If you insulate under a mobile home you can save money. Over the last 3 decades, the National Renewable Energy Laboratory (NREL) has partnered with the US Department of Energy to test various methods of energy efficiency for old and new manufactured homes. Adding better insulation to the walls reduced heat loss by 13%. Coming in a close second was adding better insulation to the underbelly, under the sub-floor but above the belly wrap. It reduced heat loss by 11%. Installing storm windows also decreased heat-loss by 11%.

As with most everything involving mobile homes, there is confusion surrounding the mobile home underbelly or crawlspace under the home. One reason for the confusion is the numerous names used to describe the same thing. Mobile home belly board is also called a mobile home belly wrap, underbelly, bottom wrap, bottom board, belly, and belly barrier. Regardless of the word you use, it needs to be well-insulated.

In this article, we cover the best materials and method to insulate under a mobile home. We also share how one couple insulated and repaired their own mobile home underbelly using foam board.

Blowing Insulation into the Belly of your Mobile Home

As we shared in our complete mobile home insulation guide, blowing insulation into the belly and the ceiling of a mobile home is the most recommended method to insulate under a mobile home.

However, this method of insulating a mobile home underbelly requires specialized equipment and advanced knowledge of a mobile home’s construction. Therefore, blowing insulation can be expensive. Fortunately, there are many state and local government programs that may help mobile home owners to add insulation via energy grants and low-interest loans.

Depending on your location you may qualify for a program or financing help to get your mobile home insulated better, especially if it was built before 1976.

Top Materials to Insulate Under a Mobile Home

While blown insulation is the favorite method of insulating a mobile home underbelly it is also expensive because you have to hire it out. Using foam, fiberglass, or Rockwool panels gives the homeowner the opportunity to DIY which is usually always a cheaper option.

Spray Foam

Spray foam is most recommended for already enclosed areas such as the walls or ceiling/roofing of a mobile home. It’s fairly expensive because you have to have special equipment.

Spray insulation can be made of a variety of materials. Most common is cellulose (newspaper), foam, and fiberglass. Learn more about spray foam here and here.

Advantages of Foam Insulation

Foam insulation has many advantages. Here are just a few:

- easy to cut with a utility knife, hand saw, or table saw

- lightweight and easy to carry

- flexible enough to easily maneuver into tight spaces – DIY friendly

- doesn’t promote mold growth

- water resistant

- long-lasting – won’t decay

- insecticide is used on most foam making

Since foam board can also act as both an insulator and a vapor barrier for your mobile home it’s ideal to install under your flooring.

Disadvantages of Foam

Fire is probably the biggest disadvantage of foam board insulation and meeting your local fire protection codes may be bothersome. Foam is fairly hard to ignite, but once it catches it emits a dense smoke and toxic gases. However, some manufacturers spray the foam with fire retardant. You’ll want to research your local codes.

Three Common Types of Rigid Foam Insulation

The three most common types of foam board are made of polystyrene, polyisocyanurate, and polyurethane. All are petroleum-based products.

Rigid foam can be used in walls, roofs, and foundations, for retrofits or new construction. Most varieties of foam have a higher R-value per inch than fiberglass, cotton, or cellulose. (Green Building Advisor)

Here are the three main types of rigid foam insulation:

Molded Expanded polystyrene (EPS or MEPS)

Expanded polystyrene is the most common type of foam insulation and the most affordable.

It is made from the same closed cell foam beads that your coffee cups and shipping peanuts are made from. It is molded, or extruded, into large sheets that can be used in roofing, flooring, siding, and other construction needs.

The R-value of EPS sheets depends on the density, with a single sheet of foam ranging from 3.6 to 4.2 per inch.

Extruded polystyrene (XPS)

Extruded polystyrene is very similar to expanded polystyrene but it uses pellets instead of beads, making it smoother and denser. It also has better water resistance. You’ll recognize this product by its colors – it comes in blue, pink, and green depending on the manufacturer.

You’ll pay more for extruded polystyrene but you’ll get better energy efficiency. The R-value of extruded polystyrene is around 5 per inch.

Extruded polystyrene is ideal for basements and slabs and makes an ideal choice for insulating under a mobile home if the added cost isn’t an issue.

Polyisocyanurate (ISO) and Polyurethane

Polyurethane and Polyisocyanurate have advantages and disadvantages.

They have higher R-Value per square inch but they are also the most expensive of the three types of rigid foam.

Foil-faced polyisocyanurate is more resistant to ignition than unprotected XPS or EPS. For this reason, some (but not all) building inspectors allow foil-faced polyisocyanurate to be left exposed on crawlspace walls or in attics without requiring a layer of drywall as a thermal barrier.(Source)

An advantage of polyurethane is the foil that covers the sides. The foil can act as a vapor barrier and is used most often in roofing and foundations.

Laurel and Bryan’s ‘Death Zone’ of Cold Air

The first year in a new home, especially an older mobile home, is always a learning experience. That was certainly true for Laurel and Bryan Adams when they moved into a 1974 Olympic single wide mobile home.

The couple’s new vintage mobile home had served Laurel’s aunt very well until she passed last year at the age of 93. While the mobile home’s decor may not have made it to the cover of Home and Garden, auntie had lovingly updated it over the years. She had heroically painted the walls herself with a three-inch paintbrush in bright yellow and aqua.

During their first winter in the home, they learned how much their utilities cost and where all the cold spots were located in the home. Needless to say, their 1972 mobile home had a few cold spots and their heating costs were too high for such a small home. The following Spring they began researching how to best insulate their home.

Laurel and Bryan decided to solve their problem energy loss using foam board. They were kind enough to share the details of their project with us, complete with hand-drawn images. How cool is that?

It was a sound, affordable home that had loads of potential!

The Adam’s vintage mobile home sits in Edmonton, Alberta, and since older mobile homes are notoriously under insulated, they experienced wild temperature fluctuations during their first winter.

How to Insulate Under a Mobile Home with Foam

Once Spring arrived, the couple set out to find a way to increase the home’s energy efficiency, especially in the ‘death zone’, as Laurel playfully called it. The death zone was an area 2 to 3 feet above the floor that remained much colder than the rest of the home.

Materials Used:

- 4′ x 8′ Foam Insulation Board

- Table saw and hand saw

- 3″ screws with 1″ washers

- Screwdriver (electric)

The Adam’s were able to buy their 4′ x 8′ insulation foam board from the manufacturers directly. That saved them almost half off the retail price. It pays to cut out the middleman whenever possible!

Insulating Under a Mobile Home with 2″ Foam Board

Related: 8 Energy Efficiency Ideas for Your Manufactured Home

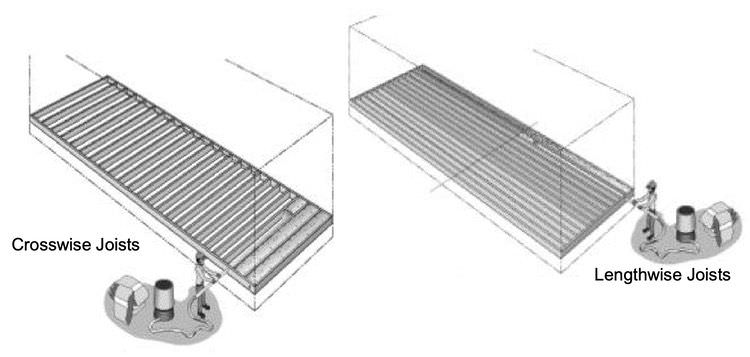

The mobile home’s floor joists are on 16″ centers, which means the wood floor joists are placed 16″ apart from each joist’s center point. Since the joists themselves are roughly 1.5″ wide the section between each joist was approximately 14.5″ wide.

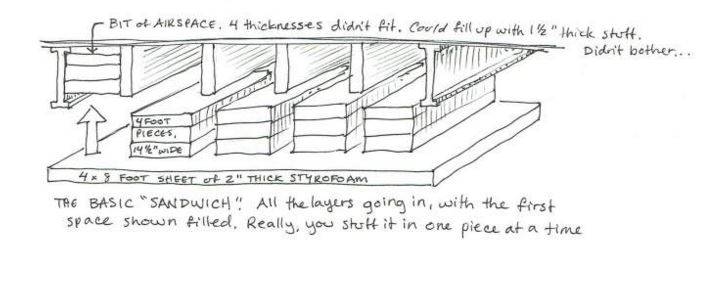

Bryan bought 2″ thick Styrofoam insulation board and used a table saw to cut the boards 14.5″ so that the foam was easy to push between the joists and stay put (there are 4″ foam boards available but the 2″ is easier to handle).

Bryan concluded that layering 4 boards together to create an 8″ total thickness of insulating foam would work best for their area’s average winter temperatures.

Each stack was made of three 14.5″ wide by 2″ thick foam boards. The fourth foam board was left full-size (4′ x 8′) and attached to the bottom of the wood joists. This holds the 3 boards above it in place and creates a total of 8″ of insulation under the entire mobile home.

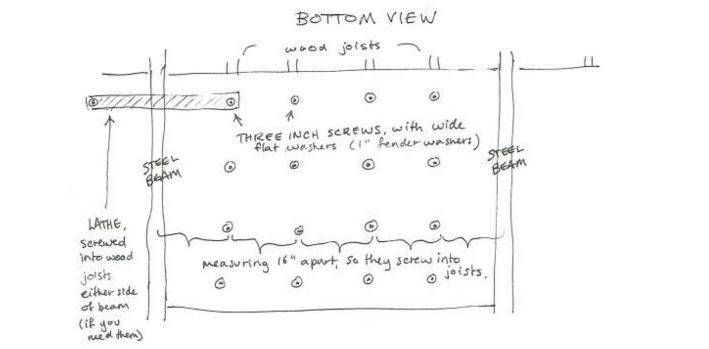

To secure the full-size sheet to the bottom of the home Bryan used 3″ screws with a 1″ wide fender washer. Since the home was built on 2 steel beams at an 8′ interval he used the lip of the steel beams to act as a shelf for the ends of the foam board. The wood joists are a bit shorter than the steel beams so this method worked well.

The drawing below shows it better than I can explain:

Laurel also drew a schematic of the screw placement. She explained that had Bryan not been able to screw into the bottom of the wood joists that he could have used a couple of different options to secure the foam. A thin wooden lathe could have been used as a bridge to hold the foam into place.

The results of the couple’s DIY insulation project has been a great success! Laurel states that the ‘dead zone’ is long gone and since the foam has insulated the duct-work under the home the forced air heat is reaching the end rooms better.

Using Fiberglass to Insulate Under a Mobile Home

Fiberglass is the most common insulating material. It is made of very fine strands of glass formed in rolls and loose fill batts that are installed between beams, joists, and studs.

Since it is made of glass it is an excellent insulator that is affordable, non-flammable, and water resistant. The downside is that it is fairly dangerous to handle. You’ll definitely want to use protection when working with fiberglass.

Depending on density you’ll get R-value ratings ranging from R-2.9 to R-3.8 per inch.

This is a great video that follow the whole project of removing and installing insulation under your mobile home:

Using Roxul Rock Wool to Insulate Under a Mobile Home

One expert recommended Roxul Rockwool for a few reasons. The following benefits are from the Rockwool website:

- Non-combustible stone wool insulation with a melting point of approximately 1177°C (2150°F)

- Fire-resistant due to its high melting temperature

- Water and moisture resistant; does not absorb moisture to maintain insulating value

- Chemically inert

- Does not rot or promote the growth of mildew, fungi or bacteria

- CFC- and HCFC- free product and process

- Made from natural and recycled materials

- ROCKWOOL® can contribute to earning LEED® points

Rockwool is a rigid mineral wool insulation sheathing board that is non-combustible, water-repellent, fire-resistant and sound absorbent

Different Opinions About Insulations

Some experts may frown on the 4.5″ left over from each 48″ wide board after getting 3 cuts. That seems kind of silly of a reason to not like a project as the foam can be used on a multitude of other things. You may even be able to get 2 or 3 different areas of your home insulated using the ‘waste.’

In the construction world you have the wrong way and the really wrong way. Everyone has an their opinion and everyone else is wrong. Ask 3 different construction exerts the same question and I guarantee you will get 3 different answers.

Related: Useful Mobile Home Repair Manuals

Installing a Ground Moisture Barrier

It is recommended that all mobile and manufactured homes have a ground moisture barrier. A barrier is usually just a polyethylene plastic sheeting placed directly on the ground and secured under the home to act as another shield between earth and home. it should extend 6″ past your mobile home skirting.

The ground barrier combined with a vapor barrier (whether via a separate belly wrap or foam installation) will protect your mobile home from moisture. It can also deter animals from going under your home and help you locate leaks and water issues as the water will sit on top of the plastic instead of soaking into the ground.

Check your Local Codes Before All DIY Projects

Inspections are a necessary evil in the construction world, regardless of what kind of DIY project you do. Every location, whether in Canada or America, has building codes that must be met for all update and remodeling projects. The location of your home will impact the codes that you will need to meet. Homes in Canada face different issues than homes in Florida so be sure to research your local codes.

Summary for Insulating Under a Mobile Home

Repairing and insulating under a mobile home (or the mobile home belly) isn’t the most exciting remodeling project but it can make a huge difference in your energy bills and your comfort.

Unfortunately, most mobile homeowners have no idea how important the belly of their mobile home is to the overall condition of their home.

If your home is losing heat or seems harder to keep heated or cooled you may want to consider insulating under your flooring as the first step in updating your home.

Insulating your mobile home with foam is proven to be effective. The foam is easy to use and fairly affordable for its high R-value and energy conservation properties.

Laurel states that she doesn’t think insulating the walls would have made nearly as much of a difference as the underfloor insulation has and she would know best, it hit -4 Fahrenheit last week and their home stayed warm and the death zone is long gone.

A HUGE thank you to Laurel and Bryan Adams for sharing their project and teaching us how to insulate and repair a mobile home underbelly. and to Laurel for the awesome drawings!

Learn more about a mobile home belly board and underbelly here.

Thank you so much for reading Mobile Home Living!

I would have used Tyvek house wrap instead of plastic as the insulation needs to breathe.

The venting is meant to reduce moisture build up. A lot of the mobile homes in the park I live in just have plywood skirting though some are upgrading to metal skirting only one has insulated skirting.

According to code requirements mobile home skirting must be insulated, and vented. This makes zero sense to me. What is the reasoning behind this?

Hi Rick.

I’m wondering how your project turned out? We are in the process of a similar install ourselves. We had pulled up the floor boards to replace flooring which made insulating easy. We used rigid foam boards as the underbelly protective exterior layer and then filled in between floor joists with traditional rolls of the pink fiberglass insulation. I’m also rolling our moisture nation tarp under the home.

Hey Dallas,

Mine is on a foundation and I’m in NS. and will be doing the skirting as well.

I just put insulation under my mobile home under plywood and sealed it with plastic. Just heard plastic will create moisture and mold now I am worried. Please advise.

Thank you

I READ THE ARTICLE ABOUT THE 8 INCH LAYERED BLUE BOARD.’

I WANT TO DO THIS … BUT IM WORRIED ABOUT CONDENSATION BETWEEN THE BLUE BOARD AND THE TRAILOR FLOOR. ANY COMMENTS WOULD HELP ME

THANKS

I can’t find a specialty company for love nor money in Williamsburg VA area – do you have any resources lists?

I am in Northern Ontario and have had spray foam done on the underbelly of my mobile home. Now I am wondering if I should also get insulated skirting. I have heard of possible moisture problems, and want to avoid that. Thanks.

Where were you in 1992? Bought our doublewide 28 x 40 with a 15′ addition on the end which added 2 more bedrooms and common closet. We had neighbors with cats and that winter six cats perished in-between the wooden floor joists and the underbelly insulation. That next spring we extracted the animals and cut all the underbelly insulation out and removed. We then installed pink insulation in all areas of floor joists not having ducts or waterlines near. Having metal frame rails on both halfs the rear half has ductwork coupled with waterlines. Made wooden standoffs hanging down almost the bottom edge of frame and made my own joists to attach insulation batts. In addition I added rabbit wire to underneath of joists to keep out varmints. This worked well until we decided to install ac unit. Not an ac thru the furnace directly, but outside standalone unit that is cut into the crossover insulation round ductwork that supplies home with hot air. Installed cold air return in hallway and we were done. Worked amazingly well until I looked underneath our home, ductwork was dripping water, I mean a path of 12″ wide 55′ long wetness under home on the concrete. Insulation was getting moldy, extremely dangerous. Underneath again bubble wrap insulation around complete ductwork, still getting huge amounts of water dripping leaving a path of water 55′ long. Ripped the HeatController unit out, ventilated underneath and bought a 25,000btu window unit 220volts. Extremely frustrating in the long run, now looking at mini splits as an alternative.

I am, currently, in the process of purchasing a mobile home in Palm Springs, CA. The inspection report says that there is not adequate insulation under the home. Due to the hot, and dry climate there, how important is it, to have this insulation?

Hi Beverlyann,

It’s best that you use insulation or foam around the pipes, not newspaper since there’s really no insulation qualities and it isn’t fireproof (and critters LOVE it). It is common to have to add insulation after plumbing upgrades or changes so that makes sense – just not the newspaper. You can get a roll of insulation for less than $30 and use whatever is left between the joists under your home. When they added the new pipe, they had to cut through the black plastic stapled to the bottom of the home. You can buy patches for that or just tape it if nothing else because that is your first line of defense against condensation and critters so make sure they fix that too.

Best of luck!

Water damage ruined my flooring in bathroom I upgraded my vanity after subfloor was done and flooring was put in but not leveled but I bought My vanity is new but they had to take it back out while it was in there were holes were the pipes were well I felt cold air they had to take it out to fix again the subfloor do vanity had to come out I said my home was weatherized a few months ago and never felt cold air I said u needed foam around pipes and it needs insulation, I saw that they put newspapers on hole so far but vanity isn’t installed yet is that enough insulation? And is it correct to have foam around pipes after job is completed? Need advice ASAP

Sorry about the spelling errors lol But love doing my own work!

Replacing is expensive if you have someone do it. I just did my own. I am a 63 year woman with not much exoerience at it. Watch you tube. So easy I didnt replace everything. i replaced where maintenance men and animals had been. Largest place about 4×3. I began with the pink insulation R19. I put it inside of studs. Used the insulation support rods you just push in. Staped some plastic pipe hange for added support. While in theier (this was under a bathroom) insulated my hot and cold pies with that one inch grey tubing insulation. Stayed perfectly. Pushed in some extra insulation loosely around piped for extra blanketed benefit. So it took me a couple hours but I wanted to do it right. So if you go on amazon you can order your original belly wrap material and the correct belly mending tape. The tape cpomes 4 to 6 inches. Perfect tape love it. You can also to patch cut the size material you need. Spray with 3M adhesive from Lowes, wait a couple minutes. Put patch up and smooth. perferct patch espaecially for smaller ares. But on amazon I bought belly wrap kit that included the mending tape( with super hold) for about 40.00. I love saving myself some money!

Hi Rick,

Congratulations on the new home! I’m from southern WV! It’s a beautiful state. So, I’ve always been told that you should always have a belly wrap and a ground covering. It’s at least another layer of protection from critters. However, you’ll would want to make sure you have ample ventilation.

I recently wrote an article about insulating a mobile home. In the energy guides I’ve read, they tested foam against the blown insulation and blown had a better R-Vlaue. I’d stick to the foam board, the pink rolls, or the blown in.

Take lots of photos – I’d love to share another beautiful WV home!

With foam board insulation, as in your January 17, 2016 article, and using a 6 mil ground cover under the home, do you need a separate belly wrap? My wife and I will be replacing much of the subflooring in the 14 x 48 singlewide we’re buying in WV, and figure we can do a lot of the work from above. With a rigid foam board bottom, could spray foam be used instead of the cut-down rigid sheets, or would we need to go to an exterior grade plywood bottom due to the thermal reaction of the spray foam? We’re going to replace the water lines with Pex, and go to interior wall-mount heat to replace the furnace, and thereby eliminate the need for ductwork for our small space. Thanks Crystal.

Thanks for this info!! Very helpful!

It depends how you install it. If you already have a skirt then I would recommend adding a better belly wrap or ground covering (using a ‘poly’material) over anything else. If you’d just hang the clear vinyl behind the skirt it would likely cause some ventilation and condensation issues and wouldn’t offer any true advantage toward r-value or wind/weather shielding.

I’d put the money on belly wrap more than anything.

(If I misunderstood just let me know).

I’m thinking about putting clear vinyl around the inside of my single wide skirting. What are any possible problems this might cause?

Hi Ray,

I’m not really knowledgeable about underbellys, I’ve only been around a couple of replacements. I do know that too much insulation causes a lot of damage. I know a guy that insulated his home so much that it didn’t have the proper circulation or ventilation and he ended up with a huge mold and mildew issue. And, I know the underbelly is absolutely vital to a mobile home and should be tear-free and sealed well so that critters can’t get in and heat doesn’t escape.

I’m not sure how the earth or sun’s energy, or heat, can impact the home from the bottom but I will say that anytime the word thermal is used on a product I get a little suspicious. Mobile Home Repair at mobilehomerepair.com may be able to help you more.

Best of luck!

Our park model home had a major water leak and needs the insulation and underbelly material replaced. The company I hired said they could upgrade the underbelly material with a thermal barrier. Question? Does anyone think this is a good idea.? Will it cause future problems? The insulation being replaced is R19 batt. Thanks, Ray

Hi Mike,

Definitely get the underbelly taped back up, you may be able to insulate the ductwork a bit in the process. Taping the joints and bends wouldn’t hurt a thing before you tape the plastic. You probably have to special order the insulated skirting if you can’t find a distributor. Google ‘insulated skirting for mobile homes in Wisconsin’ and you’ll likely find a website from the manufacturers and they usually list their distributors. You may have one local. Otherwise, you’ll either need to order it online or make it yourself.

Best of luck!

Hi Mike,

If you will Google your town and the terms ‘rapid wall skirting’ or gorilla insulated skirting’ you will find a couple of places. A store called Mobile Home Depot MI may be close to you. Otherwise, you may need to order it. Here are a couple of sites that may help you learn more about them:

Rustique Rapid Wall

Mobile Home Advantage

Everlock Skirting

(PS Make sure you put adequate venting when using insulated skirting.)

Best of luck!

Looking to purchase insulated skirting for my mobile. currently have skirting on. live in green bay Wisconsin

Having a hard time finding insulated skirting for my mobile. Currently have skirting on, live in Wisconsin where it gets a little cold sometimes. Any suggestions? Also gaps in the underbelly as well as visible ductwork.

Hi Cheryl,

There are a few different ways to install OSB (removing the metal or going under, or stripping and installing and bracing – it all depends). But, if the porch isn’t heated most homeowners will just go with metal (no OSB) to reduce cost. There are so many factors in play I can’t really answer this question.

Hello!

I’ve only ever seen 6 mils thick black polyethylene recommended for ground moisture barriers. I would think the felt would work though it probably costs more.

Any thoughts on something I read regarding using rolls of asphalt roofing, it might have said the roofing “paper” that goes under the asphalt, and just laying it out over the ground under the trailer to keep the ground moisture from being drawn up into trailer. I’m already using rigid insulation between the floor joists. Any answers would be appreciated! Thank you.

How do you install foam board insulation under a metal roof, enclosed a porch and contractor didn’t put OSB on before metal roofing

Hi Jane,

It’s tough trying to buy an older mobile home. Structure (framing, roofing, doors, windows, etc) and insulation are the most important aspects of the home. Installing new insulation will be a great investment though – you’ll definitely save on your heating and cooling. You can install the lower cost pink insulation to save a little money (and it’s a bit easier to install so you can save on labor, too).

Best of luck!

Thought I got a bargain on a 1967 single wide for23,000. After already investing 10,000. In cabinet, toilet, vanity and new deck looking underneath I see needed expense of insulation. Only beginning of August but can feel chill of nh air coming. Please help in merrimack nh

Sorry, Kayla, you will have to buy the insulation yourself.

How can I get insulation from the manufacturer? I am having difficulties figuring that out and I recently got a mobile home that needs some new insulation underneath, gotta cover like 1064 square feet and I cant afford to spend what lowes and home depot want

Hi Mary,

You will want to go to a contractor’s supply house and show them an old one. I found an online store that may have what you need but I just found them through Google so I know nothing about the company (but it may help you find the name of the clamp at the very least and you can go to Lowe’s or Home Depot and find them there).

http://www.supplyhouse.com/Clamps-Pipe-Hangers-Straps-1385000

Best of luck!

I have steel skirting and the clips that attach the panels have broken off – I cannot find them anywhere online. Any clues where I can purchase?

Yes. The foam is the insulation and the plastic sheeting will block condensation from the ground along with a few other important things. Definitely want both!

So you do the foam board and the underbelly sheeting? I just received a mobile home in fairly bad shape and am trying to fix it up while saving money at the same time.

Debra,

Unless I’m mistaken, you live in a place managed by the owner of the land, so i would ask them; they are the best people to start with. If not, then if you live in an area with many mobile homes like I do (seashore in New Jersey) there are tons of supply stores selling part. Go see them, and ask them who they know. Nest, ask your neighbors who they use for their repairs. All this assumes you live in “park”. Again, if not, I’m sorry and use Crystal’s advice and call around.

Bryan and Laurel,

Usually, tackling a project requires multiple sites and multiple opinions. Since I knew in my mind I had to insulate between the joists then cover that insulation, I set out to find help. I found the only instructions I needed, and it is so thorough, I can’t wait to get started this weekend. I bet one of you is an engineer.

Hi Debra,

If you have a local mobile home parts supplier call them and see if they know of anyone. A handyman service may be able to do it – it’s just a lot of crawling and stuffing! Best of luck!

I would like to no how do you get intouch with some that knows how to repair installation underneath a trailer with installation thats not to expensive to save energy at a good price .

This info is very helpful, Thanks

Awesome Sauce!!!! Thanks, we will use this information!!!!