Proper manufactured home installation and setup is vital to your home’s health. Simply put, there is nothing more important than having your manufactured home installed and setup correctly and keeping it level.

Improper installation will result in serious damage. The stress on one small part of the structure impacts the entire home. The home will age quicker and the stress causes warping and bowing. After a short time has passed, the homeowners will begin experiencing issues such as leaks and it just goes downhill from there. Unfortunately, by the time the minor issues pop up major damage has been done to the home and it can be expensive to repair or correct the problem.

Education and inspection are the two best defenses against improper manufactured home installation and setup. If a homeowner understands the installation process and is able to ask the right questions they can ensure it is done correctly.

Manufacturer’s Home Manual

Regarding manufactured home installation and setup, the builder’s instruction manual shall trump all others.

Think of the national HUD standards as being the base regulations. Their standards are nationwide, but each state has its own (possibly) higher standards based on its average soil and climate environments. The manufacturer’s installation manual will meet all HUD standards, but it is usually much more detailed and will have higher regulations, so it should always be followed.

Click here see for our Directory of Mobile Home Manuals.

The manufacturer’s installation manual will provide details and specifications to meet HUD standards and is usually much more detailed, so it should always be followed.

HUD Regulation for Manufactured Home Installation and Setup

Before 2009, there were few regulations or codes set on a national level to mandate or control manufactured home installation and setup procedures. Several states provided their own guidelines, but minimal standards varied and little to no checkpoints were in place. Thankfully, that’s changing a bit.

Choosing the Right Installers

Home buyers are often put in an awkward situation when it comes to installing their homes.

Typically, a dealership will either have its own installation department or subcontractors or will recommend contractors. Since most home buyers aren’t going to know many installers, they will just use the one recommended to them.

Don’t feel like you have to use the installers or contractors that the dealership recommends. By law, they have to see the home through to the very end regardless of which company does it.

Take your time when choosing the installer for your new home. You just paid thousands of dollars for a home, so you need it installed properly to protect your investment.

Many states require all installers to be licensed and bonded. Google search the name of your state and the term ‘licensed manufactured home installer.’ The search results should include a link to your state’s HUD agency (or relevant office). Click here for a listing of Florida’s licensed installers.

You will need to check that the company you choose still has an active license (bonds and insurance are required -if they lapse, the license is no longer active).

Manufactured Home Installation and Setup Terminology

Learning the lingo and terminology used in the manufactured home installation and setup process is the first step in understanding the process and ensuring that you get your home properly set up.

A few common terms you should know (courtesy of the Florida Manufactured Home Setup Manual):

Dealer Installers are employees or subcontractors of the dealership where you buy the home. In the US, manufactured home builders cannot sell a home themselves, and there has to be a middleman or dealer (there are a lot of loopholes where builders really are the dealers but through a different company or entity but still owned by the same corporation).

A licensed Installer is an installer that is not a direct employee of a licensed dealer or builder. They must be licensed and bonded if state law requires it.

Stabilizing Devices are piers, footings, ties, anchoring equipment, anchoring assemblies, etc. that support and secure the manufactured home.

There are two main types of foundations, permanent and non-permanent.

Permanent Foundations

There are several types of foundations that a manufactured home can have. The permanency of the installation, chosen appearance, and the home’s location will determine which foundation is used.

If a homeowner owns the land and has no intention of moving the home again, a permanent foundation is usually the best. This kind of installation allows the homeowner the ability to retire the manufactured home’s title and get the property classified as real property.

The three main categories of permanent foundations are floating slab, roll-on, and pit-set. There’s also the basement and roll-on foundations.

Floating Slab Foundations

A floating slab foundation is a poured concrete pad with re-bar or J-bolts installed into the concrete so that the tie-downs can be attached to them instead of Helix Anchors.

The concrete floating slab foundation is usually only 6 inches thick, but due to the way the concrete is formed and shaped, the home can move along with the slab when the ground freezes, avoiding the possibility of cracking the foundation or damaging the home. There is a variable to the single floating slab foundation where two strips of concrete are used instead of one large slab.

Roll-on Foundation

Roll-on foundations are used when a homeowner wants the home to be even with the ground level. A deep foundation is dug out, and reinforced walls are poured so that the home looks as if it is sitting directly on the ground.

Pit-set Foundation

A pit-set foundation is similar to a floating slab, except the slab is poured one or two feet below ground level, and walls are poured around the perimeter of the foundation to be even or slightly higher than the ground level. This creates a completely enclosed foundation.

Basement Foundation

Basement foundations are self-explanatory. A full or half basement is built under the home. This single wide is installed over a basement foundation. You can read more about that home here and here.

Non-Permanent Foundations: Pads and Footings

For non-permanent foundations, there are two main choices, pads and footings.

A surface set pad foundation uses cinder blocks on level ground.

A pier footing foundation system consists of several re-bar reinforced concrete columns that are poured to set directly under each pier or block set of the home. These columns may or may not meet the frost-line depth for that location.

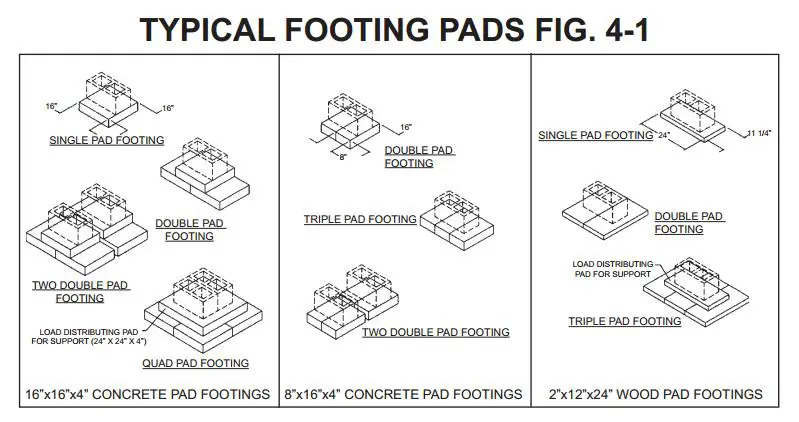

The size of the foundation is determined by the soil bearing capacity and the size of the pad. Each state will have a minimum foundation pad size and will state what material the pad can be constructed with. For instance, Florida’s smallest pad size is 16”x16” and can be made of concrete or plastic; wood is unacceptable.

The size of the foundation determines the pier spacing and the amount of weight that each pad can carry. The manufacturer’s installation manual will provide additional information on proper pad sizes. Below is a footing pad diagram from a Skyline Homes manual:

Support Piers

Site-built homes have stem walls on the outside, directly under the exterior walls. Manufactured homes have piers positioned under the chassis.

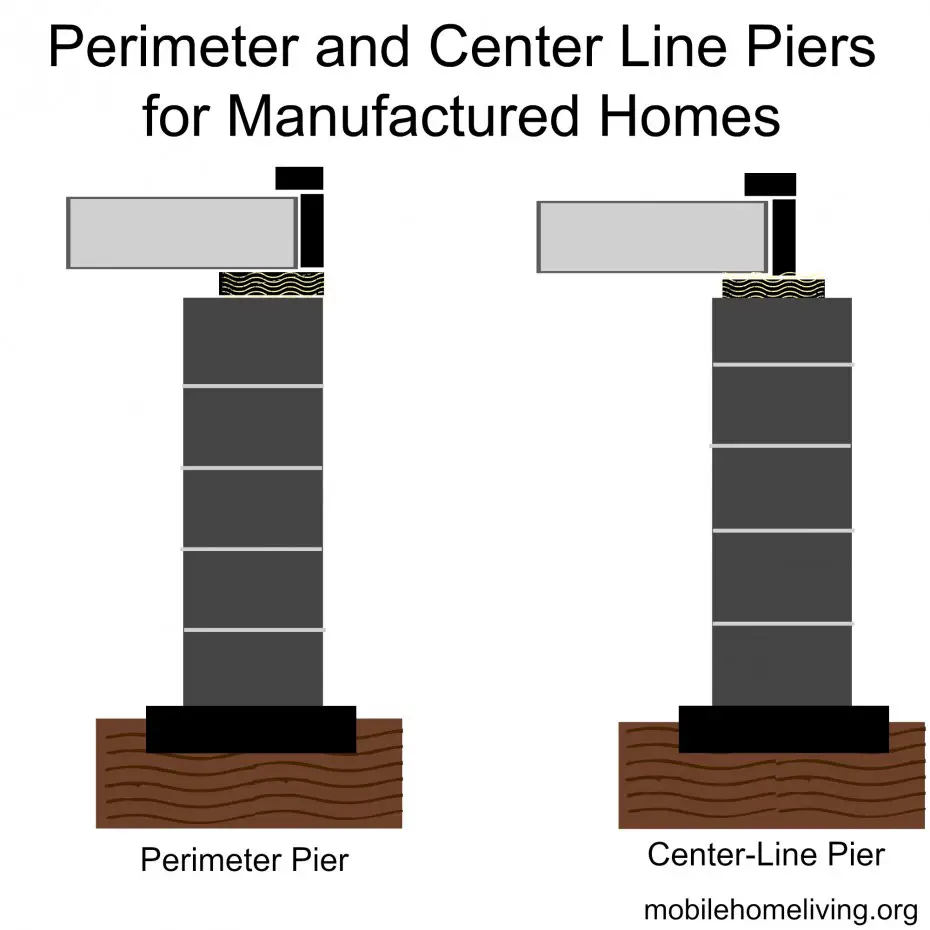

Piers are made of steel or concrete. There are three main support areas on a manufactured home: the frame or I-beam, the center line, and the outside perimeter.

Perimeter piers must be centered under the I-beam and at the marriage line if the home is multi-section. The spacing of the piers must be carefully calculated by the installer. The block plan discussed earlier is used to determine this spacing.

There are various rules regarding the different piers. Clearance, pier height, single vs double stacked blocks, shims, and many more guidelines must be followed. The homeowner should research to know the specific rules for the home type and the location.

Blocking Plan

A blocking plan will be included with each home installation manual. It will be similar to the one below:

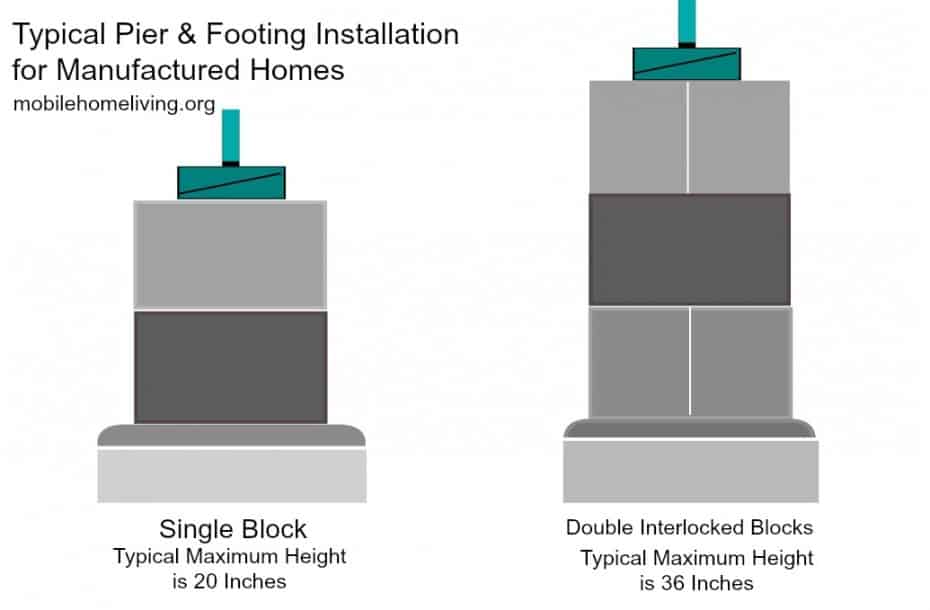

The illustrations below portray the various types of piers and footings that a manufactured home can have.

Note: If a double interlocked pier is filled with concrete, it can usually be used up to 80 inches in height.

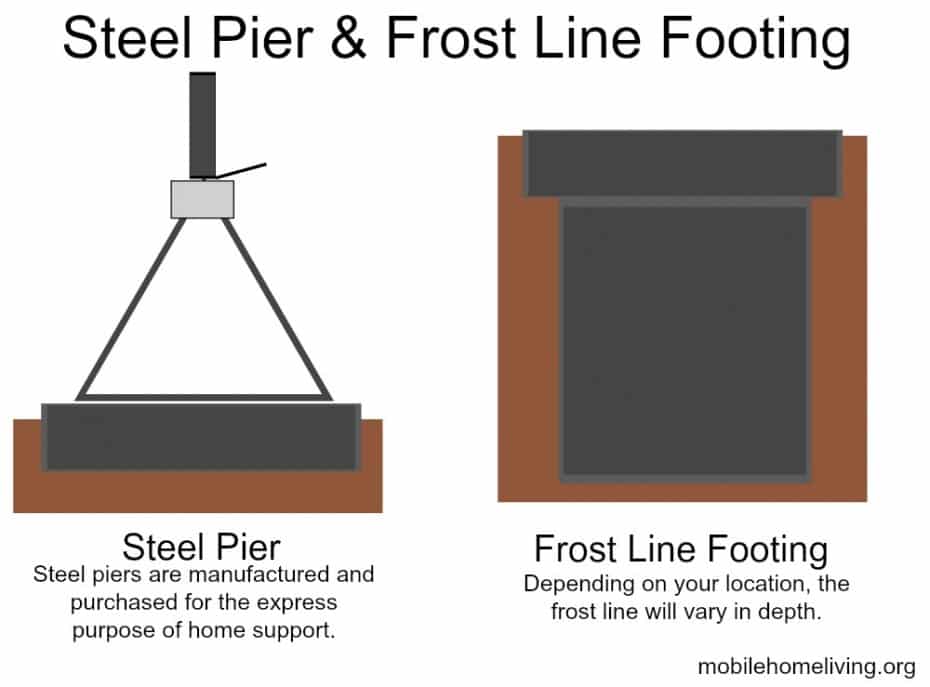

Steel pier and frost line footer:

An illustration showing the difference between perimeter piers and center-line piers:

Anchors and Tie-Downs

Anchors, or tie-downs, are used to anchor the home’s frame to the earth or the foundation.

Improper anchoring or tying down homes is the main reason we see so many homes on their sides on the weather channel. It is not the home itself but the lack of tie-downs or anchoring systems used on the home.

If a new manufactured home is correctly tied down, it can withstand over 110 mph winds.

Types of Anchors and Tie-Downs

Ground Anchor – any device approved by the DMV that is used to secure a manufactured home to the ground to resist wind forces. Ground anchors are rated by working load, which is the maximum load for design purposes. The ultimate load is the working or design load multiplied by the safety factor of 1.5.

Frame Tie or Tie Down – any device or method approved by the department and used to secure the mobile/manufactured home or park trailer to ground anchors to resist lateral wind forces.

Vertical Tie – any device or method approved by the department and used to secure the mobile/manufactured home or park trailer to ground anchors to resist vertical or uplift forces caused by the wind.

Over-Roof Tie – any device approved by the mobile/manufactured home manufacturer or listed by the DMV to be used to secure the manufactured home to ground anchors to resist wind forces. Ties may be installed over metal roofs.

Hire a 3rd Party Inspector

The most important advice I can give you is never to sign anything until the home has been completely installed and inspected by a 3rd party that is not affiliated with the dealer or the installer.

Hiring an independent inspector will cost you a few hundred dollars, but it is money well spent. Only after they have inspected everything should you sign anything.

Learn how to paint metal siding on a mobile home here.

Annual Checks Using a Water Level

A manufactured home should be re-leveled at regular intervals. Homes with complicated foundations or that are high off the ground should be checked annually for the first few years to ensure that settling or shifting hasn’t occurred.

Less complicated installations can probably go 18-24 months between checks. A water-level costs around $50 on Amazon, but you can make your own. Here’s an entire article about leveling a mobile home (and making a water level).

Conclusion

In conclusion, manufactured home installation and setup is one of the most important issues you face as an owner.

Most issues that occur to manufactured homes can usually be traced to a home that’s unlevel or was not properly installed.

As always, thank you so much for reading Mobile Home Living!

I’m trying to find someone who can set up my double wide mobile home.

Hello,

We live in AZ and are considering the purchase of a triple-wide manufactured home with an “Engineered Block Stem Wall” foundation. The home was built by Palm Harbor, which I understand is a reputable builder of homes and RV’s. The house is from 2007. We know nothing about manufactured homes.

I just wanted to ask if you consider an engineered block stem wall construction to be quality– From my readings it appears to be the foundation of choice for site-built homes as well, so my thinking is that this is a good choice for manufactured homes, in terms of permanence, stability and safety. I can’t seem to find specific articles on the use of block stem walls for manufactured homes. Also, based on online articles, I can’t determine if this is considered a “permanent” vs. “non-permanent” foundation type?

Also, I know it is difficult or impossible in some cases to get financing to buy a manuf. home, which can be due to the foundation type. Does stem wall construction, because it is also used for site-built homes, imply good financing options? This would be a consideration as we would eventually need to consider the resale value of the property.

I assume any issues will come up during inspection, but are there any questions you recommend that we should ask the seller regarding the foundation?

Thanks for any insight you may have!

Erroll

Sedona, AZ

Hi Cathi,

You may just need a pro to come in and reattach or tighten your marriage line. It’s an issue that a lot of manufactured home owners have but thankfully it can be fixed in a day. best of luck!

Patricia – what happened to your home? My roof landed in my front yard due to a straight line wind ( I am in Oklahoma) my marriage seam is having the same issues. It is like my house is coming apart into two pieces. What did you do to repair or fix your home?

Oh Patricia,

You need to have that home inspected for damage and either reinstalled properly or replaced. For one, the installer should have been using safety ricks under the home while it was being installed. A manufactured home will never be perfectly level but it shouldn’t have that much of a separation. If you haven’t signed anything yet please don’t until the home issue is fixed. Best of luck!

I had a new 32 by 80 installed on my property. During setup jacking the front half to the back something happened and there was a Big Bang and I saw that half roll like on a wave. When they finished putting it together there is a gap between the marriage wall from 1 1/2 inch at one end to 2 1/2 inches at the other end. The roof on one end is 3 to 4 inches longer on the front half than the back.

Hi. I am buying a 1980 Windsor 14×70, 2BR, 2BA Mobile Home and am having trouble finding details I need to provide to the State so it can be moved as well as titled. I have looked online but have found very little info on Windsor Mobile Homes, Inc. from Bristol, IN even though seem to have been in business for atleast 30 years, since the 1950s.

I am looking for floor plan info, VIN, Model #, etc. It needs renovation at minimum but it would increase value if I could find more details.

Hi Keith,

Sounds like you’re dealing with a standard re-leveling issue. Manufactured homes need to be re-leveled regularly (in some cases every other year when the ground is soft). This is considered a standard maintenance issue and since you’ve already bought the home and didn’t know to look for it during the buying process I doubt there would be anyone responsible but you (there are little to no installation laws for manufactured homes). Parks would not be liable for the issue as it’s def a home issue. Not every home is put on pads though that is an ideal situation. Here’s an article on re-leveling. Since you know the ground is soft it is a good idea to go ahead and buy a water level and check the home every summer.

Best of luck!

Hi Rhonda,

That was a lot to read and I’m terribly sorry the kids are dealing with this. I’m just going to answer as my brain thinks so bear with me.

I dislike parks for these kinds of reasons. Tenants have little to no recourse and with a land/home package, it’s double the nightmare. I’m so glad they have you on their side. You are doing everything you are supposed to be doing – mostly writing letters and keeping extensive records of everything.

I think 32 states have their own HUD state agency that you can contact directly for complaints and issues when it comes to manufactured homes (builders and dealers). The other state requires you deal with the HUD office in DC. You will also want to contact your state’s manufactured homeowner’s association.

Unfortunately, parks are not regulated nationally at all and most states give parks absolute power to do anything they want. For instance, in Louisiana, a park only has to give a tenant 10 days to move their home if they decide to close or sell and I believe even evict a tenant. No one can find a place to put a manufactured home or come up with the thousands needed to have the home transported.

Every new manufactured home has a 1-year warranty but that only covers the building of the home. There are no national regulations or laws mandating the installation of the home even though that’s where the majority of issues stem from. Keep writing the dealer and the installers. Stay on them and create a paper trail so that there is clear proof of your complaints. However, with installers, there really is no recourse other than small claims court and BBB (which is pretty much useless and a scam in itself).

As far as the grade of the site, that’s really a fairly simple fix. HUD recommends that there be a 6″ slope for the first 10′ around the home. A little dozer work and a french drain or two can remedy just about any kind of water or moisture issues on a site. I’ve seen manufactured homes installed in near swamps in SC but with the right grading and preparation, it was turned into a fine lot. You can read more about manufactured home site prep here.

You are correct, homeowners are responsible for the re-leveling of their homes and it’s recommended to do it 2 years after install and then 3-5 years thereafter. It’s important that the home be installed correctly from the get-go.

How did they do the footers? Were the poured below frost line? If all that was done I don’t see how they didn’t grade it as well. There are several installation ‘systems’ – many states allow them. It’s special piers and pads that the home sits upon. If they used those and didn’t pour footers of any kind then there was likely no site-prep done at all and that’s the issue. The tie-downs are very important to make sure that they are installed at every place the manual states. Get the manual for the home, it will tell you exactly what type of pier configuration is required for the home (every home is different based on layout and weight).

Hope I helped. I tried to cover everything you mentioned! Best of luck!

Hello,

I am having a difficult time with the park who sold my daughter and her fiance a brand new home, the seller placed this home in its current location and the homeowners had no say where it was placed.

First, we found out this week the is missing the 4 anchors required for installation, the installer admitted this and yes I have it on video although they were unaware of my doing so. There is absolutely no doubt that the installation as well as the site prep, was improperly done per not only Texas Code but Fleetwood Homes guidelines and since this is a HUD home there may be more rules broken.

Next, the seller placed the home on a lot that is non-conducive for a manufactured home due to the natural drainage that occurs on the lot itself. Since the new homeowners are responsible for any future releveling after their first as well as having to “build up” this lot to attempt to keep water from entering underneath their new home this will occur at a rate of four times more often than a homeowner who owns a home that was properly installed, the site preparation done correctly, and on a site that does not allow for water running underneath it. This will be necessary yearly without a doubt and you cannot permanently keep the water from entering under the home.

Currently, I am preparing a letter detailing these facts proposing that seller either move their home to another lot of the homeowners choosing or alternatively that the seller be responsible for any out of pocket expenses for any releveling over and above that of a home that is properly installed and without issues that this lot present. I will contact the agency in Texas if they choose to do neither and possibly retain legal representation for my daughter if necessary.

This has been a nightmare of major proportions for these young kids and I am wondering if you may have any other laws that you are aware of that I might be able to get the seller to do the right thing here. What should have been a great experience has turned out to be the bain of all of our existence. But, knowing the law, it never hurts to seek more information.

Also, when the installer came out and reviewed the new home’s installation, he mentioned that the home has a “system” it looks to be a V looks like led pipes in a triangle, he told me that it is approved in these installations I cannot find that. I do know that all the other homes out there that have been recently installed DO NOT have this contraption underneath them! I am concerned, should I be?

Sorry to hit you with so much, but this is important and I do not wish to see these young kids be taken advantage of.

Thanks in advance for any information you may be able to pass this way!

R

Where I live, no seller will let you have the home without getting paid first. It sucks, but it is the way they are.

Hi Sara,

You won’t be able to pour your pad because of the temperature (which is why buying a home in the winter is a pain). However, you didn’t mention that, you mentioned standing water which is not good. All home installs require proper grading so that your lot cannot hold water – in fact, the gov. require a 5″ grade for the immediate 10′ around the home. Has your installer done this?

If your lot is too wet to start because it is holding water or moisture it needs to be graded better so that the water runs away from the home’s footprint. If it’s graded properly it wouldn’t have a chance to sit there and create such an installation issue. This post explains a little more.

Best of luck!

Hi Sue,

It is so difficult to find help that is willing to work on mobile homes. I don’t understand why – the homes are easy to repair (or maybe I just think that because I was born and raised in them). I would try Craigslist and/or Facebook Marketplace. I would also call up your local manufactured home dealership and your local mobile home supply stores and ask if they have any recommendations. Please call references and check backgrounds on anyone you find online. (Oh, if you have a local trade school or vocational school in your area that has a construction department you may be able to get the students to come out and help you).

Best of luck!

We are currently waiting on our home to be delivered and set up. It has to meet FHA guidelines so their will be a pad built along with concrete footers. We were told it’s too wet to start. Our lot holds water after rain. Question is the yard seems to stay moist. How long do u think we will be waiting for a home?

Crystal, I have bought a single wide mobile with attached 1/2 basement on 3/4 acre . I need someone to help with some work,,, ( going under and checking the ducts/ piers/ waterlines/ ect,,,,My problem is I dont know where to look for a HANDYMAN,,, with the knowledge of mobile homes……I live in North Judson Indiana.

Hi Ashley,

You will need to have your home installed professionally. There is a ton of work involved and in most states, all mobile home setups and installs must be done by licensed and bonded professionals or you can’t even have utilities installed.

Your land will need to be analyzed for grade (and moisture channeling) and your soil will need to be tested so they can determine the proper foundation to keep your home safe and healthy.

I’m putting an article together right now about site prep (your question inspired me!) I’ll have it up ASAP. Best of luck!

Hi we bought a 34×76 mobile home. We are getting our pad ready for installation but i am wondering if we have the full concrete slab poured for it does it have to be done a certain way or how should it be done

Hi Dustin,

If you own your home and just rent the lot then you are likely responsible for the piers and tie downs as well as the plumbing to the mainline connection. Parks are typically not responsible for much of anything having to do with the home itself (only roads, trash, etc for the park itself) unless your contract states differently. Anything to do with leveling (stacks, piers, tie downs, etc) are homeowner issues regardless of location. The park may have helped you install your home and plumbing as a courtesy at move in but that would be as far as it goes.

You’ll def want to get those piers fixed as soon as possible. The strain can cause structural damage to the home that can result in leaks and quick degradation.

Best of luck!

Own single wide on rented lot in a older park in Central NY. Owner of park replaced one trailer and was forced to do pad, provide blocks, and tie downs. My lot is in very poor condition, dirt, with some definite hydraulic water pressure issues possibly from septic lines running along trailer less than a foot away and possibly under lot. The old stacks of bricks used to support trailer are deteriorating rapidly and trailer is shifting. Who is responsible for replacement of brick and lot improvements to stop future damages to my single wide?

Hello!

There is a better way to place homes and if done right it can save you a lot of money on heating and cooling. I’m not an expert though so here are some articles that will help you understand it better:

Mike Holmes: Use orientation of home to directly benefit your wallet and your wellbeing

How to Position a House on a Lot for Maximum Energy Conservation

Best of luck!

we are planning to place a mobile home but not sure how to place it thinking about the winds/storms we have in Oklahoma, Is running it east- west better over north- south, or is there a better direction to set it?

Hi Leonard,

They can use jacks to raise the home onto the foundation. you’ll want a trustworthy and experienced installer so make sure you do research on those available in your area. I’m not affiliated with any companies, dealers, or installers so I can’t recommend anyone. The dealer you purchase the home from will be able to guide you through the whole process though. Best of luck!

I would like to buy a double wide home 24′ X 52′ and place it on a 10′ high block foundation, 2 to 4 garage doors, is it possible and how do they raise it up to put it on the foundation. In southern NJ.

Hi Scott,

I don’t think it could be done simply because in Ohio your frost line is 32″ and there would be no way to dig under the home unless you did it by hand. Is your home sinking? Is there a particular reason you want to change your foundation? Are your straps properly placed? I’d put more energy into strapping the home than the pads if the home isn’t sinking anywhere.

Best of luck!

Hello. I have two mobile homes joined side by side- not a married double-wide. They are NOT sitting on concrete pads and I regret not having that done but it is what it is. What I do have are 24×24 black ABS plastic pads followed by two treated 2x10x20 placed side by side on those pads and the 16×16 square block piers on them. So I have a 24×24, a 20×20, then a 16×16 inch pad/pier footing system under the home. They are located incrementally. What I am wondering is if are there any known way of installing concrete pads ‘after the fact’?

Post and beam support ten feet of the ground is just asking for trouble. Unless you live in a flood zone, it would have been much better to build basement walls and maybe incorporate a basement or an 1/2 basement into the build. Basement walls, done correctly won’t shift or sag like piers and posts. If you must use piers and posts, the taller posts should be much deeper in the ground and should have some type of cross bracing to keep them square. The problem here is that they can and do shift, if not poured into a single foundation footer. The height also will be a problem if there are horizontal stresses. I have seen and know of single wide mobile homes, built in the 50s, still serving the same family, because they used a foundation like a stick built raised foundation of that era. They have never had door, window or floor problems. This is a retreat at a lake, when it gets used, there might be 15 people there for the whole summer.

Hi Tom,

Ground prep is very important for manufactured home installations. You likely need dirt to create a slight bank so that water from the home will wash away from the home. It’s a mound that you put the home on but it has to be level and the soil/ground has to be tested to make sure it won’t sink too much.

I’m about to put in a new double wide home in a park. The installer says it need s to have some dirt spread if I want to have a pad under the home. Do you know what the purpose of a pad is, and are they necessary?

We had our double wide moved two years ago. We are now having our roof redone. The roofer noticed that the gap in the marriage line is over 3 inches on one end and and he stated there is only one bolt along the marriage line. I called the company we had to move it and he said we had a 90 day warranty ——sorry. what can i do….?

Hi Jeff,

You can. While you are under the home you’ll want to find what is causing the sag. Settling is the most common reason and that will just require additional support. This PDF should help you: HUD Guide to Foundation and Support Systems for Manufactured Homes.

Best of luck!

Hi Bob,

I’m not personally familiar with IL code but I was able to find the state’s manufactured home installation guide and code book. Here’s the link: http://www.idph.state.il.us/envhealth/pdf/guideinstallhomes.pdf

Here’s another code book for IL: http://www.dph.illinois.gov/sites/default/files/publications/manufacture-home-installation-code-870-042716.pdf

Best of luck!

Our mobile home built in 1978 was destroyed by fire. I would like to replace it on the existing slab, but I am told the the new regulations in IL will not allow it. Anybody know about these new regulations?

Hi Joe,

Every state/county/town has different rules. Contact your county building inspector. They will be able to tell you faster than any Google search. If your county doesn’t have an informative website you likely won’t find the most updated information.

Best of luck!

Hi Eric,

There are a lot of factors involved and it’s all over my head. Sorry!

I need an answer. I live in Phoenix, az. I’m told stem walls is required to get permit.

Hi Susan,

It sounds like you have a ducting issue. 80 foot long homes are awesome but they have a couple of disadvantages such as heating/cooling. Ducting is pretty straightforward on manufactured homes but you could have a rip or hole. You may want to have the ducts under your home re-wrapped and insulated. I’m not real knowledgeable about HVAC but my first thoughts are the ducts or you simply need a larger unit (or maybe just a blower?).

There are some ventless wall-mounted cooling devices that you could add to your rooms, too.

Best of luck!

I have a 2000 model Spirit Home, double wide 32×80. Has perimeter air in thru most of the house. Most of them do not blow good enough air that you feel comfortable in the rooms. I have 3 bedrooms that is to hot in the summer to sleep in them without a fan blowing on u. The rooms are not braced for ceiling fans, so have to use a floor fan. What can I do?

They have never blown real good, but seems like over the years it has gotten worse. U can barley feel air blowing out the vents. The air is cold, but just does not come out the vents hard enough. Help!!!

Hi Jessica,

I’m so sorry you are going through this. It’s maddening and disheartening. You are experiencing one of the most common issues in the manufactured housing world – issues due to improper installation and a lack of tie-downs.

The home SHOULD have been properly installed to the manufacturer’s specifications. The dealer SHOULD have educated you about the different installation ‘packages’ and then ensured that the home was in fact installed to the manufacturer’s standards but none of that happened. Unfortunately, installers have several ‘outs’ when it comes to this kind of thing. If you only paid for the standard installation service (without understanding there were any other options) and if you signed the final paperwork stating you had inspected the home and were satisfied with it, you will have a fight on your hands. This isn’t fair and it is a serious issue that needs to be corrected. Unfortunately, we little people have no power so the regulations we need to protect homeowners will likely never be implemented.

In a perfect world, I would tell you to fight till you couldn’t fight anymore but this isn’t a perfect world. Sometimes it’s quicker and easier to take what you can get and be done with it because fighting these types of battles is long and frustrating and that’s done purposely – the longer they make you wait the more likely you will be to drop the claim.

Since the home has suffered a shock, it may be more susceptible issues so be very diligent and inspect every inch every month or two and watch for leaks.

I wish you the best and I hope you can get the result you want. Please let me know how it goes.

My single wide mobile home was knocked off of its foundation due to semi-strong winds on April 3, 2017; causing damage to my home. I have had two licensed contractors to come out and assess the home in which they have both informed me that the unit was not tied down properly. I purchased the home in November of 2014 so it has only been 2 1/2 years. I am dealing with my insurance company who has claimed that the damage to my home is only minor and have agreed to only provide me with 1/4 of what it will take to repair. So far I’ve collected a few written quotes to prove that the home was not tied-down properly (per the manufacturers own installation set up guide). Any suggestions on what I should do? I am beginning to become a bit discouraged. I have looked for an attorney and its hard to find someone to take this case.

My name isMartele Spataro and I’m a Dealer. I have a house coming in NEXT Friday the 21st, and greatly need an install contractor for a home being delivered to Napa. Please call me at1 (707) 291-1891 or email: [email protected]. Thank you

Hi Edith,

Under no circumstances should you release funds until the home is absolutely to your liking and passes inspection. Withholding funds is one of the only powers you have to ensure the work is done properly.

Hello!

I love your site: mobile home living , I started searching google and I found you , since then got hook! Lots of good info , thank you soo much .

We are buying a brand new doble-wide manufacture home in north Ca.

It is normal procedure for a manifacture to ask to be paid in full even before they start with the foundation where the house is going to be placed?

We got a letter from the escrow company saying the dealer requested the all founds to be release at once , since then dealer and we agreed on 4 steps on how the funds are going to be release. But again we got release forms from escrow saying other than what dealer and we agreed on, when the escrow agent was also notified of the new terms .

Now , we don’t know what to think , seems like they are trying to get paid the full amount even before the whole project is finish .

What do you recommend ?

The dealer only gave us 2 reference wich I contact only one and he spoke only beauty about them .

Thank you again!

Hi Mary,

There are only a couple of websites that collect reviews on manufactured home dealers and builders. I wish there was more though. Google ‘Manufactured home complaints’ and you’ll see the sites (I can’t for the life of me recall their names and I’m not able to search Google easily right now).

Ask around the parks, and check your state’s BBB. You are definitely doing the right thing by researching and buyers that research well are usually the most satisfied. Best of luck!

Hi Kate,

I’m afraid your question is out of my league. I’m not very knowledgeable about carpeting and the effects of freezing weather on a home. I would guess that as long as you have no other signs of stress on the home (doors and windows not shutting easily), then it is just the cheaper carpet material interacting with the expansion and contraction of the home (which is natural to a degree).

Sorry, I can’t be more helpful, but I’m very interested to see what you find out. Could you keep me informed once you get it figured out? I’d love to see the new carpet once installed, too! Thanks!

I love our 2011 mfged home. Hubby and I are seniors so we live alone and opted for many upgrades but the one upgrade not offered was for better quality carpeting. I knew from day one it wouldn’t hold up well, and it hasn’t. The guy who came to finish laying carpet in the hall after the home was installed/set up said the vinyl flooring (laundry room, bathrooms & foyer) should last 20 yrs but the carpet and under padding is crap. My question is this: Our home is on a pier foundation, and the crappy carpet it buckling in EVERY room. Is that just because it’s cheap, crappy carpet, perhaps in combination with poor installation, or does it have anything to do with the fact that there are big temperature fluctuations in the floors with the pier foundation & crawl space. (We’re in MN….think -20 [sometimes worse] in winter, 90+ in summer.) We want to replace the carpet this summer, and because the floors are cold in the winter, we want to get carpet again (better quality!) but want to make sure that the buckling is due to the poor quality of the existing carpet and not the temperature fluctuations below the floors, and, therefore, will keep happening again and again no matter how much we spend on carpet and installation. Any insight or advice will be very much appreciated.

Thank you for all the information on your site. We are looking to buy a home this summer and measuring the pros/cons of manufactured homes. Frankly, it seems overwhelming. I can’t seem to find a lot of positive reviews on homes and dealerships available in my area. (Arkansas)

We have a 2600 sf manufactured home (2005) and are just in the process of having a stem wall installed as the original installation was just rebar and plywood – then backfilled and a skirting put around the part that was still above ground. Everything has been dug out, the footer has been laid and the block steam wall is complete. We live in Arizona and there seems to be some disagreement between us and our contractor on whether the block wall needs to be sealed from the outside before we start the process of re-landscaping. While it is dry most of the time, during monsoon we get extremely heavy rains and I am not sure we want all that water seeping under the house. It is on piers and pads. What would you recommend?

I’m sorry. One more question…

The double wide we just bought (which is 20 years old) has a problem with the heating system.

It has forced hot air heat provided by a natural gas furnace. The problem is that heat only comes out of the registers on one side of the home. Nothing comes through the registers on the opposite side. We’re hoping this will be a simple fix but are concerned. The duct that connects the two sides of the home appears to be connected. We really don’t know if this has always been a problem from the beginning or not. Not likely, I would think, because the home was originally set up as a park model. At some point this home had sat vacant for a number of years and was sold at auction due to property taxes not being paid. Is it possible an animal built a nest in the ductwork? Or what else could cause this? There was also a freeze-up during that time and all the water supply lines were replaced.

Can anyone familiar with plumbing and heating resolve this problem or should we try to find someone who specializes in mobilehome setup and repairs?

We just bought a 1996 double wide manufactures home (mobilehome).

It is on piers. A few questions:

1. What is involved in removing the wheels and axles. Does the home have to be raised up to get them off?

2. We have cathedral ceilings but one spot in the living room is damaged. Is it simple to remove & replace just the damaged area and still have everything blend in with the rest of the ceiling when done?

3. We are also interested in having the home checked as a maintenance procedure to make sure it hasn’t settledone over the years. The closest door in the M Bedroom will not close. It appears to be out of square, which I take as a sign of settling.

Local banks will not mortgage a mobilehome with wheels and axles still attached. We don’t need a mortgage but when it comes time to sell it, a sale will be easier if the home qualifies for a mortgage.

Thanks for your input Ted. Sounds like you def know your stuff!

There is not enough information to assume the setup was faulty based on the info provided.

On a set like was described, post and beam set 10 feet off the ground, my first thought is how often was it releveled?

Home owner maintenance is a very critical in any home and more so in a manufactured home.

Some manufacturers will say at least every other year and a possibly every year on a standard set. With a set like the one described, I would say every year.

Also, cracks are very common in manufactured home with tape and texture walls. Typically exterior walls to interior wall corners, wall to ceiling and marriage line are very common.

I would be interested as to what constitutes a ” poor installation”.

All manufactured homes installed in the U.S. other than a Reservation are inspected by a person with credentials to represent HUD whether directly through a state agency or by Agreement.

Dirt can and will settle even after being ” compacted” Which is a large portion of what would be described as settling. The relevel will allow for that assuming typical circumstances and no frost heaves, expansive soil or other ground issues.

Drainage can play a large part in the amount of settling that can occur and something that should be addressed as part of the install and maintance. Sprinkler systems and landscape can play a large roll in settling and drainage issues, just to name a few of the things that get done after the install that can adversely affect the integrity of the home.

FYI, I have been in the manufactured home business for going on 32 years, I spent 8 years in the factory building them, park models, manufactured homes, modular homes and factory built buildings.

The next 10 years doing factory warranty service for most every manufacture in the south west.

The last 13 or 14 years doing insurance claims on manufactured homes.

While I don’t proclaim to know it all, I have seen quite a bit of settling and set up issues over the years, I just wouldn’t say the described situation is a poor setup with out a significant amount more information.

Tim

Hi Steve,

There is a big difference in modular and manufactured. Modular homes have to meet your local building codes and are not built on a chassis (just sections). A manufactured home is built on a chassis and complete directly from the factory. Manufactured homes only have to meet national HUD building regulations. The price difference is quite a bit, as is the insurance, taxes, and appraisal methods.

I am not experienced in any form of modular/manufactured home living, but I am considering the possibility. If I were to purchase a modular/manufactured home on some land and it does not have a stem wall, is it possible to have one installed after the fact? If so, would it be expensive?

Hi Cheryl,

Sorry you’ve dealt with shady companies. There are some good ones out there! Please have your home leveled as soon as possible. It doesn’t cost as much as you think and it can be done in a day. This will keep the home from aging and deteriorating quickly. If it goes too long the doors and windows won’t open, and the stress on the joints of the home can create havoc.

Best of luck!

Thanks for the advice. We have been in our double wide 10 years and everyday we see that our two halves don’t match. Not even the paint on the ceiling, and the floor doesn’t match. The patio door leaks and has since it was brand new. The cabinet doors and drawer fronts look like greese was poured down them. The newewt trick is to make you attach your land to the home

so that if you default on it they take your land too.

By the way we found a note saying Bubba tiled our floors over screws nails and everything.

Beware they are still crooks.

Hi Chris,

I saw a water hose gutter cleaning extension that may help. It had a long handle with a bend on the end and different sprays – might help get the small stuff down to an area that you can reach easier. There are also kits you can buy that click into the tops of gutters that keep debris out.

Best of luck to you!

Hi I am very upset I live in a moble home park and do a lot of repairs the biggest problem and i just cant be leave these set up crews would do this is the gutters around the carport patio theres no way to clean them without taking every thing apart some you can get your finger down inside but most you cant get even a knife blade this has damaged alot of porch decks ect because the water gets backed up from the mud witch you cant get out

Hi Alma!

Installation details will completely depend on your location. Your dealer will need to furnish you with the manufacturer’s guidelines and they should be able to tell you exactly what your local regulations are as well.

Congratulations!

Hi! Thank you for this information. I’ve been approved for a double wide mobile home mortgage. I was told I need to get the land ready by getting a basepad on the land to set the mobile home on. What are the different options for base pads? What is the best to use?

That sounds like the silliest excuse for poor installation I have ever heard. They are so good at making up excuses!

Here’s where it gets tricky though – after they install a home they will have the owner ‘inspect’ the home and sign off on it – by doing so you release the company(s) from all liability of an improper installation. Who would, in their right mind, have someone with absolutely no knowledge of a subject sign a legal contract stating that simply based on looks alone and whatever paperwork that’s been provided the home has been setup correctly? The manufactured housing industry would!

The cards are stacked against manufactured homeowners from the get-go – the industry is as sleazy and dirty as it gets and though it has gotten better since the 1990’s it hasn’t gotten that much better.

There’s only 3 real ways to get some kind of help and none are very good. The first is to pay for it yourself. You do need to get better support under there and the home re-leveled to stop the damage from getting any worse. It will cost but it won’t cost as much now as it will in 5 more years.

The second is the state agency funds. Each state has a fund setup for manufactured homeowners to get the repairs needed due to faulty manufacturing or installation but it takes years of frustration and paperwork to get anywhere. Here’s a list for each state, contact them and start the process to file the claim. If possible, get an attorney.

HUD State Agency Departments: http://portal.hud.gov/hudportal/HUD?src=/states

Every home that is sold has a percentage of the price go to this fund but there is rampant fraud and misuse going on with these funds in a lot of states (WV being one of the worse) so the chances of actually getting any help from these funds are slim to none.

The third remedy would be taking it to court. The paperwork is probably against you if you signed it but you may have a leg to stand on if you are willing to pay an attorney up front.

The companies will also tell you that your insurance will help you repair this but if you turn this kind of thing into your insurance the chances of staying insured is slim – you will be cut and you will have a hard time finding another insurer that you can afford.

I should add that in some instances a home must be re-leveled at regular intervals. Homes with complicated foundations (like yours, where the home is high off the ground) should be checked annually for the first few years to ensure that settling or shifting hasn’t occurred. They probably failed to tell you that though.

I’m terribly sorry you are experiencing this. I can only imagine the anger and disappointment you feel. I wish you the best. If there is anything I can do please let me know.

So what do you do when you have a manufactured home that was installed incorrectly? Our was installed in 2005 by the local dealer’s contractor. Ours is on a post & beam raised foundation. It looks like it sits at ground level in the front but it’s about 10 feet or so off the ground in the back. We’ve lived in this home since September 2007. It is developing stress fractures along the middle where the 2 halves come together and along the seams of the drywall in the ceiling. We also have a large stress fracture in the drywall in one of the corners (that was patched over by previous owner). There are also several spots on the back half (the raised half) that have squeaks in the sub-floor due to loosening of the plywood and the kitchen floor is not level. We were told by the local dealer that this damage was caused as a result of the unit having a front loader washer which is not recommended for our type of foundation.