If you’ve ever read the government published pamphlets about a mobile home underbelly or how to repair a mobile home belly board you’ll quickly notice that they aren’t particularly worried about cost. Every recommendation usually ends with ‘hire a professional.’ Unfortunately, regular mobile homeowners have budgets and we can’t just call up a pro every time we need something fixed. For us, it’s either DIY or not at all.

In this article, we cover how important the underbelly of your home is and how to repair a mobile home belly board.

- Belly Board Vs Underbelly Vs Vapor Barrier

- How Does a Belly Board Get Damaged?

- Damaged Vs Healthy Underbelly and Belly Board

- How to Repair a Mobile Home Belly Board

- Step 1: Remove the torn insulation and black belly board

- Step 2: Reseal or Replace the Ductwork

- Step 3: Inspect Plumbing

- Step 4: Install Insulation

- Step 5: Install the New Belly Board

- Misc Tips

What’s the Difference Between a Belly Board and an Underbelly?

The terms belly board and underbelly are a bit confusing because they are used interchangeably.

Like most everything involving mobile and manufactured homes, the underbelly and belly board goes by several different names. The underbelly is also called belly board, belly wrap, rodent barrier, bottom wrap, bottom board, belly, belly barrier, and in some regions, Cemplex.

Underbelly

The underbelly is technically the area that the belly wrap covers. It starts at the bottom of your sub-floor or decking and goes to the top of the belly board. or black sheeting. This includes the chassis, floor joists, insulation, HVAC venting, wiring, and plumbing. Though, some people also consider the piers and footers, tie-downs, and vapor barrier as part of the underbelly.

Belly Board

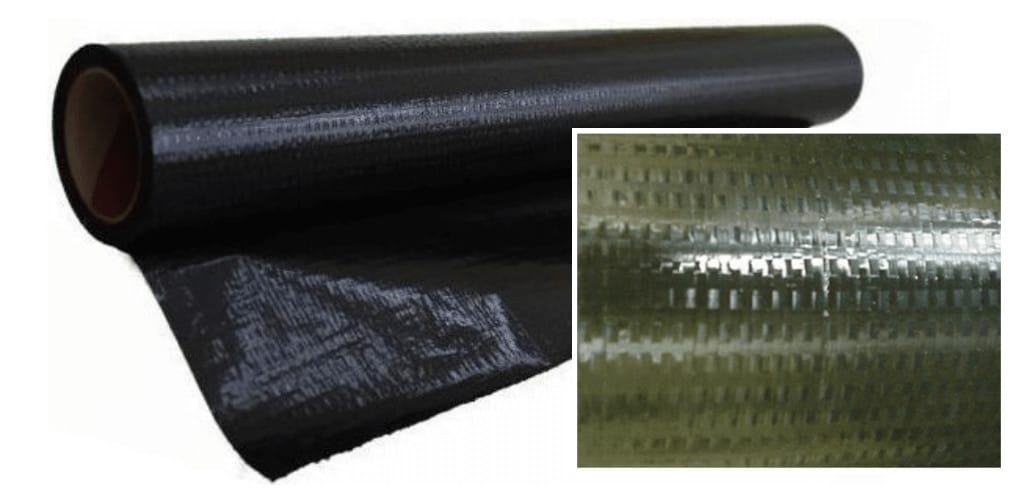

The belly board or belly wrap is the black material made of polyethylene sheeting. You can see the special weaving in the following photos:

The belly board looks like black plastic but it’s actually much stronger. It has fabric weaved into it so animals can’t easily tear it. It also has chemicals weaved into it that animals don’t like. The underbelly material is manufactured in a way that allows the correct airflow and circulation to prohibit condensation, mold, and mildew.

Image Source: R and G Supply

What’s a Vapor Barrier?

Vapor Barrier: There is also a vapor barrier which is an entirely separate thing from a belly board. The vapor barrier lays on the ground and helps keep the moisture that rises from the ground away from your mobile home.

A vapor barrier is another item that is much more important than many mobile homeowners realize. It should be installed if the home doesn’t have one. HUD recommends that the vapor barrier extend at least 6 inches from the perimeter of the home. This also helps keep weeds down which helps the skirting from getting damaged from a weedeater.

How Does a Belly Board Get Damaged?

Damage to a mobile home underbelly is most commonly caused by animals and people making repairs. That’s why it’s important to make sure any person that works on your home repairs the underbelly after they finish. This needs to be mentioned while the job is being negotiated. Make sure they repair it properly with the correct material.

A Damaged Underbelly Creates Several Issues

Does your mobile home look like the photo below? If it does, you need to get it repaired as soon as possible.

Four things are happening (or have happened) when a mobile home belly looks like this:

- a lot of heating and cooling loss is likely occurring wherever the insulation is missing or damaged

- critters can get direct access to the home

- plumbing lines are more susceptible to freezing

- the floor joists and subflooring has no protection from moisture

Should You Buy a Mobile Home with a Damaged Underbelly?

If a mobile home underbelly looks like the image above you need to do an in-depth inspection before you buy it. If you are looking for a turn-key home you probably should pass unless you get a really good deal and are prepared to spend the time and money to repair it.

The underbelly of a mobile home is vital to the entire structure. In fact, the underbelly is so important to a mobile home that a buyer can accurately gauge the home’s overall health by the condition of the underbelly. It’s as important as the roof.

We recommend you look under the home before you even go inside. The condition of the home’s underbelly and belly board will tell you a lot about the home. If it looks like the image above the home has probably not been maintained or kept up like it should have been.

The image above is how a mobile home underbelly and belly board should look. Since the home is sitting on a concrete slab it doesn’t need a vapor barrier.

How to Repair a Mobile Home Belly Board

Repairing or replacing a mobile home underbelly and belly board is a tough job. It’s tedious and frustrating to work with such a large piece of material while under a home but it can be done with some careful planning and help from friends and family.

Install the Vapor Barrier

Before you begin you will want to lay down the ground moisture/vapor barrier. This helps protect you from getting nasty while under the home.

Inspect the Entire Underbelly for Damage

Before repairing or replacing the belly board, you’ll need to inspect several things: First, inspect the entire underbelly: chassis, floor joists, insulation, ductwork, and subfloor.

You’ll need to repair the HVAC ducts and make sure they are sealed properly. Then install insulation under your home, and finally, install a new belly board. This article should help you with the last part. Plumbing and wiring will also need to be inspected and repaired if damaged.

Step 1: Remove the torn insulation and black belly board

First, everything has to be removed. The old insulation and the black belly board will need to be carefully cut out and taken away so that you are left with just the chassis, floor joists, HVAC ducts, plumbing pipes, and the subfloor.

First, you will need to remove and discard the old insulation and belly board. Once everything is removed you can start repairing and replacing each element one by one.

Step 2: Reseal or Replace the Ductwork

Next, you will replace or reseal the ductwork. Make sure all the corners and seams have been taped together or replaced.

Step 3: Inspect Plumbing

Next, you’ll want to make sure your plumbing is healthy. This is a great time to run new water lines. You can always cap off the old lines and run the new pipe (PEX) right beside the ductwork. If you live in a cold climate it’s a good idea to run your water supply lines beside the ductwork so the heat can help them from freezing.

Step 4: Install Insulation

Next, you’ll want to install new insulation. There are a few different methods and materials available. Most people like to use batts or rolls of insulation but foam board insulation is a good choice too. Read our insulation guide here and our underbelly foam board insulation tutorial here.

Step 5: Install the New Belly Board

Once the insulation is installed you will replace the belly board or the black plastic/fabric material that encloses the entire home.

If your belly board is present but has holes you can patch it with a few different products. There are zipper patches for areas that you need to access more than once. Tape is also a good patch material, just cut to length and keep adding it till the hole or rip is covered.

Here’s a great video showing how to repair holes in your plastic belly board:

Misc Tips

You can buy a product called the Trap Flap for areas in your belly board that require easy access. It’s just a piece of belly board with a zipper on it but it could be useful.

I once read a tip about repairing and replacing mobile home belly board that kinda made sense and kinda didn’t. I’m sharing it with you because it could help.

One of the reasons that many homeowners don’t like to have a belly board installed under the home is the difficulty when it comes to repairing plumbing or ducting (or even wiring).

Belly board also makes finding a water leak difficult. One installer recommends taking a small safety pin and pushing through the belly board a few times under bathrooms and kitchens. This makes moisture or wetness easier to see, especially if you have a nice dry vapor barrier on the ground. You may be able to catch leaks a little quicker.

This could be a terrible idea for bug-prone or extremely wet areas though. Just thought I’d share the tip.

Can you Use Tyvek as a Mobile Home Belly Board?

If you’ve read other mobile home blogs or the University of Wyoming’s booklet titled Mobile Home Energy or even the US Department of Energy you’ll see a recommendation using Tyvek to repair belly board.

Here are their steps to repair a mobile home belly board with Tyvek:

To repair large holes in the belly board (generally in the central part of the belly between the two main steel beams) use the following procedure:

First, measure the space needed to be covered. Cut a piece of Tyvek that is at least 1 foot larger than the hole on all sides. If the hole is really large, wrap one edge of the Tyvek around a long 1×2 inch furring strip.

Screw the 1×2 to the bottom of the floor joists next to one of the steel I-beams. Drape the fabric under the main duct trunk line so that space for insulation remains. Wrap the opposite edge of the replacement fabric to another 1×2 furring strip, then screw it to the joists next to the other metal frame.

Glue and stitch the other two sides of the replacement fabric to the existing belly.

If you do install Tyvek instead of the true black belly wrap make sure the Tyvek is facing the correct way. The reason we install vapor barriers and belly board is to keep moisture from penetrating the home and Tyvek allows a home to ‘breath’ so to speak. Also, Tyvek doesn’t have the oil additive that keeps mice from chewing on it like real belly board.

With that said, I think any kind of belly board, whether it be foam, Tyvek, or just blue tarps stapled up is better than nothing (blue tarps should only be temporary).

As with all mobile home construction and repair topics, everyone will have a different opinion. Get information from a few sources on the topic you’re researching if possible. Of course, if you have any questions just leave them in the comments below and I’ll try to help.

As always, thank you so much for reading Mobile Home Living®!

Thank you so much for this article. We desperately need repairs on our ductwork, insulation and belly board. We have basically gutted and rebuilt most of the inside of an older mobile home and are over budget. Since day one I have been saying that we absolutely need these repairs but no one who has worked on our place seems to understand. Even a contractor who regularly works on mobile homes in our area seems baffled as to what needs to be done. I love what we have done inside and want to protect it. Thank you. Any suggestions on finding someone who can do this work?

Hi Kim!

Glad it was helpful for you. I wasn’t really aware of the importance until I kept reading all the manuals and books. Every one of them stressed the importance and it makes sense, you don’t want moisture or critters to reach the insulation and all the other stuff under there.

Unfortunately, it’s really hard to find anyone that is willing to work on mobile homes and especially if it’s a job that requires going under a mobile home. A handyman or a manufactured home installation company are probably your best bet.

Best of luck! Let me know how it goes!

Hi Crystal, I have enjoyed reading your articles! Today belly board repair suggestion, blue tarps…..thanks much and more. That is better than nothing.

Hello Ms. Daryl,

Ideally, you need to use the black polyethylene sheeting but if you don’t have anything else, use what you can. Polyethylene sheeting can be expensive so it will work till you can save up. Thanks!

Had a flood in our mobile home and the underbelly was sliced to let the water out and the insulation got wet.

Can you recommend someone in the Middle River, Maryland 21220 area that are experienced to do this type of repair work. Insurance has given us an estimate and is paying for the repairs. Just don’t know where to start finding a professional experienced person to do the work. Thanks so much for any help you can give.

Hi David,

I cannot personally recommend anyone but maybe a reader will see your comment and help. I am working on getting a national directory/review site for professionals that will work on mobile homes but it’s not ready yet.

I would call your local mobile home supply store or even local dealerships for recommendations. Best of luck!

I desperately need help in Northeast Oklahoma with a Solitaire doublewide that had the roof completely ripped off my straight line winds – long story but I have a new roof but it is like my home is splitting down the middle along the marriage seam. I can’t find anyone to help with re-leveling or whatever it is that I need. Has anyone else had this problem and if so can you give me any advice?

Hi Cathi,

Call your local manufactured home dealership or supply house/store and ask them for a licensed transport and re-leveling company. I Googled for you and there are a few results you may want to call. Best of luck!

Please help, we recently had a water pipe burst and run into the belly board and soak the insulation. what are the steps to remedy correctly.

Hi Rhonda,

It really depends on how wet the insulation got. If it’s salvageable you should be able to use large fans to dry it out and then seal the belly board back up. However, if it was already old and then got soaked it may be easier to just replace the insulation. You’d certainly get better r-value with new insulation and probably lower your heating and cooling costs in the process.

I’d take this opportunity to go ahead and replace the insulation if it were me (assuming I had the money to spend). Best of luck!

Thank you Crystal !

I’ve been dreaming of mobile home living for a very long time and enjoy your website soooo much! Thank you for providing such useful information, well thought-out and thorough articles. Because of southern California park prices, I know what I buy will be older and possibly need repairs. Hopefully, not too extensive, but I understand things don’t always present themselves during inspection. I first got hooked on your site because of the makeovers, but found you provide so much more – things like this subject of belly boards! LOL, I know me, and I know I won’t be underneath doing the work.

Thank you so much for everything!

Thank you, I’m really learning some great information from fine folks like you!! I recently purchased an older 14X48 mobile on its own land that needs a lot of work before I can move into it. I’m doing most of the work myself and all of this info is invaluable!!

Thanks for the article. This site has helped me so much. I jumped the gun, buying our first (mobile) home. I didn’t realize how much work I was in store for lol… I have a question: My mobile homes is from The 80’s. The belly board is good until you get to one side of the mobile home. It is torn and hanging down the side of the home. I bought some tape-like material made for it. Are there any other steps I need to take, besides just pulling up that sagging/hanging side and attaching it again?

First of all, thank you for your work on this site, I really appreciate all the helpful articles and the candor. My question is about the term belly ;oarc. I have a 1976 single wide BUDDY and live in Northern Nevada. My belly board is actually a board. It’s like a pressed board. It seems to serve as a vapor barrier and rodent barrier, although I’m not sure how effectively. I have all kinds of openings which I’m working on depending on where it is. But the one problem I have is all along the perimeter the board has pulled away from the outside joist. Its been attached with large staples most of which were just improperly installed, meaning the staples didn’t make contact with the wood. Supposedly this place was made after the 1st HUD guidelines, but I really wonder

The workmanship is shoddy to say the least, on top of the plethora of prior owners doing really weird things, I’m dealing with one problem after another. Any ideas? Oh and the space between the ductwork and the bellyboard essentially there is no space so the insulation is smushed in there which reduces the r factor. So I’m not sure what to about that . The prior owners put 3 inch screws to attach new flooring and went right through the heating duct. They also moved the toilet and placed it right in the middle of the duct. They never even sealed the holes so the first year I was hear I was freezing but it was warm down below. I sealed it up and the next year my pipes froze! And only then did I realize the shutoff valve is under the house. Yes, the main is down there too, but so is an additional shut off valve next to the toilet. But no valve above the floor, thank God the toilet doesn’t overflow.

I really had to laugh. What an idiot! Yes! I am a perfect example of what not to do when buying a mobile home for the first time and never having lived in one. I had no idea what to expect and what to look for. I didn’t even know how to get under the trailer, let alone look under it prior to purchasing it.

But it is a roof over my head. And it is mine. And affordable. I’ll never be able to afford owning a house, let alone market rent, so I really don’t have any regrets.

Any information would be appreciated

I recently bought a 1981 manufactured home Can I ad insulation and foam boards with out removing the original belly wrap,as an extra insulation.

Who can come to our manufactured home in North Phoenix to fix everything underneath including the belly wrap and the damaged ac ducts and the plumbing leak???

Thanks!

Hello Jett,

Did you find someone in Phoenix to do your under belly and repairs? If so, can you share who and were they good? Hopefully not too expensive,, I live in Glendale and I am in need of repairs too. Thank you.