A properly prepared lot is critical for a long-lasting healthy manufactured home.

The manufactured home installation process is complex – more so than most people realize. It’s so complex that manufactured home site-prep and land development must be done by professionals that have been trained, licensed, and bonded in most states.

Manufactured Home Sites are Larger than Most Site-Built Home Sites

A little over 60% of new manufactured homes are placed on privately owned land now.

In 1995, the AHS did a study that found the average lot size for manufactured homes was around 0.88 acres, while site-built home lots were only around 0.43 acres. These larger lots can be explained because manufactured homeowners tend to place their homes in more rural areas where land is less populated and more affordable. These rural lots usually have fewer regulations and zoning restrictions.

The national HUD code requires a certification for the actual installation of a manufactured home and a final inspection after the home has been installed. However, it does not regulate the site-prep process directly, the federal government agency leaves it to state and local agencies to oversee that aspect of the installation.

A properly installed manufactured home is imperative.

Most manufactured home complaints are due to improper or incorrect installations and failure to properly maintain the home. An incorrect or sloppy installation.

Many manufactured home-buyers don’t understand just how complex manufactured home site-prep is. Hopefully, this article will help a bit. We’ll be covering the basics of manufactured home site-prep and land development including soil composition, water drainage, and grading.

We’ve covered the basics of manufactured home installation and setup in another article here.

What Does manufactured Home Site-Prep and Land Development Include?

Manufactured home site-prep is a complex process that often requires two or more crews to work together to get the property prepared for the home. Preparing the site for a manufactured home includes many steps, a few of the most important are:

- Soil testing and conditioning to ensure the ground can hold the weight of the home

- Excavation and grading which can include cutting down trees, creating roads or driveways so the transporters have easy access, and grading the ground for proper water drainage

- Foundation and/or pier prep (concrete truck and crew)

- Utility trenching and connection: sewer and septic installation, water well drilling (usually necessary in more rural areas)

Site Prep in Manufactured Home Parks

Homes being placed inside a park or mobile home community will usually have a much easier site preparation process. In most parks, the land is likely already graded level and the lot design makes for easy access for the mobile home movers. In addition, the utilities will usually be ready for connection.

Unfortunately, it’s a much more complicated scenario for private land, especially in areas with mountains, swamps, sand, and water.

Related: Learn how to get your manufactured home site-prep financed with FHA Loans and Other Manufactured Home Financing Options.

Pre-Sale Site Inspection are Important

A well-trained salesperson should always inspect the site before the home buyers place their home order.

This on-site inspection will help the salesperson guide the buyers toward the best floor plan, window, dust extraction system and door placement, and even whole-home location to increase energy efficiency.

An on-site pre-sale property inspection can help the salesperson understand the buyer and their needs better. In addition to understanding lot size restraints, a pre-inspection can bring up future plans and possibilities.

For example, if a manufactured home buyer plans to build a garage beside the home, a window won’t be needed on that wall but a door would be helpful. Buyers can have a manufactured home built to the exact specifications needed for those future additions or home improvements.

Pre-sale site inspections will also give the salesperson an opportunity to educate a buyer about the foundation choices. Site preparation will vary depending on the installation type.

See more manufactured home site-prep information in our Directory of Mobile Home Manuals.

Two Types of Foundations

One of a manufactured home buyer’s most important decisions isn’t which model they go with or what upgrades they chose, it’s which installation method they use.

The two types of installation for manufactured homes are permanent and non-permanent. The installers job is more complex with permanent installations so naturally the cost will be higher.

The site will

Non Permanent Foundations

Around 75% of all manufactured homes are installed on nonpermanent foundations because it is significantly cheaper. A common nonpermanent foundation involves piers of concrete blocks situated on top of a small base of concrete or treated wood and placed under the home’s I-beams.

Permanent Foundations

A permanent foundation is more expensive but there are many advantages.

A manufactured home installed on a permanent foundation may allow the home to be classified as real property. That means a manufactured home may appreciate, or gain value, over time. It also means you can qualify for a traditional mortgage and have access to more government-backed financing options. Homeowner’s insurance will likely be easier to get and at lower rates.

Investing in a permanent foundation for a manufactured home is a large upfront investment but it can more than pay for itself quickly.

Choosing the Right Installers and Site-Prep Contractors

The installer should be hired privately from a pool of candidates that was provided by both the dealer and outside resources.

Home buyers should interview, check references, and receive bids from each candidate before making a choice and signing contracts. Learn how to hire contractors without getting ripped off here.

Buyers do not have to use the contractors and installers that the dealer suggests.

First Site Analysis and Inspection

A site analysis will be the first step in the long process of manufactured home site-prep and land development.

In addition to many other things, installers will need to determine:

- Right-of-way and home transportation needs (overhead and under home clearance)

- Zoning and Land-use restrictions

- Perimeter needs – fencing, roadway modifications, etc.

- Proper placement of the home

- Footing and pier sizing and location

- Soil and ground composition and modification

- Drainage, flood zoning, or water issues

- Permits, surveys, and inspection applications

Installers will plan out how to get the property prepared for the trucks and equipment needed. They will take into account the truck’s turning radius requirements as well as its weight and height allowances.

Securing Permits for Site-Prep

Once the installer creates a complete site-prep and installation plan for the home they will usually begin applying for permits.

In some states, the permit applications will fall on the dealer or buyer themselves, but in general, the installer or general contractor will be handling them.

Several different permits may be required for manufactured home site-prep in some locations. Some of the most common permits include:

- Transport permit for the truck

- Utility lines

- Soil bearing and/or percolation test

- Groundwater height test

- Footings, anchoring, piers

- Sewer, gas, electrical connection and testing

- Porches, steps and stairs, garages

Raw Site Preparation

In many cases, the land that the manufactured home will be placed on land that needs trees cut and the soil

When home buyers are trying to save money they will sometimes

A properly planned and developed site can be the difference between a long lasting healthy home and a home that has future issues.

A tree removal expert in Seattle states it may cost between $100 and $300 to remove trees under 30 feet tall.

Surface Prep

Surface preparation is fairly straightforward. Vegetation and debris are removed and driveways and access ways are scouted.

Installers need a wide range of knowledge, such as horticulture, for a successful mobile home site-prep. Knowing which trees to remove and which to keep is an important part of site-prep.

Large trees can be dangerous and a tree’s drip line and root structures need to be considered.

A healthy balance of shade and sun needs to be maintained around the home and a knowledgeable installer will understand this.

In some areas, installers must look for signs of termites infestation on the site.

Soil Compaction

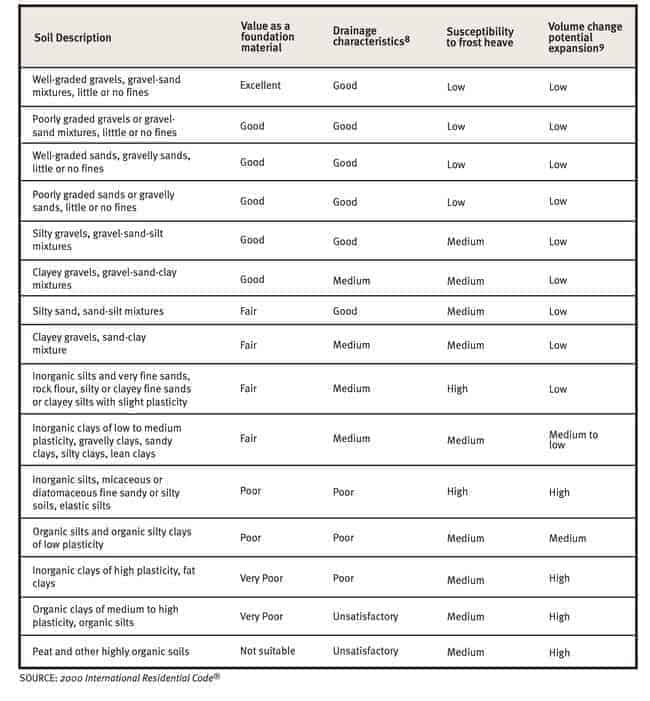

An important step during manufactured home site-prep and land development is soil compaction and composition. Installers must understand the different types of soils to keep movement and instability at a minimum and drainage at a maximum.

The soil is much more important than most manufactured home buyers realize. The home needs soil that can withhold the weight of the home and will not sink or shift over time.

If there is ‘problem soil’ present, a Geotechnical Engineer may need to be called. For example, peat and topsoil are prone to settle so an organic material will be introduced to counteract the problem.

Gravel and stone are often used in connection with soil compaction needs. Gravel and stone that is compacted correctly can act as a solid and will transfer force onto the next surface equally.

Compacted soil doesn’t hold water as much as non-compacted soil so it may be used for drainage issues.

Soil Bearing Tests

Installers will need to do a soil bearing test during manufactured home site-prep to determine is weight-bearing capabilities. A penetrometer is a small tool used to test bearing capacity.

Most code requires that soil must have a bearing capacity of 2,000 pounds per square foot or more.

The installer will use the soil bearing capacity to help determine the size of footings used under the home as well as their placement.

Soil conditions are notated and tested during site-prep. Installers look for ‘adverse site conditions’ such as organic soil, expansive soil (using a shrink-swell test), slope, and subsidence.

Another test the is important for manufactured home installation is the sub-surface probe, it determines the pull-out resistance of the ground anchor.

Water Drainage

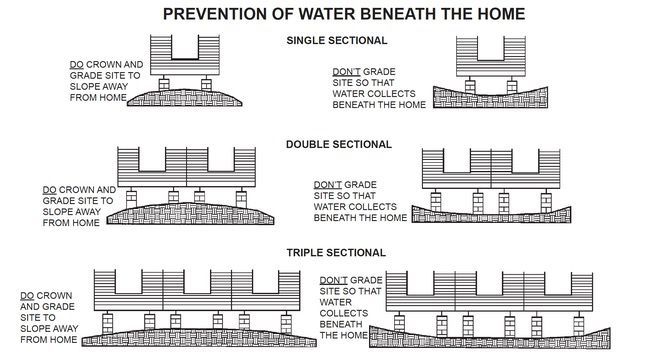

Drainage is even more important than soil in manufactured home site-prep because water must be diverted from the home at all costs. Water takes as much as it gives and will destroy a home quickly.

Water will be coming from all directions and in all forms so creating diversion channels to keep it away or move it away from the home is vital.

Ice, rain, vapor, and snow all need to be considered. Ice can create damage in several ways but ‘lifting’ the foundation via ice

Vapor and condensation can cause moisture issues in and under the home and should be controlled.

The two most popular ways to dispose of the water is to let it soak into the soil at a controlled rate or pushing it off the site using gravity (though sump pumps work as well).

Crowning or creating a small mound will keep water from pooling under a manufactured home. The image below shows the right and wrong methods to prevent water from pooling under a manufactured home. (Source: Skyline Home’s Installation Manual)

Surface Drainage

Surface drainage is the same concept as guttering and an extension of it, just on a larger scale.

Common forms of diversions are ditches, dry wells, pipe systems, and drains.

Water from a hill above, a pond beside, or the water table below must also be considered and drained away from a home.

The most common surface drainage and water diversion system is the simple gutter and downspout system on a home. These systems collect water falling on the home’s roof with gutters. From there, gravity and slope push the water into the downspouts and washes it away from the home.

Another form of surface drainage is sloping or grading the land to divert water away from the home.

Grade and Slope

Grading the land into a slight slope is a common method used to keep water away from a manufactured home.

The grade around the home must be enough that gravity can move the water away from the home. HUD wants to see a 5-6” slope around the first 10 feet around the home. That equals out to a mere ½” for every foot.

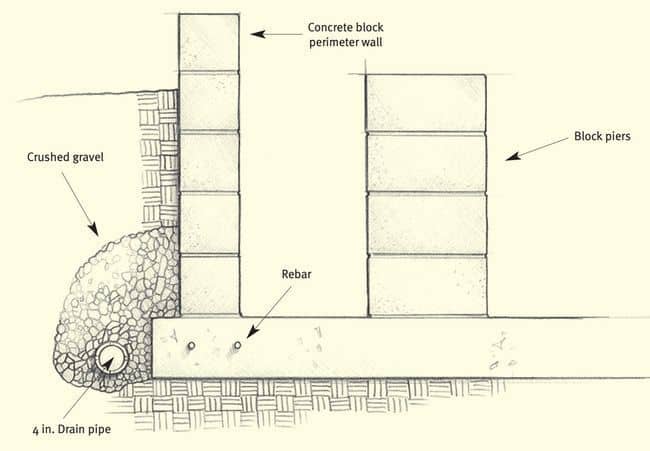

HUD’s Home Builders’ Guide to Manufactured Housing states that slope for manufactured homes should be at least 4-8%. If a slope is not possible there are other methods, such as a drain pipe system like the illustration below:

Conclusion for Manufactured Home Site-Prep and Installation

Manufactured home site-prep and land development is a complex, multi-faceted subject. That’s why an experienced installer is so important.

There are so many different things that can go wrong or create unsafe and unhealthy environments for a home and the families in them. You often hear about ‘toxic trailers’ but in many cases, water was pooling below the home and creating a perfect home for mold and mildew which was making the families living in the home very sick.

Unfortunately, a lot of manufactured home dealers don’t offer site analysis or help buyers enough to understand the importance of manufactured home site-prep and land development.

We’re not suggesting that you be a pest to your installer or general contractor but don’t be scared to ask questions and get involved. Knowledge is power!

We believe better buyer education about home installation and setup decisions, financing, and home maintenance would create happier homeowners and lower complaints in the manufactured housing industry.

Share your manufactured home site-prep and installation story…

Do you have a good or bad experience about your manufactured home site-prep or installation? We’d love to hear about it in the comments below. As always, thank you so much for reading Mobile Home Living!

Featured Image Source: Gleeson Mobile Home Service

Settling, cracked slab on two sides of the manufactured home may need grading and to move water away other than the already down spouts in place to keep the integrity of the underneath of the home good and remove sloping/pooling water during rainy season in Florida. Any suggestions?

Can anybody recommend a company that provides services in eastern Ohio?

Im am clueless but considering buying land and putting a mobile home on it. Need information to understand the cost and the process. I’m looking at S. Idaho or N. Arizona. I hope I can find some help here as I am just beginning the process and truly know only enough to be a danger to myself 🙂

I hope you get some resolutions to your issues. Make sure you do all your contact with the company in writing, keep accurate notes. You can find information about how to file a complaint if you don’t get your issues resolved here: https://mobilehomeliving.org/mobile-home-living-tennessee/

We used Monroe county Mobile home in Madisonville, TN, we have had nothing buy problems, it has been 3 months and we still don’t have proper drainage, no drains, still waiting on the front door to be fixed so it would lock. Monroe did not properly grade, nor did they grade enough so we have flood water running past our front door, pooling deep on the sides and running down our hill and exposing our septic tank.

Great article. Thank you

Thank you so much, Victor! Your comment means a lot to me!

I finally got the 1965 Airstream Safari I had been dreaming of and it’s about 80% restored so I think I’m ready for the Spartan now! Fingers crossed that one will fall in my lap someday. Thank you for your kind words! Happy Holidays!

Crystal, Thanks for your continued hard work to publish these articles. While I am currently a stick-built home owner, I continue to learn from your research and can often apply the principles to my home. I did own a double wide home several years ago. I wish I had your knowledge then. I dream of remodeling a vintage Spartan or 1960s mobile home some day. I’ll let you know if I ever accomplish that. Here’s to your continued success. Happy Holidays!