers and libraries. It’s not easy building environmentally friendly houses, but the overall good for the earth overshadows the immense labor required.

Once the foundation, roof and framing was intact, they began building the forms for the walls. At 12″ thick, each layer of papercrete would need to be poured and allowed to dry. After drying, the form was removed and set above the newly dried papercrete. After that, another layer could be poured on top of it. That process was repeated over and over again.

Below you can see the papercrete walls being poured onto the concrete forms placed on top of the tires:

Once the walls were completed they were able to finish the roofing and decking.

Lots of planning goes into any home, but especially when building environmentally friendly houses. However, the results are more than worth it. While this probably couldn’t be done where stringent building codes are enforced, this is a great way to build an affordable home that is environmentally friendly in every way.

The Interior

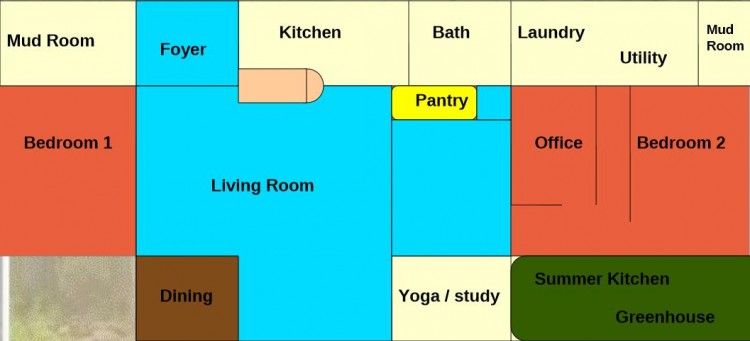

While all the exterior building process was going on there was plenty of interior modifications happening as well. Below you can see the layout of the home after the renovation. Click on the circles to see the original mobile home layout.

The interior after the total home renovation:

Environmentally friendly houses are a great way to construct a home if you are serious about saving the earth one home at a time. Every little bit helps. Every older mobile home that is kept out of a landfill makes a difference. These ladies determination is a perfect example of the possibilities that mobile homes, even those bound for the landfill, have. Carrie and Elisia are true environmentalists that took matters into their own hands and proved that a home can be beautiful, affordable and green.

Please check out their website, BuiltFromTrash.com. You’ll see many more photos and get lots more in-depth information there.

As always, thank you for reading Mobile Home Living!

All images property of BuiltFromTrash.com.

This has become an inspiration. I’m currently finishing the interior of a 1965 Lamplighter. Your blog has shown me there is hope no matter how many people say the project is useless

Hi I liked your remodel. I own a similar mobile home and wanted make the roof like yours but am curious to know if you have any suggestions since am afraid of the added weigh it will put in the walls by doing the roof with 2×4.

This is a very good tip especially to those new

to the blogosphere. Simple but very precise

information… Thanks for sharing this one. A must read post!

Hi Art!

Thank you so much for the kind words! I am very committed to advocating for manufactured homes and I’m so happy I have the opportunity to do it on a broad scale like this. I will admit to slacking a bit here lately (summer time and a 1965 Airstream Safari seems to take up all my time and energy these days…lol).

Hope to hear from you again!

This is utterly fantastic! combines my love for “earth ships” and tiny houses. However, I don’t see how they could have possibly done this all (including land) for under $10,000! I will have to get deeper into their blog to find out. Sourcing affordable materials must have taken a very long time.

Thank you for sharing. The prospect of buying a single wide on land has come to me and I immediately set out to find a blog like this. I had no idea it was it’s own movement, on par with remodeling vintage travel trailers.. Makes me look at the opportunity in a whole new light. I have also noticed how in depth your responses can be to comments and what a dedicated blogger you seem to be. I will definitely be using this site for inspiration!

Thank you so much Karen! I’m so glad you like it!

This is so interesting. I love their finished product. It truly is amazing. What a great thing to do with an older trailer. Thank you for adding it to your site. I never would have found it or known anything about papercrete without your article..

I just love your website!!! So much truly helpful and interesting information.

This is a fantastic remodel. Efforts like this prove that you don’t have to be rich to build a great and stylish place to live.

Thank you for reading them! I love to see remodeled mobile homes, I’m just glad others do, too :) Hope you are doing well!

Crystal! This is the most innovative remodel I have seen yet! Thanks so much for finding these gems and sharing them with us. :)