Mobile homes become unlevel for many reasons. They can settle into the ground due to excessive moisture, experience ground heave, or can have damaged shims, or wedges. Loose and broken wedges are common, especially if non-treated or softwood was used. Re-leveling a mobile home does exactly what it says, it re-levels the mobile home so the weight is distributed evenly and properly. A level home is a healthy home.

Unfortunately, many mobile and manufactured homeowners don’t know that they need to check their mobile home leveling on a regular basis.

Can Average Homeowners Re-level a Mobile Home?

If the mobile home has a few loose or missing wedges or other minor adjustments a homeowner with moderate construction experience should be able to re-leveling a mobile home. Of course, the right tools would be needed.

If the piers are leaning or the home is extremely unlevel a professional must be called.

When Should I Check to See if My Mobile Home is Level?

Most installers recommend that mobile and manufactured homeowners check their home to ensure it is still level 90 days after installation and then every year after, preferably at the beginning of summer.

Signs a Mobile Home may Need Re-Leveled

There are a ton of things that can throw a mobile home out of level. One of the most common reasons is the wood used on the pier stacks can shrink and expand. If the wedges were installed across the grain they can get crushed.

- Buckled siding or roofing

- Doors and windows that are difficult to open and close

- Cabinet doors that won’t close

- Loose tie-downs

- After extreme storms (hurricanes, windstorms, earthquake)

- After building a porch or addition onto the home

- Erosion under the home

- Loose wedges

Tools and Materials Needed for Mobile Home Leveling

The most important tools a mobile homeowner needs to check level is a water level and hydraulic bottle jacks.

Two 10-30 ton hydraulic bottle jacks are also needed to re-level a mobile home. You’ll want to place the jacks at crossbeams, at the hitch, or the axles. Steel jacking plates are good ideas as well.

Wedges made of pressure-treated lumber or hardwoods like cedar are also needed along with basic tools such as a hammer and hand saw. Having a few 2X8s and 1x8s handy isn’t a terrible idea.

Temporary supports to use while jacking the home up are also needed. You’ll need large wooden blocks such as 6x6s that are as long as the home is high.

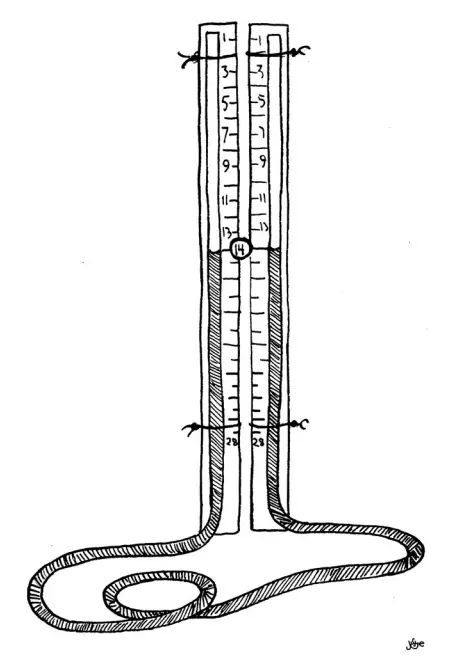

What is a Water Level?

In its simplest form, a water level is just a long tube with water in it. They can be called Egyptian levels or a Bunyip level. You stretch the tube from one side of the home to the other and make sure the home is at the same height as the water is level with each other. It doesn’t have to be perfect but it does need to be close.

There is a video at the bottom of this article that shows you how to make a water level. Otherwise, you can buy one at Amazon. They have a cheapo tube for $10 or a better one that can be used by one person for $58 (but you can make your own for a lot less). Laser levels may work but I can’t find any info about using them for mobile home releveling (affiliate links).

How to Build Your Own Water Level

This video shows how you can build your own water level. You probably don’t need to go as tall as he did unless your home is that high.

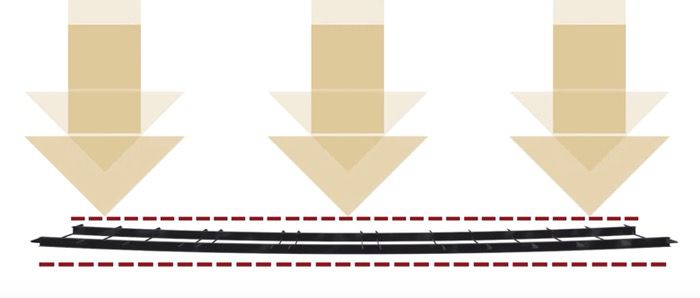

Understanding the Cambered I-Beam

I mentioned the mobile home didn’t need to be perfectly level in the section above. In fact, it probably can’t be perfect. Mobile homes sit on a steel I-beam that is slightly curved before the home is attached to it. This is called pre-cambering and it is done so when the home is attached to the beam its weight distributes and makes the beam level (there’s a lot more to this but this is the quick version). The camber will be different for each model or floor plan.

This curvature will affect the level of the home so you will probably not be able to get it perfectly level.

Pier Stack, Pier Plans, and Footers

All manufactured homes are installed based on instructions in the mobile home’s manual.

Piers or pier stacks transmit the home’s vertical load and transfer it top the footers. Piers are vital to your home and they should all be in good condition.

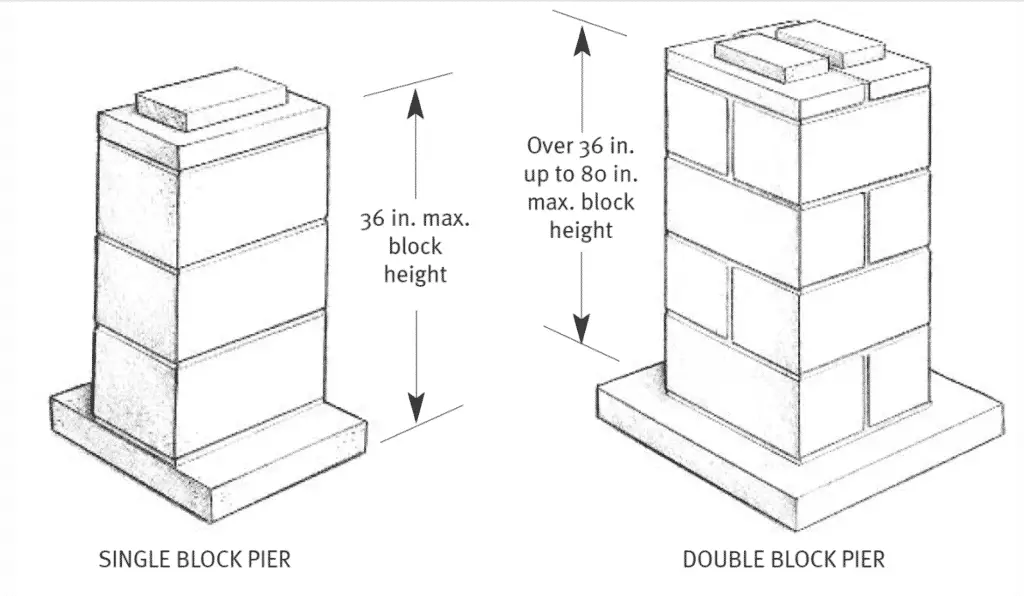

HUD code requires different piers based on the height between the ground and your home. If the home is over 36″ high the pier stack must be double interlocked concrete blocks. If it’s over 80-inches, the pier stack must have concrete and rebar in it.

Wedges

Wedges are 3.5″ by 5.5″ and used to adjust the height of the home just a bit at a time. Two opposed wedges will sit atop a 2″ wood board. The wood board sits on the concrete stack. The wedges can be hammered in or out to manipulate the height of that area ever so slightly. Like all wood, these boards and wedges can suffer rot and termite damage. They can also split and break.

HUD requires that wedges be installed across the grain on a manufactured home pier stack. Oak is a popular wedge wood for mobile home leveling. Cedar is too. Some installers like to use softer woods so they get crush just a bit so they can’t shift or slide. This isn’t a great idea so homeowners need to check on these regularly.

While you’re under your home be sure to check on the mobile home’s insulation and belly board.

How to Re-Level a Mobile Home

First, let’s look at a healthy foundation pier. In the image below you’ll see 2″ block of wood and 2 wedges which are perfectly within HUD code. Also, notice the mobile home’s underbelly is intact and the tie-downs are taut.

Re-leveling a mobile home isn’t difficult per se but it is a lot of work and very physical because you’re crawling all under the home. Once you have the water level you’ll need to determine the highest point on all of your steel beams or chassis.

This video show a single wide that is over 6″ off from high point to low point:

After finding the high point on the water level you’ll use a heavy-duty hydraulic jack to lift the home up to the highest level and even with the water level. This video shows that process:

If you have doors or windows that are hard to open, It’s recommended that you have someone in the home checking to see if windows and doors are easier to open and close as you re-level the home.

If you have doors or windows that are hard to open, It’s recommended that you have someone in the home checking to see if windows and doors are easier to open and close as you re-level the home.

(Note: I do not know anything about the company in the videos – I just found their videos and thought they would be a good resource to share).

How to Repair Loose or Missing Wedges

Use the bottle jacks to raise the home just enough to be able to remove the damaged or loosened wedges. Check your level to ensure you add just enough new wedges to get that side of the home level with others. Ideally, you’ll start with the lowest piers and work up to the highest but that’s not always possible.

Follow HUD Guidelines

HUD guidelines state manufactured homes cannot have more then 2″ of wood on top of concrete excluding the 2 wedges. It also requires that only pressure-treated wood be used within 18″ of the ground. C-90 or C-145 concrete blocks are the standards.

So if your block set ends up with 2″ of wood and the 2 wedges put together are 1.5″ this is acceptable in keeping the home compliant and HUD-certified. Very important to keep home in compliance with HUD or you can lose the home’s HUD certification and cause infractions in future sale home inspections.

This company out of Colorado recently posted several great videos showing the process of re-leveling a mobile home. You’ll see them using the water level and the hydraulic jacks to position the home and then adding supports.

Hiring a Contractor to Re-Level Your Mobile Home

If your home has more than loose or damaged wedges you will need to hire a professional to re-level your home.

To find a qualified company, ask the dealership that sold you the home. Manufactured dealers either have an in-house installation crew or they hire an outside company. Next, call your local mobile home supply company. You can also research on Facebook or the web. Regardless of where you find them, make sure their license, insurance, and bond are valid.

Getting recommendations from other homeowners who have had their homes re-leveled is also a good idea.

Be sure and ask the prospective company questions. Find out who is actually doing the re-leveling, what their experience is, and what their qualifications are. Ask for contact information of previous mobile homeowners they’ve worked for.

Get a quote or appraisal for the cost and the time involved. Get it all in writing. Here are 10 Foolproof Tips for Hiring Home Improvement Professionals.

How Much Does it Cost to Have a Pro Re-Level you Mobile Home?

In large metropolitan areas you can expect to pay around $500 to have a single wide re-leveled. Double for double wides. In less commercialized areas it should be lower, closer to $250-300.

Lonnie from Rocky Mountain Mobile Home Transport gave us lots of tips about re-leveling a mobile home. He says that experienced professionals can usually relevel an average 16’X80′ single wide that is out-of-level in about 2-3 hours. That includes checking and readjusting each and every block set. If there are broken concrete blocks that can add to the total time depending on how accessible getting under your single wide is.

Ideally, a professional should open up 3-4 skirting panels on each side to access the entire length of the frame rails. This gives them the ability to check and adjust each block set. Make sure whoever is doing your relevel is using a water level, hydraulic bottle jacks and have plenty of 2×6s, 1×4s, matching wedges, and extra concrete blocking (both full blocks and flat solid blocks) on hand.

Lonnie continues, “Don’t fall victim to re-leveling companies that crawl under your home and pound the blocks a few times and then expect you to pay them. They are ripping you off and should be fired without pay.”

In Conclusion

There’s no doubt that smaller homes are easier to care for and maintain. Manufactured homes have generally has the same upkeep and maintenance as a site-built home, except for a couple of things such as re-leveling a mobile home.

As always, thank you for reading Mobile Home Living!

Note: This article was originally published on Sep 2, 2014, and updated on June 15, 2019.